A triboelectric separator filled with packing friction plate

A technology of filling fillers and friction plates, applied in electrostatic effect separation, solid separation, chemical instruments and methods, etc., can solve the problems of poor sorting effect, poor economy, easy charge dissipation, etc., to improve processing efficiency and flexible equipment installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

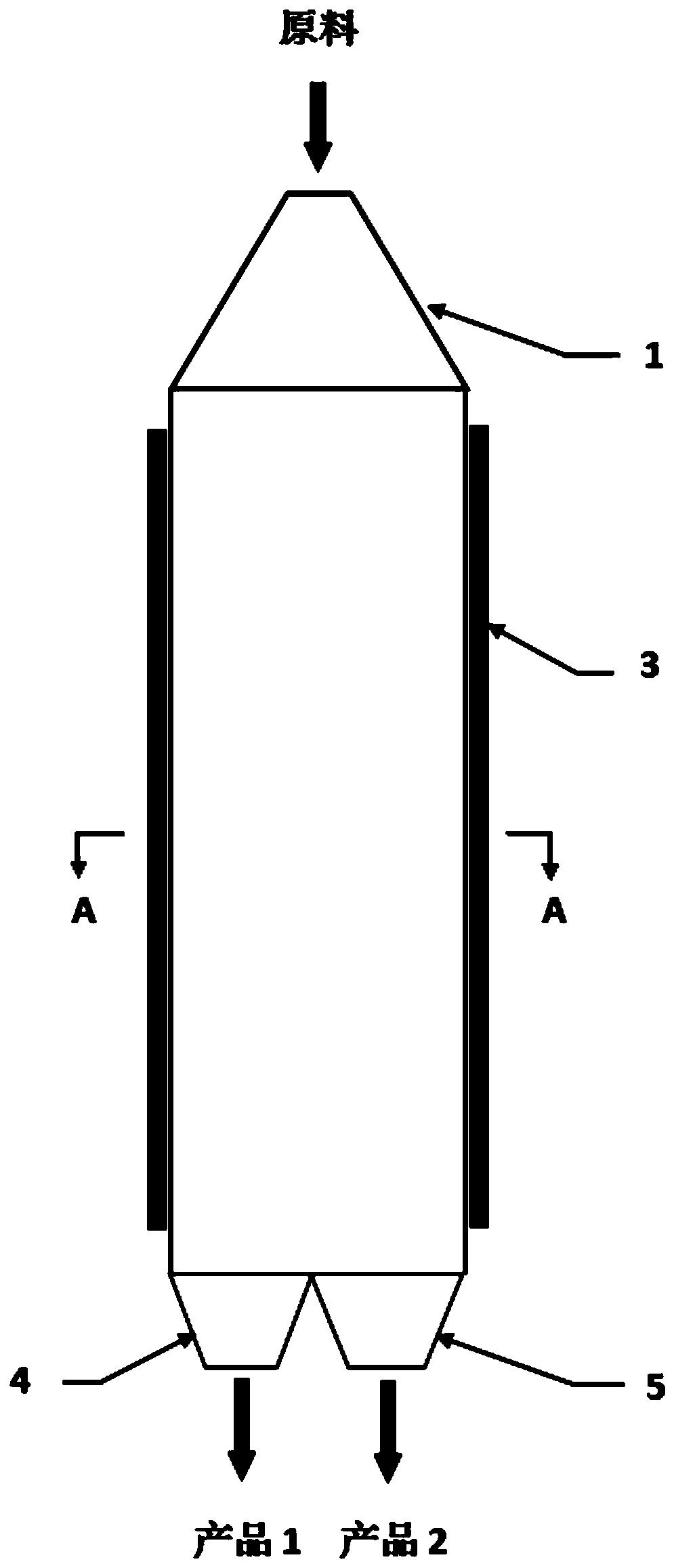

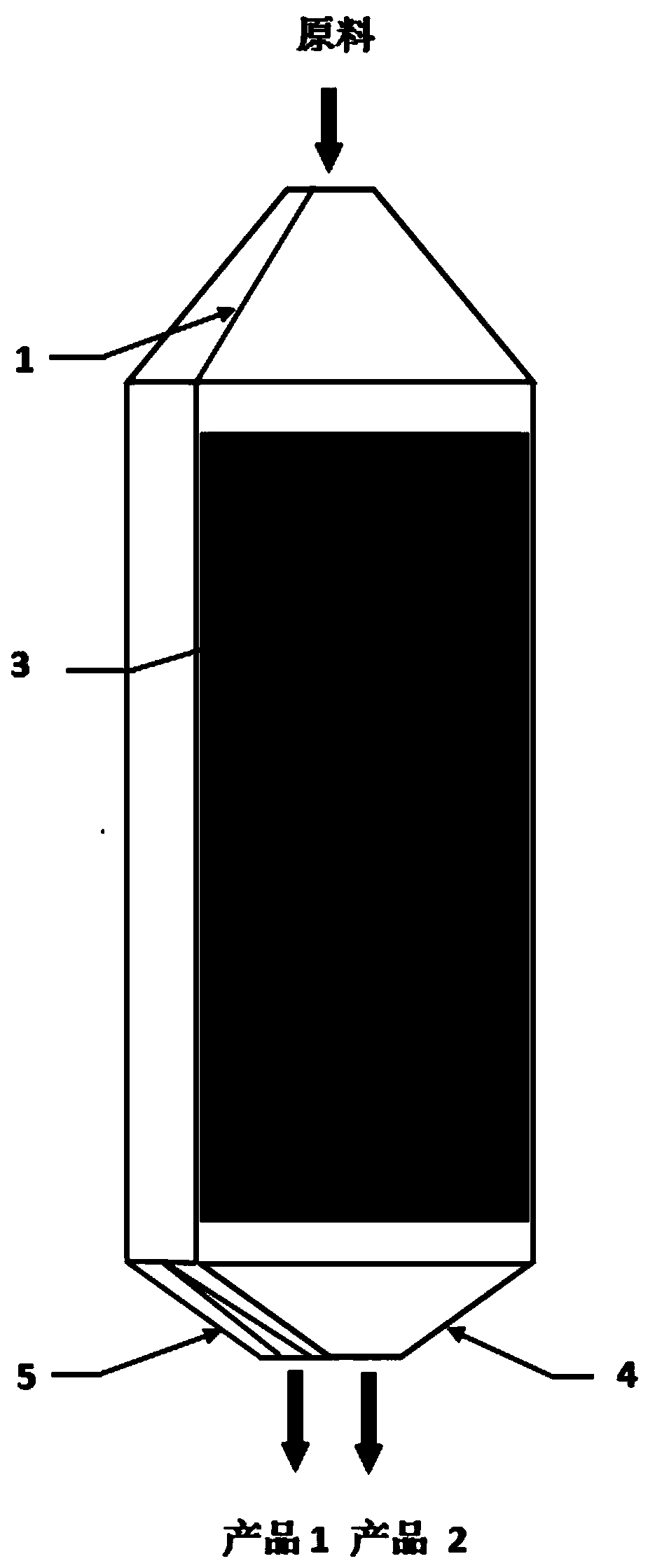

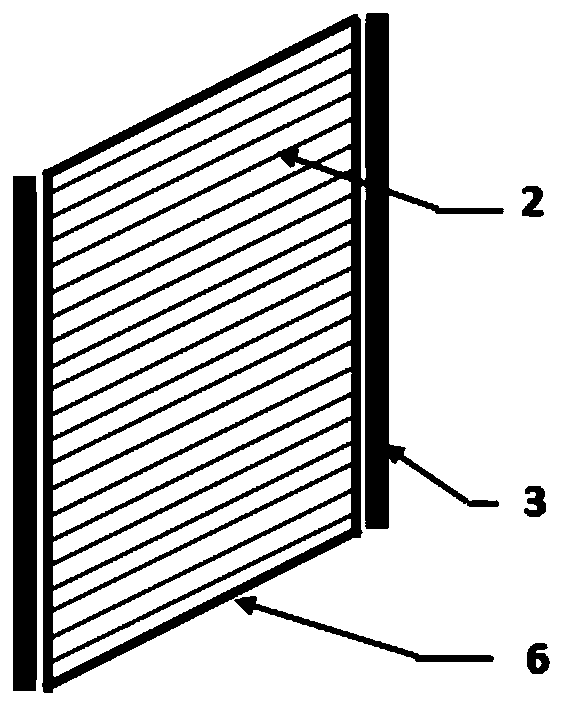

[0034] Such as figure 1 and figure 2 , a triboelectric separator filled with filler friction plates, comprising an electrostatic separation chamber 6, the electrostatic separation chamber 6 is a cuboid four-sided cavity made of insulating material, and the electrostatic separation chamber 6 is along its length A metal electrode plate 3 is arranged on the two opposite sides in the axial direction, and the two metal electrode plates 3 are respectively connected to the high-voltage DC power supply or the earth through wires, which can generate a uniform high-voltage electrostatic field in the electrostatic separation chamber 6 , the strength of the high-voltage electrostatic field is adjustable from 0-30Kv / cm; several packing friction plates 2 are installed inside the electrostatic separation chamber 6, and several packing friction plates 2 are parallel to the long axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com