Pulley part quenching device

A technology for quenching devices and parts, applied in the direction of quenching devices, furnace types, furnaces, etc., can solve problems such as large limitations and parts specification restrictions, and achieve the effect of improving the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

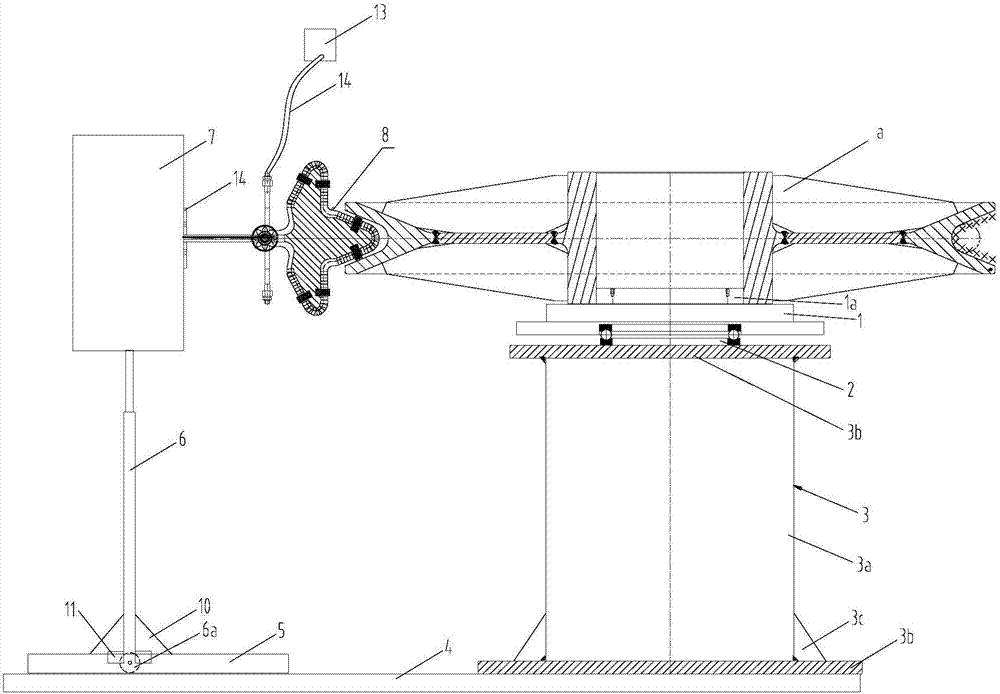

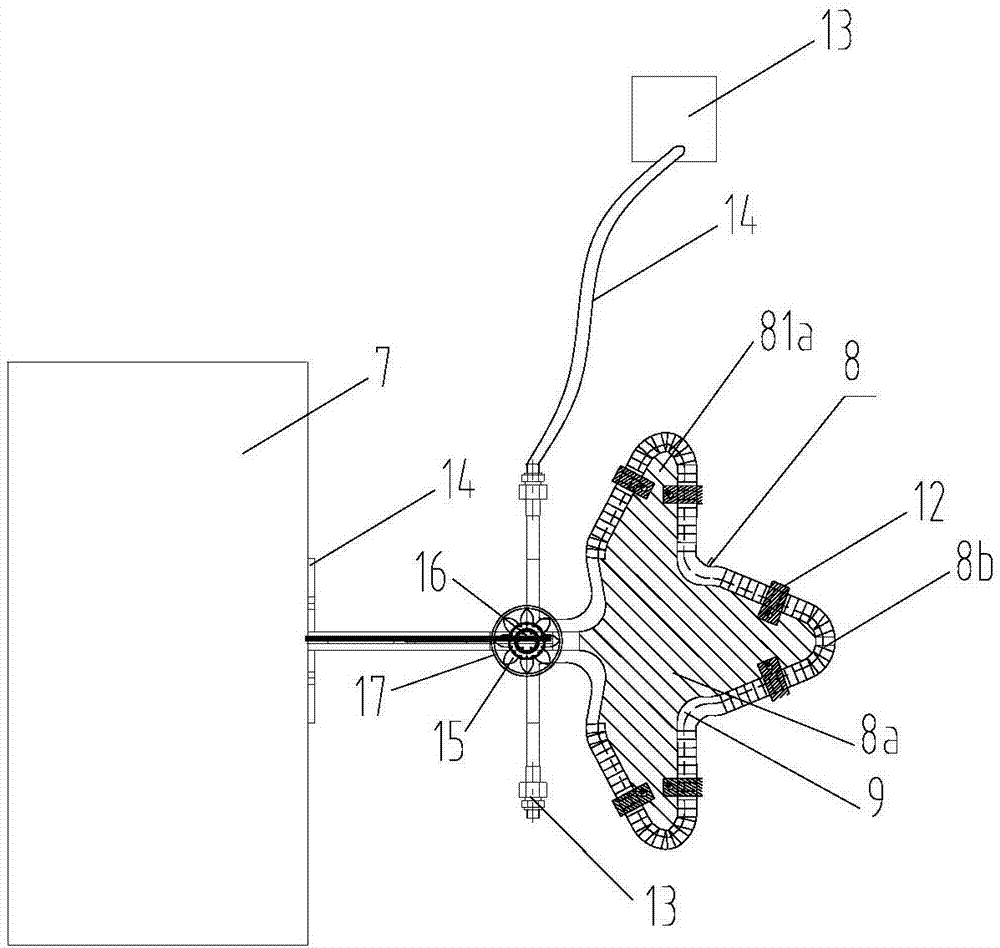

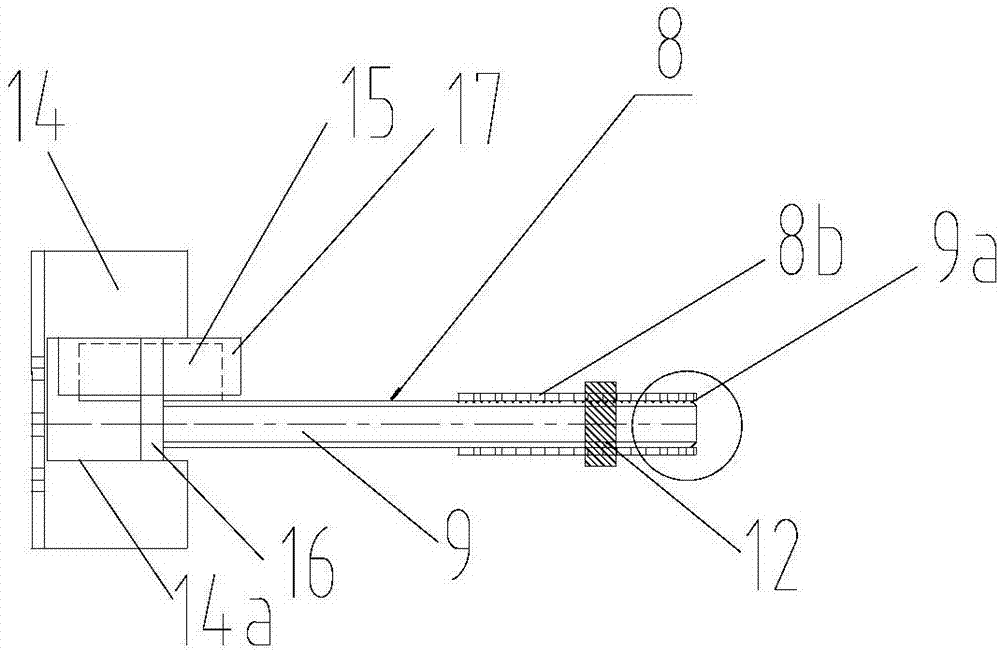

[0028] The embodiment of the present invention provides a pulley part quenching device, such as figure 1 As shown, the quenching device for pulley parts includes an inner turntable 1 , a base 3 , a bottom plate 4 , a lifting rod 6 , an electromagnetic induction heater and a mounting seat 14 . The inner turntable 1 is rotatably installed on the top of the base 3. The inner turntable 1 is used to clamp the part a to be quenched. The base 3 is fixedly installed on the bottom plate 4. One end of the lifting rod 6 is slidably arranged on the bottom plate 4. The lifting rod The sliding direction of 6 extends along the radial direction of the inner ring turntable 1. The electromagnetic induction heater includes an induction device 7 and an induction head 8 . Induction head 8 (see figure 2 ), the induction device 7 is installed on the other end of the lifting rod 6, and the induction head 8 is arranged toward the inner turntable 1. Mounting seat 14 is installed on induction device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com