hub motor drive wheel

A technology of in-wheel motor and driving wheel, applied in electric components, electromechanical devices, electrical components, etc., can solve problems such as motor burnout, and achieve the effect of increasing electromagnetic force, increasing volume, increasing power density and torque density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

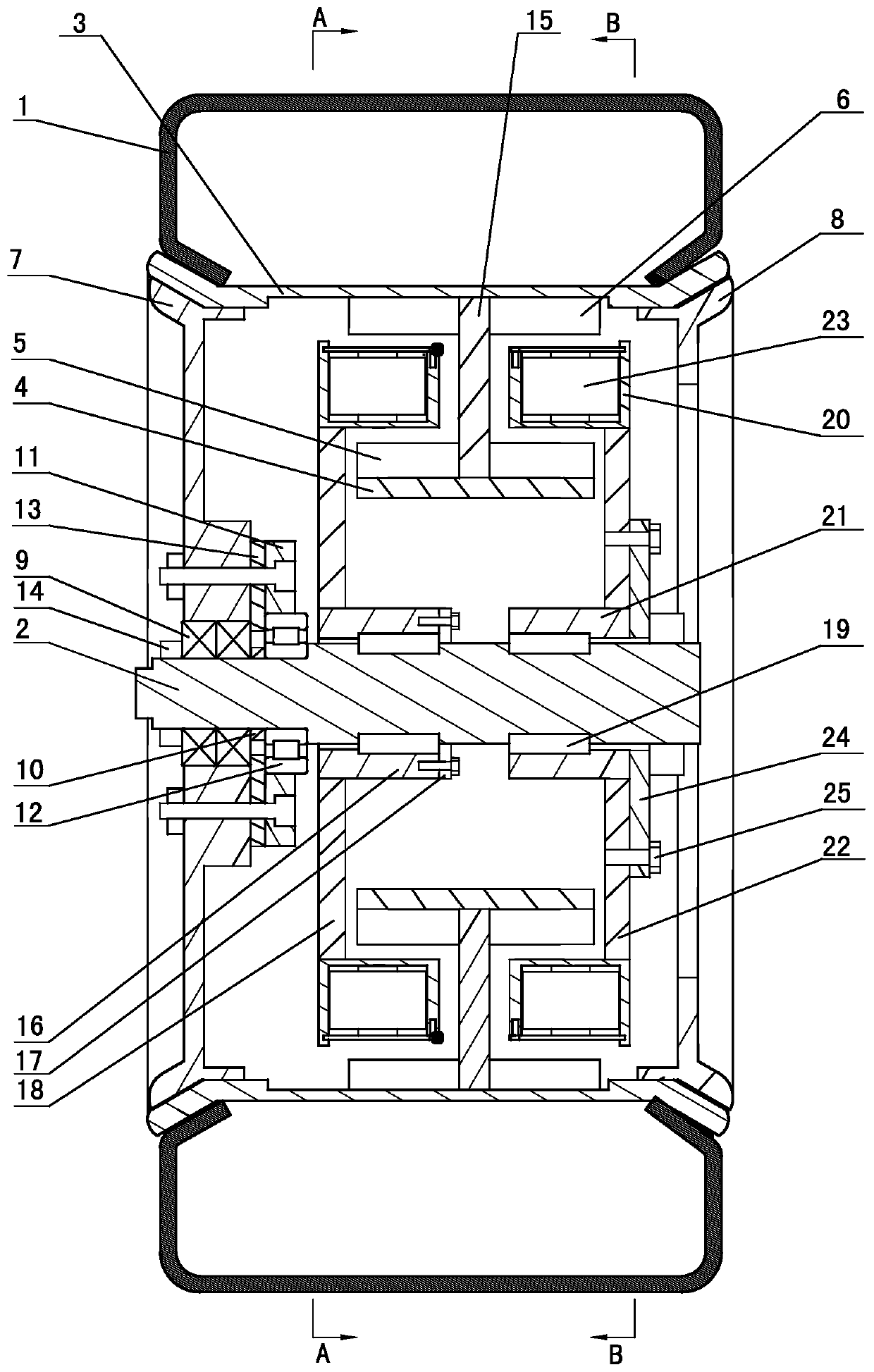

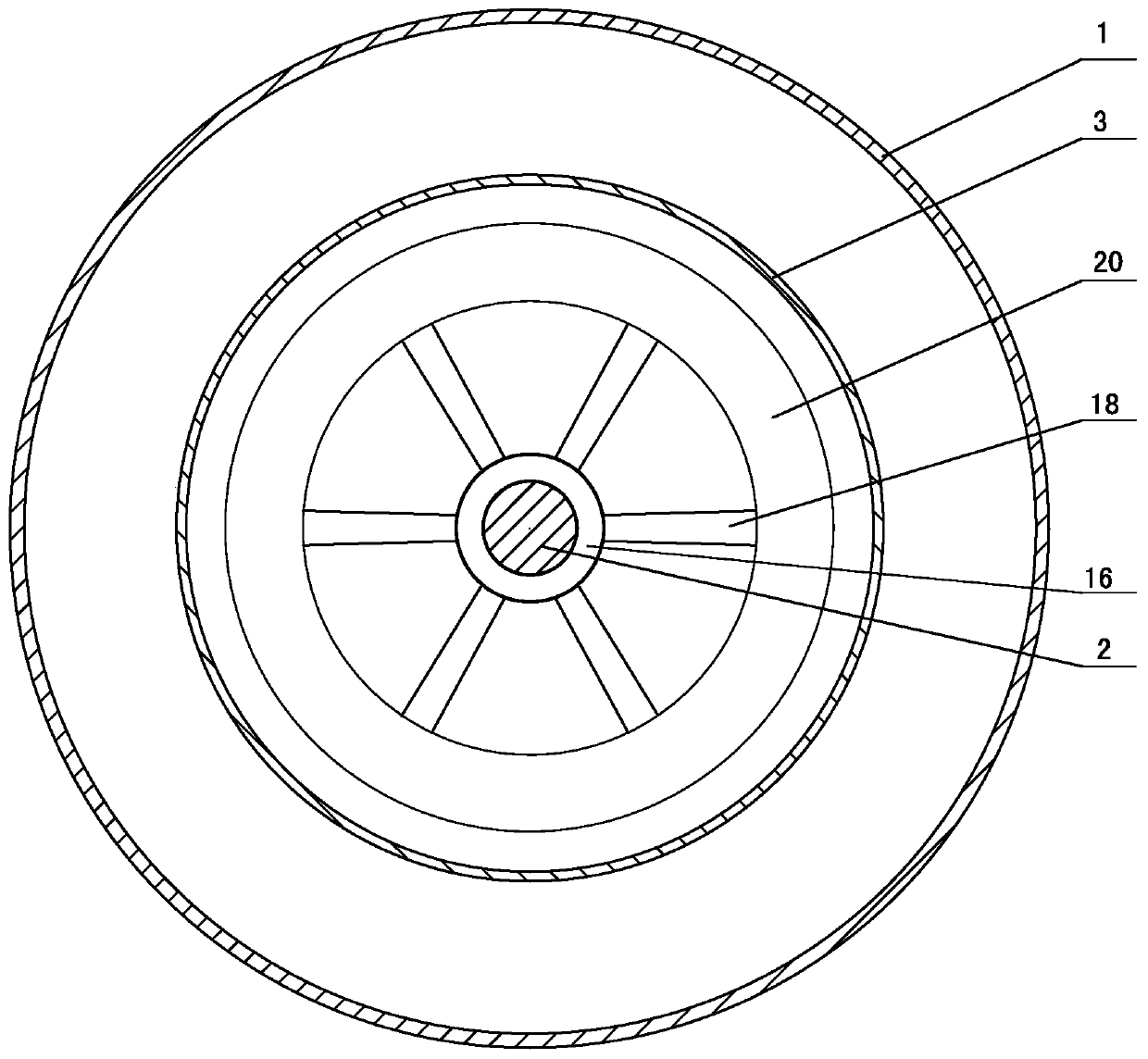

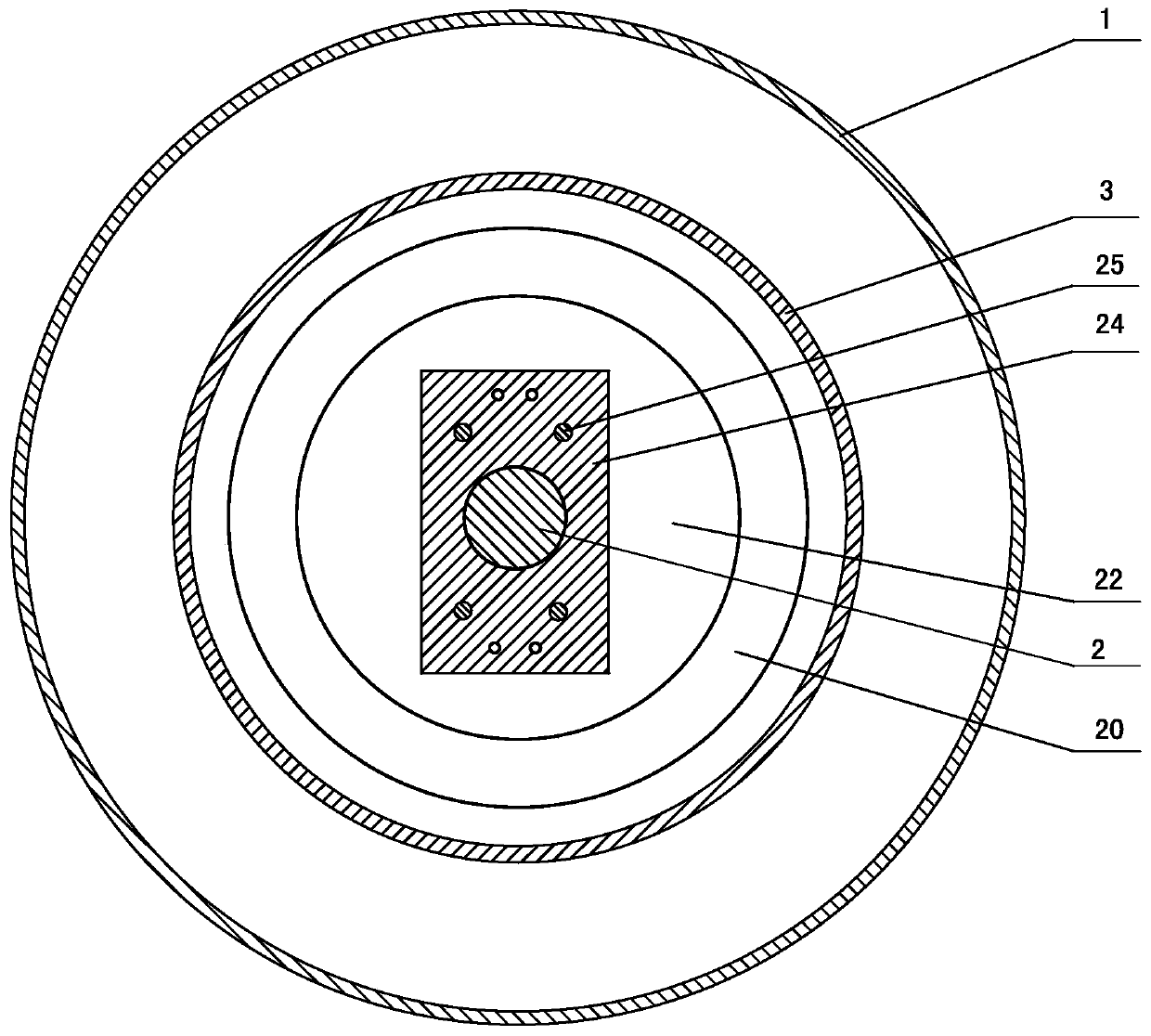

[0021] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments. exist Figure 1-3 In the example shown:

[0022] The rotor assembly includes a cylindrical middle casing 3, a cylindrical base 4, 2 sets of inner ring permanent magnets 5, 2 sets of outer ring permanent magnets 6, and a left casing 7 and a right casing separated on both sides of the middle casing 3. body 8, the middle housing 3 adopts a structure with both sides thick and the middle thin. Among them: the left housing 7 and the right housing 8 are both ring-shaped, set on both ends of the stator shaft 2, the inner end of the left housing 7 is supported on the stator shaft 2 through two angular contact ball bearings 9, the left housing The right side of the body 7 is provided with a first positioning ring 10 and a limit ring 11 in sequence, wherein the inner end of the limit ring 11 is supported on the stator shaft 2 through a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com