Fruit vacuum packaging machine

A vacuum packaging machine, vacuum machine technology, applied in packaging, transport packaging, food packaging, etc., can solve the problems of waste, difficulty in connecting the suction port of the vacuum machine to the two packaging films, and unrealistic methods, and achieve the effect of neatly arranged packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with embodiment.

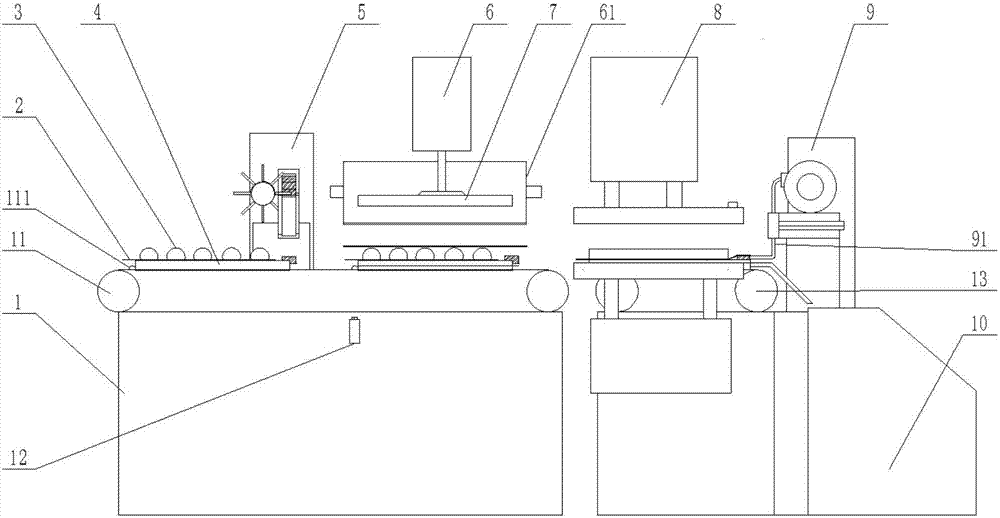

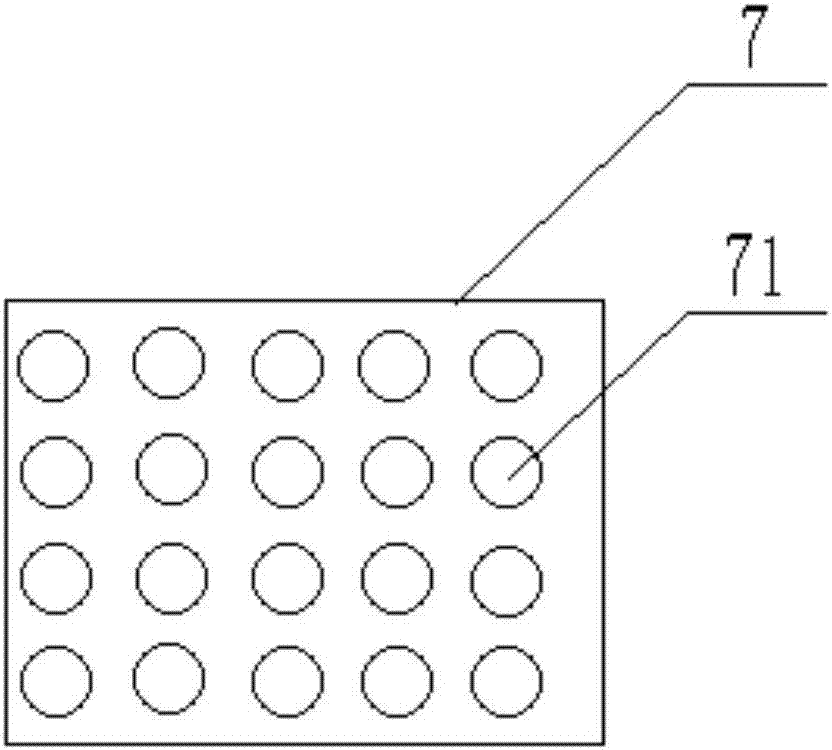

[0030] see figure 1 , figure 2 , in a preferred embodiment of the present invention, a kind of fruit vacuum packaging machine is characterized in that: it comprises frame body 1, and frame body 1 is provided with first conveyor belt 11 and second conveyor belt 13, and the first conveyor belt 11 and the second conveyor belt The two conveyor belts 13 are arranged at a distance and can be transferred. On the table of the frame body 1 along the first conveyor belt 11, a pressure-feeding device 6 , a heat-sealing device 8 , a vacuum machine 9 and an edge trimmer 10 are sequentially arranged. Lower die 4 is placed on the first conveyer belt 11, and lower die 4 is provided with fruit placement holes 41, and the fruit placement holes 41 are evenly arranged. There is a square packaging bottom film 2 attached to the lower mold 4, and the fruit 3 on the packaging bottom film 2 is placed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com