Cooling structure for screw air compressor

A cooling structure and air compressor technology, applied in cooling/ventilation devices, electromechanical devices, mechanical equipment, etc., can solve the problems of high investment cost and large floor space, reduce investment cost, occupy small space and save cooling The effect of the fan casing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

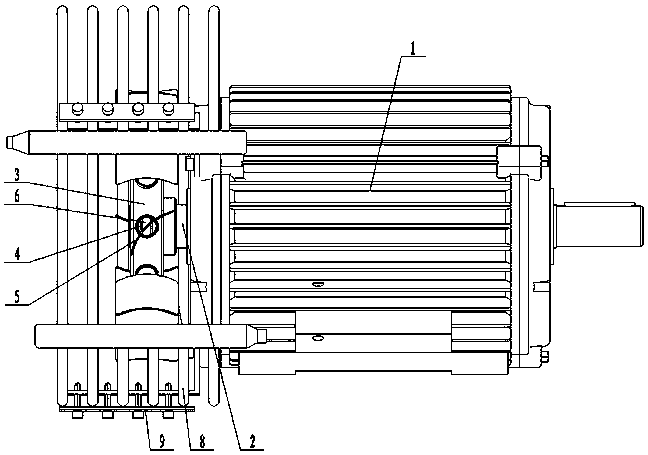

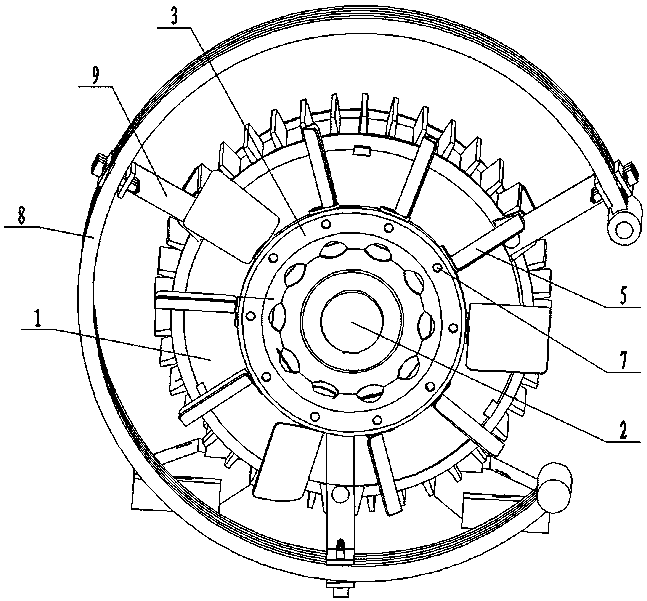

[0010] Such as figure 1 , figure 2 As shown, the cooling structure of the screw air compressor includes: the main body of the screw air compressor motor 1, in which the motor main body 1 of the screw air compressor is provided with a biaxial extension motor shaft 2, and one end of the biaxial extension motor shaft 2 Extend the screw air compressor motor body 1 to connect with the screw air compressor, and the other end of the biaxial extension motor shaft 2 protrudes from the screw air compressor motor body 1 to connect with the flange 3, and the flange A number of fixing holes 4 are uniformly arranged on the outer side of the disc 3, and the fan blades 5 are respectively arranged in the fixing holes 4 through the adjusting blocks 6 that cooperate with the fixing holes 4, and the adjusting blocks 6 are connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com