Method of manufacturing demand and device capability normalization modeling facing cloud manufacturing

A technology of equipment capability and modeling method, applied in manufacturing computing systems, office automation, data processing applications, etc., can solve problems such as inability to obtain economic benefits, restrict the promotion and development of networked manufacturing, and lack of perfect operation service models, etc., to achieve The effect of improving efficiency and capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

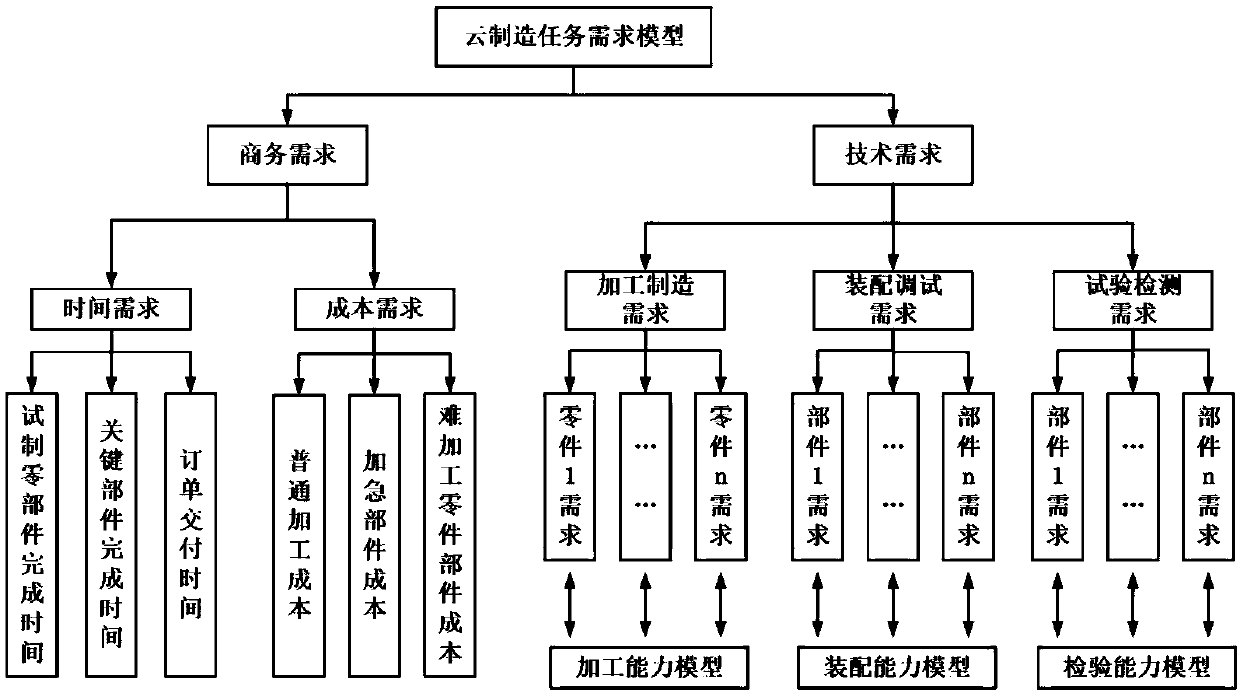

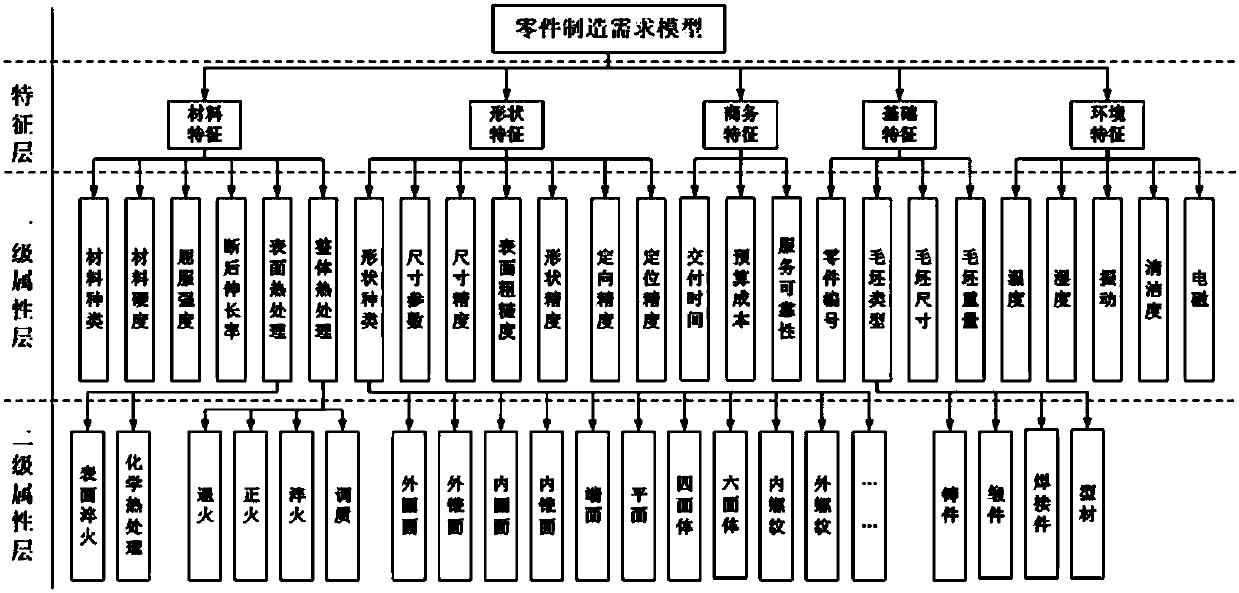

