Multifunctional gap pipeline controlled cryoablation system

A gas pipeline and multi-functional technology, applied in pipeline systems, gas/liquid distribution and storage, conduits, etc., can solve problems such as complex operation and single function, and achieve the effect of improving safety, improving efficiency, and avoiding manual adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

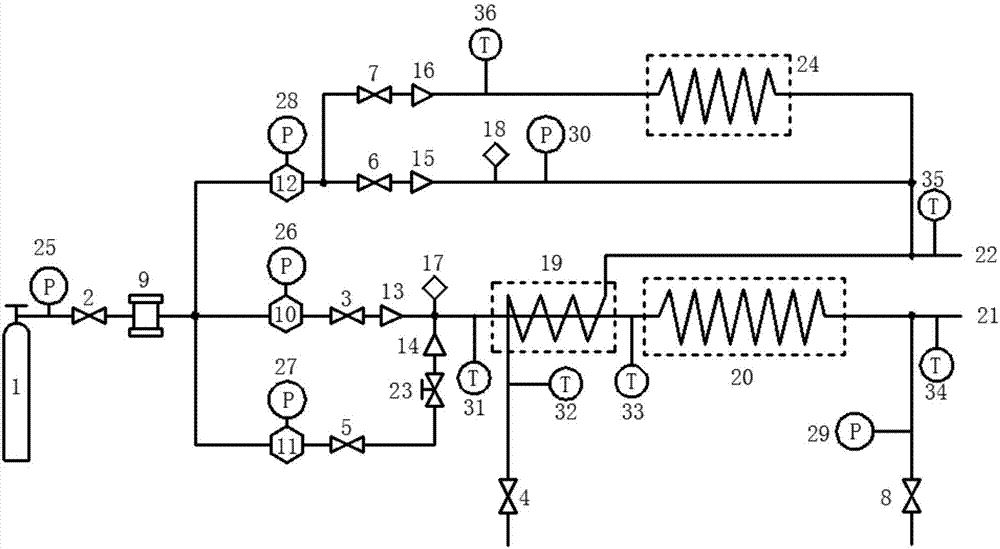

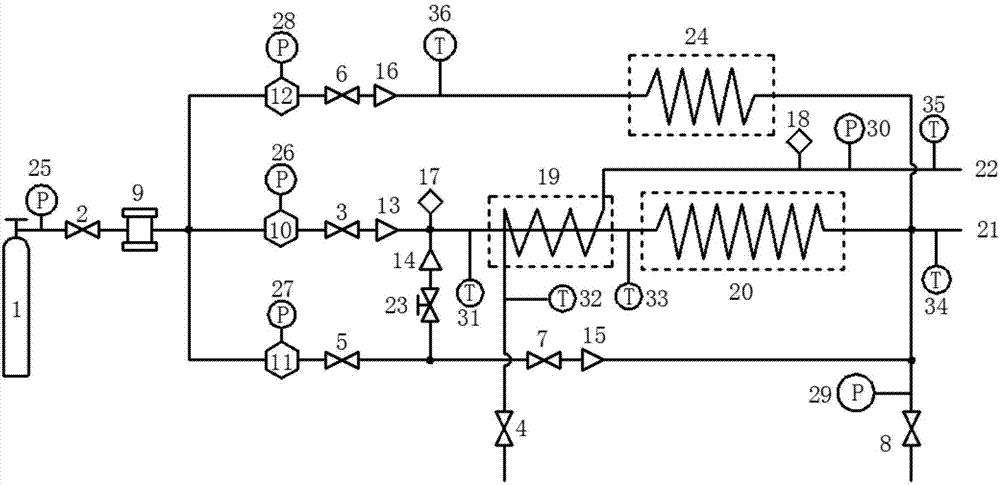

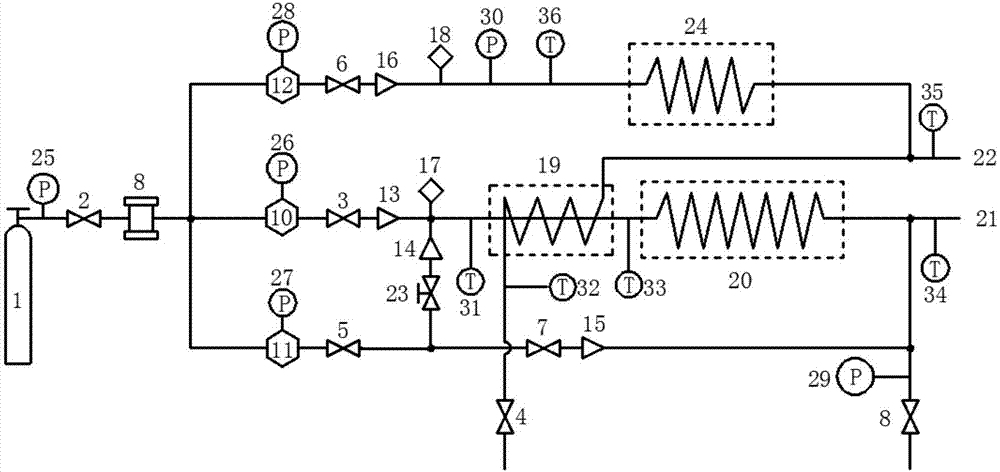

[0034] An example of the use of the cryogenic stage freezing function is as follows: the pressure reducing valve 10 is set to an outlet pressure of 1500 psi, when the freezing function is turned on, the first to third solenoid valves 2, 3, and 4 are opened, and the gas enters from the cryogenic stage freezing pipeline. The excess cooling capacity of the return air is recovered by the primary pre-cooling of the heat exchanger 19 through the return air, and then enters the low-temperature stage heat exchanger 20 (such as the evaporator of the self-cascade refrigeration system) for further pre-cooling to a lower temperature, low temperature The gas enters the cryoablation needle from the air inlet 21, reaches the needle through the throttling effect of the capillary to reach a temperature lower than that of the low-temperature heat exchanger 20, and the cold energy released at the needle is absorbed by the tumor or other diseased tissues, and there is still excess The cooling capa...

Embodiment 2

