Negative photosensitive white ink for 3D cover plate glass and preparation method and application method thereof

A technology of cover glass and white ink, which is applied in the direction of photosensitive materials, inks, and optomechanical equipment for optomechanical equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

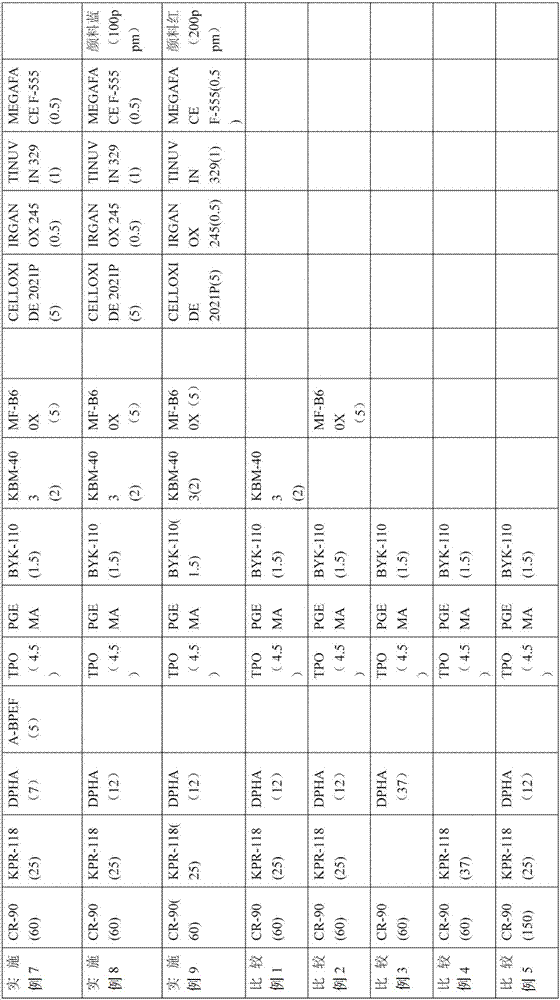

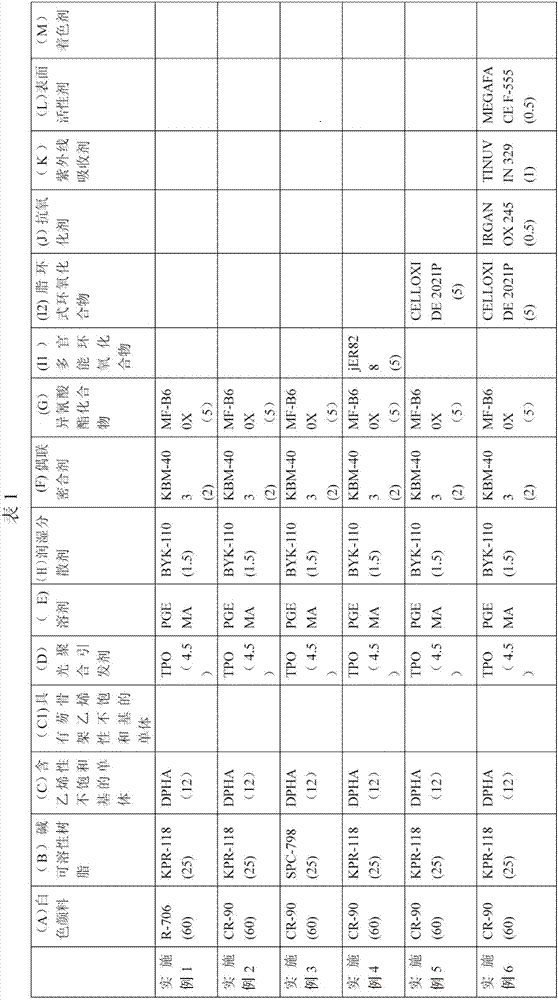

Examples

Embodiment 4

[0179] Examples 4 and 5 illustrate the strengthening of chemical resistance, water boiling resistance, and solvent resistance after adding epoxy compounds. Example 6 illustrates the enhancement of yellowing resistance after addition of antioxidant, UV absorber. Example 7 illustrates that after adding a monomer having a fluorene skeleton ethylenically unsaturated group, drug resistance and water boiling resistance are enhanced. Embodiment 8 and embodiment 9 are to add coloring agent and carry out toning.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com