Processing device for sunshade screen in overhead power transmission line lead span

A technology for overhead transmission lines and processing devices, applied in the direction of overhead lines/cable equipment, etc., which can solve the problems of high safety risks in live-line work, increased difficulty in dragging, and difficult processing, etc., and achieves a simple and effective processing method and saves manpower and material resources , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

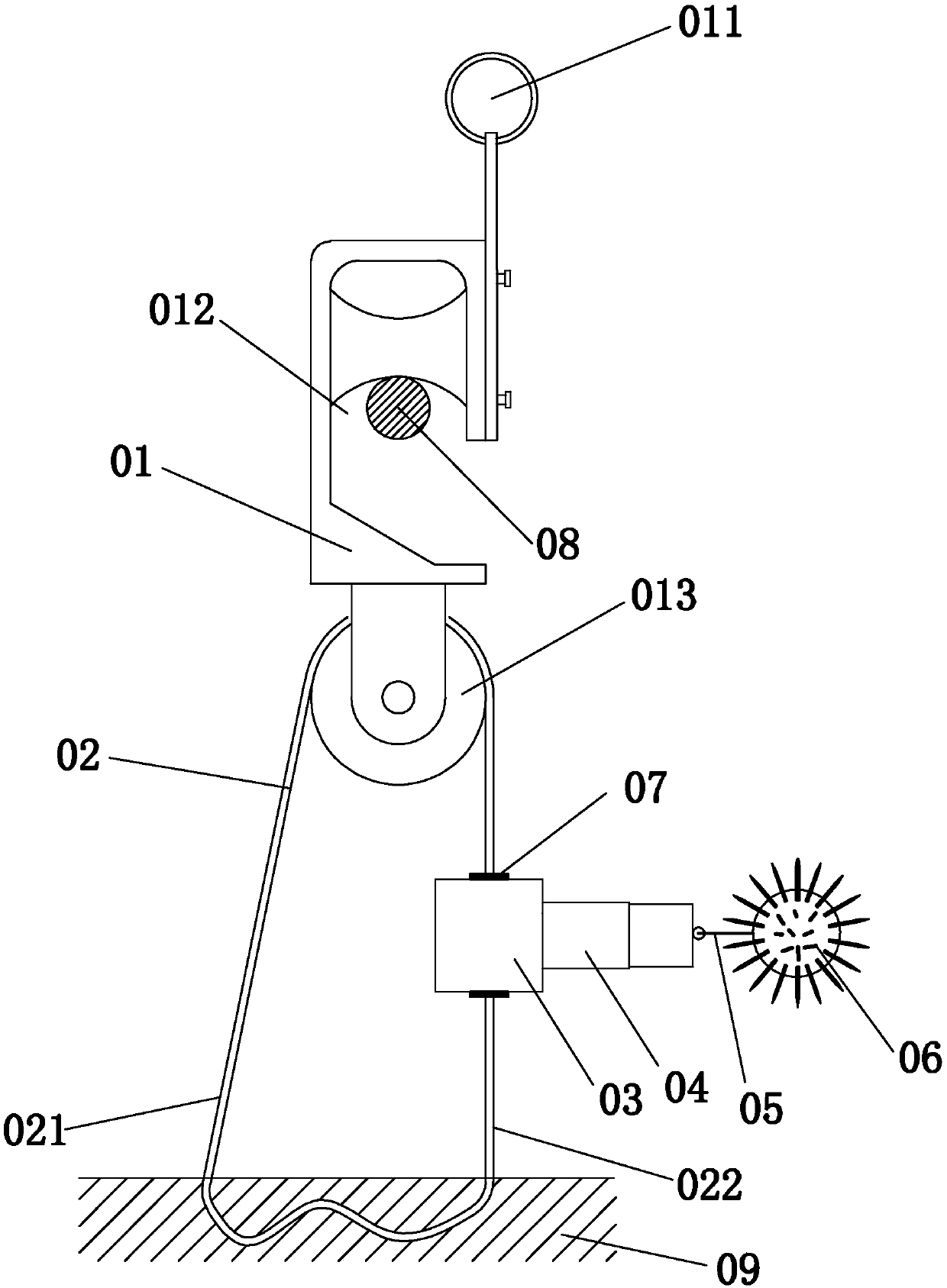

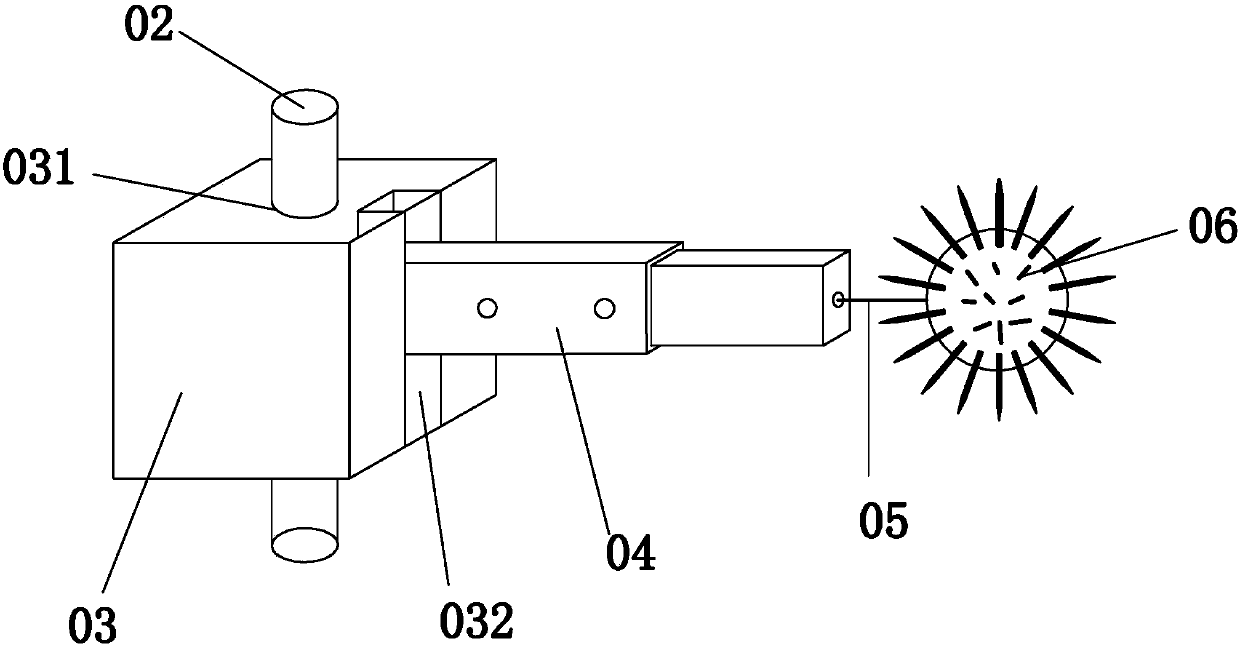

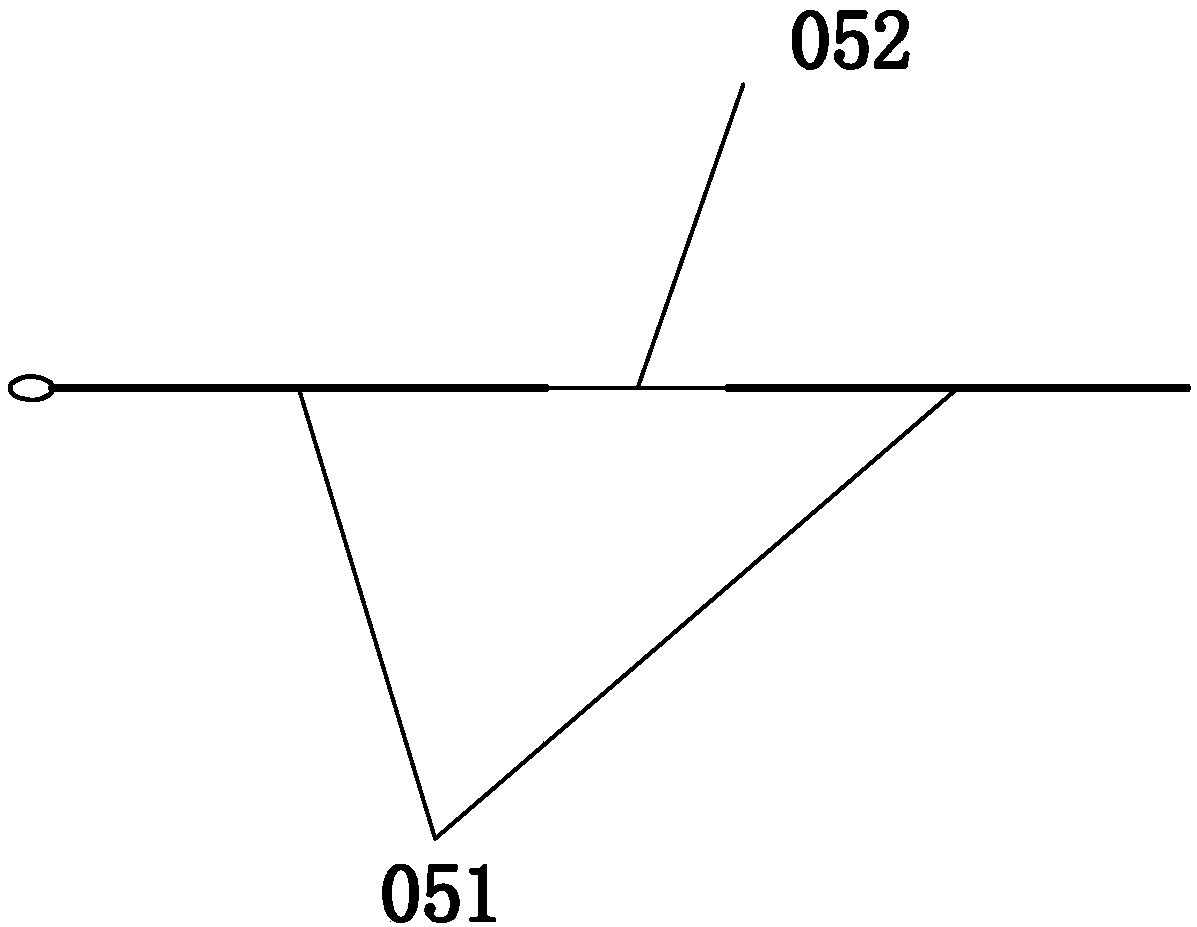

[0023] Example 1: as figure 1 , 2 As shown in the figure, a processing device for a sunshade net in a guide (ground) wire block of an overhead transmission line includes an insulating block removal pulley 01 and an insulating endless rope 02. The insulating endless rope is sleeved with a sliding block 03, and the sliding block is rotatably connected with a The operating arm 04, one end of the operating arm away from the