[0036] An example of the gas-saving / power-adjusted freezing function is as follows: Gas-saving mode: the second decompression valve 11 is set to an outlet pressure of 1200 psi, and the freezing is first turned on, and the process is as in Example 1. After the temperature reaches the lowest temperature (such as -150°C) and the primary precooling of the heat exchanger is sufficient for the return air (such as the thermometer 33 reaches -70°C), close the second solenoid valve 3 and open the fourth solenoid valve 5 and the flow rate at the same time. Controller 23 (full open), thus the working pressure of the system is reduced to 1200psi, and the gas flow rate of the system is reduced, but the temperature of the needle can still maintain the lowest temperature. Gas consumption of cylinder 1.

[0037] Power adjustment mode: if it is necessary to slow down the growth rate of the ice ball or stop the growth of the ice ball during the operation, the flow control value of the flow cont...

Embodiment 3

[0039] Examples of rewarming\freezing without precooling are as follows: figure 1 As shown, in the rewarming process, the third pressure reducing valve 12 is set to 300 psi. After freezing, close the first to fourth electromagnetic valves 2, 3, 4, 5 and flow controller 23, and when the rewarming function is turned on, open the first, fifth, and seventh electromagnetic valves 2, 6, 8, and the gas does not pass through any The pre-cooling directly enters the return air line of the cryoablation needle from the air return port 22, and enters the capillary after reaching the needle. This process has no throttling effect. With the heating module in the cryoablation needle, a good rewarming effect can be achieved. The gas returns from the air inlet 21, and then is discharged to the atmosphere through the seventh solenoid valve 8. During the rewarming process, the pressure gauges 30 and 29 respectively monitor the pressure of the inlet and outlet air in real time. When the inlet pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com