[0056] The cloud manufacturing-oriented manufacturing demand and equipment capability normalization modeling method of this embodiment includes the following steps:

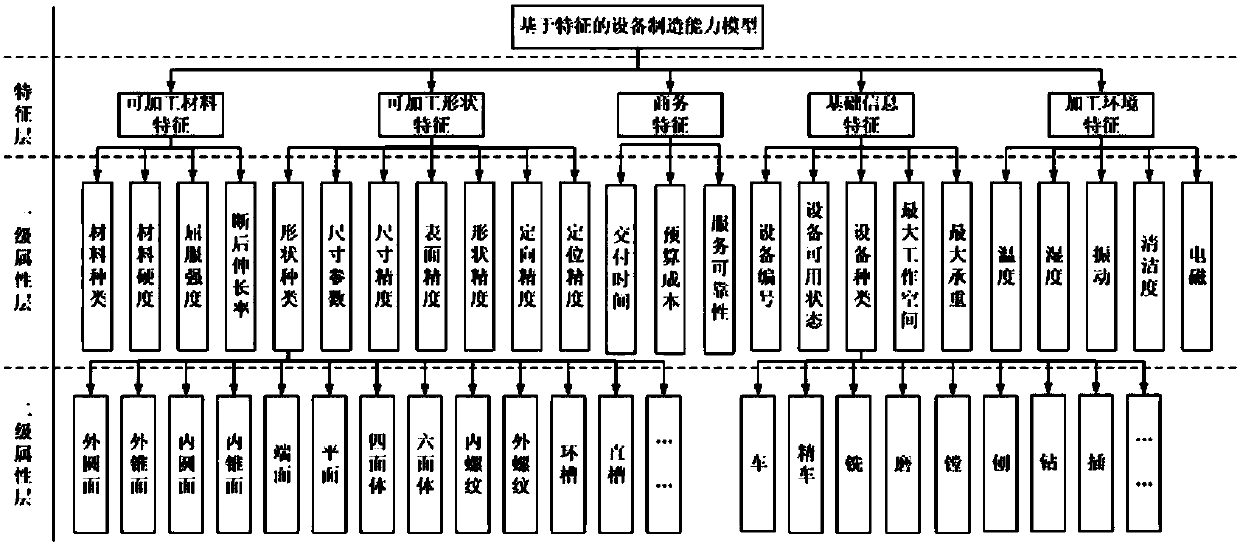

[0057] Step 1. Equipment capability modeling: Equipment capability modeling refers to the description and evaluation of the manufacturing capability of the equipment resource group. For manufacturing enterprises, it refers to the production elements required in the process of parts processing, including production process resources such as equipment, cutting tools, measuring tools, fixtures, and auxiliary tools, among which the most important is equipment resources. This embodiment constructs a feature-based equipmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com