Electrified railway digital traction substation automation system

A technology for traction substations and automation systems, applied in electrical components, circuit devices, etc., can solve the problems of poor safety performance, low operation efficiency, and the control function of substations cannot be optimized, so as to improve the selectivity and speed. reliability, accurate and reliable fault location, and shortened fault response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

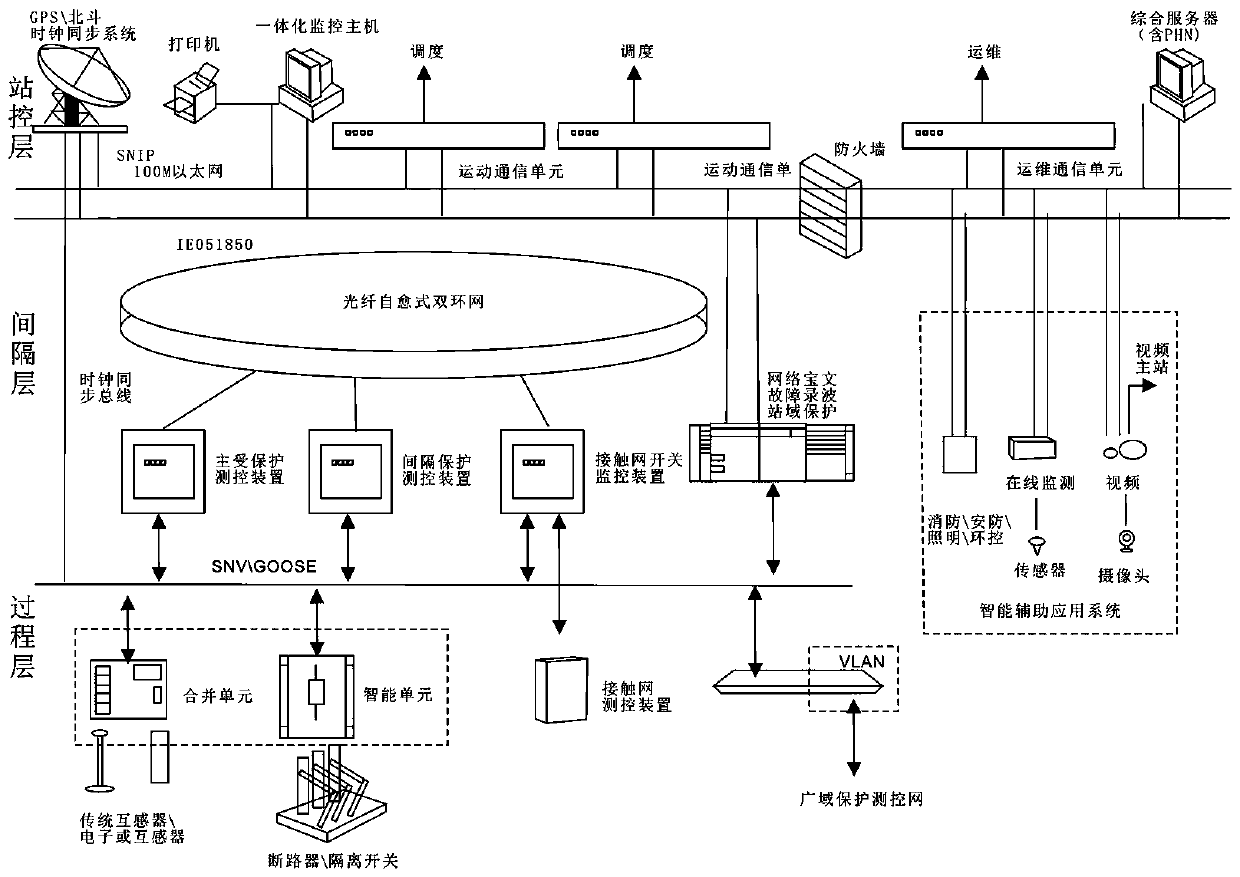

[0027] The automation system of digitized traction substation for electrified railway consists of three layers of equipment: station control layer, interval layer and process layer. Simply put, it is "three layers and two networks", such as figure 1 shown. The system consists of intelligent substation monitoring software, intelligent network message recording and analysis system, clock synchronization unit, telecontrol communication unit, interval layer series protection measurement and control devices, process layer series intelligent components, etc. The intelligent primary equipment can use electronic transformers , smart switches, smart transformers, and traditional primary equipment can also be used to realize the intelligence of primary equipment by configuring intelligent components.

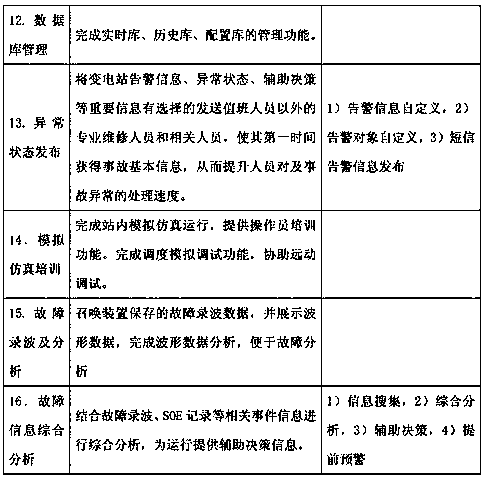

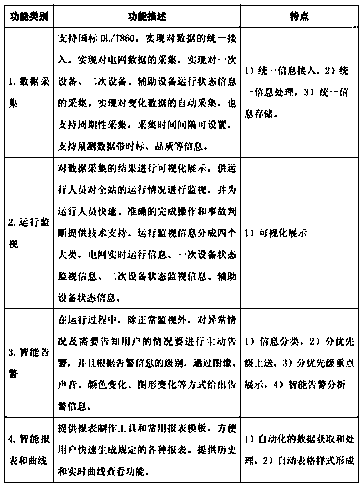

[0028] Intelligent substation monitoring software includes engineer station subsystem, protection monitoring subsystem, drawing maintenance subsystem, data maintenance subsystem and repor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com