slider is connected to the acupuncture ball 06 through a restraining rope 05. The slider is in the shape of a hexahedron, the middle of the slider is provided with a cylindrical through hole 031 parallel to the axis of the slider, the insulating infinite rope runs through the through hole, and one side of the slider is provided with a rectangular rotation slot 032 parallel to the axis of the slider. The arm is movably connected in the rotating groove, and the upper and lower ends of the slider are fixedly connected with the insulating infinite rope through the...

Embodiment 2

[0026] Embodiment 2: The structure of this embodiment is basically the same as that of Embodiment 1, and the difference is that, such as Figure 8 As shown, the acupuncture ball is composed of a sphere 061 and a crochet needle 063. Several evenly arranged crochet needles are arranged on the outer surface of the sphere. The free end of the crochet needle is in the shape of a semi-circular arc, and the end of the crochet needle is a sharp cone, suitable for piercing with only steel needles. If the sunshade net is not easy to stick firmly with the sunshade net, the sunshade net can be pierced by a crochet needle and then hooked firmly to the sunshade net, so that the ground staff can smoothly pull the sunshade net off.

Embodiment 3

[0027] Embodiment 3: The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that, as Figure 9 As shown, the acupuncture ball is composed of a sphere 061, a steel needle 062 and a crochet needle 063. Several alternately arranged steel needles and crochet needles are arranged on the outer surface of the sphere. The free ends of the crochet needles are semi-circular arcs, and the ends of the steel needles and crochet needles are sharp cones. . On the one hand, the steel needle can effectively pierce the sunshade net, on the other hand, the crochet needle can pierce the sunshade net and then firmly hook the sunshade net, which increases the firmness of the combination of the acupuncture ball and the sunshade net. Operation is more convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com