A device and method for quickly measuring the heat capacity of thin film materials

A thin-film material and fast technology, applied in the field of thermal measurement, can solve problems such as difficult measurement of thin-film thermal properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

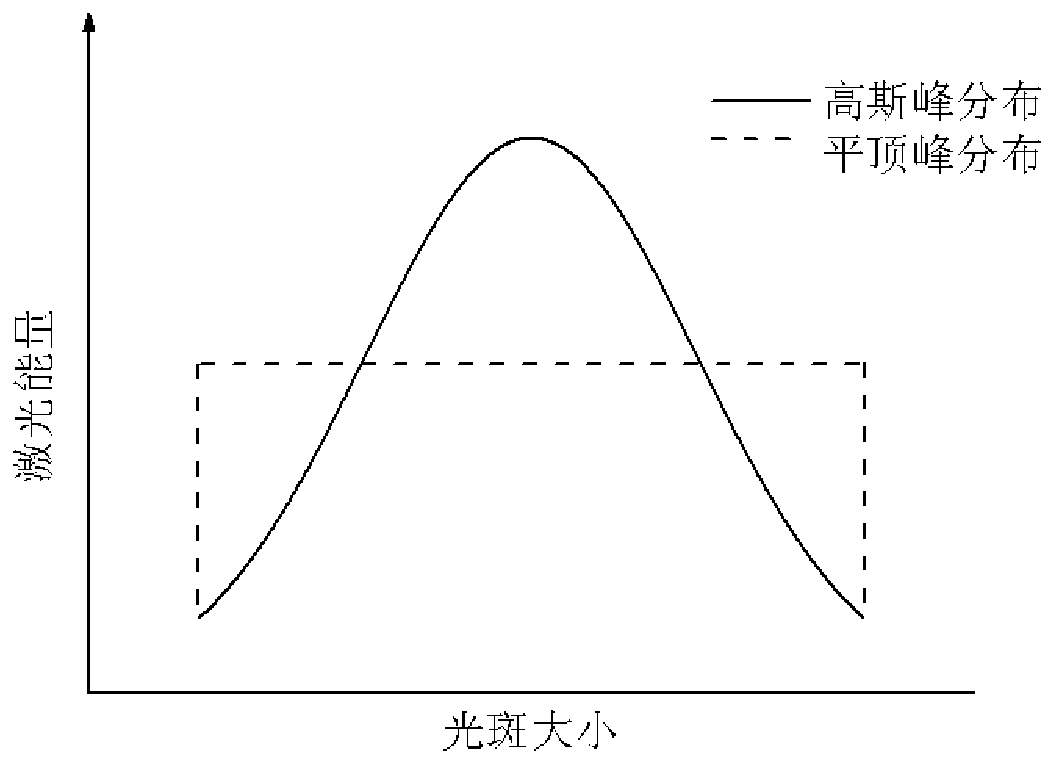

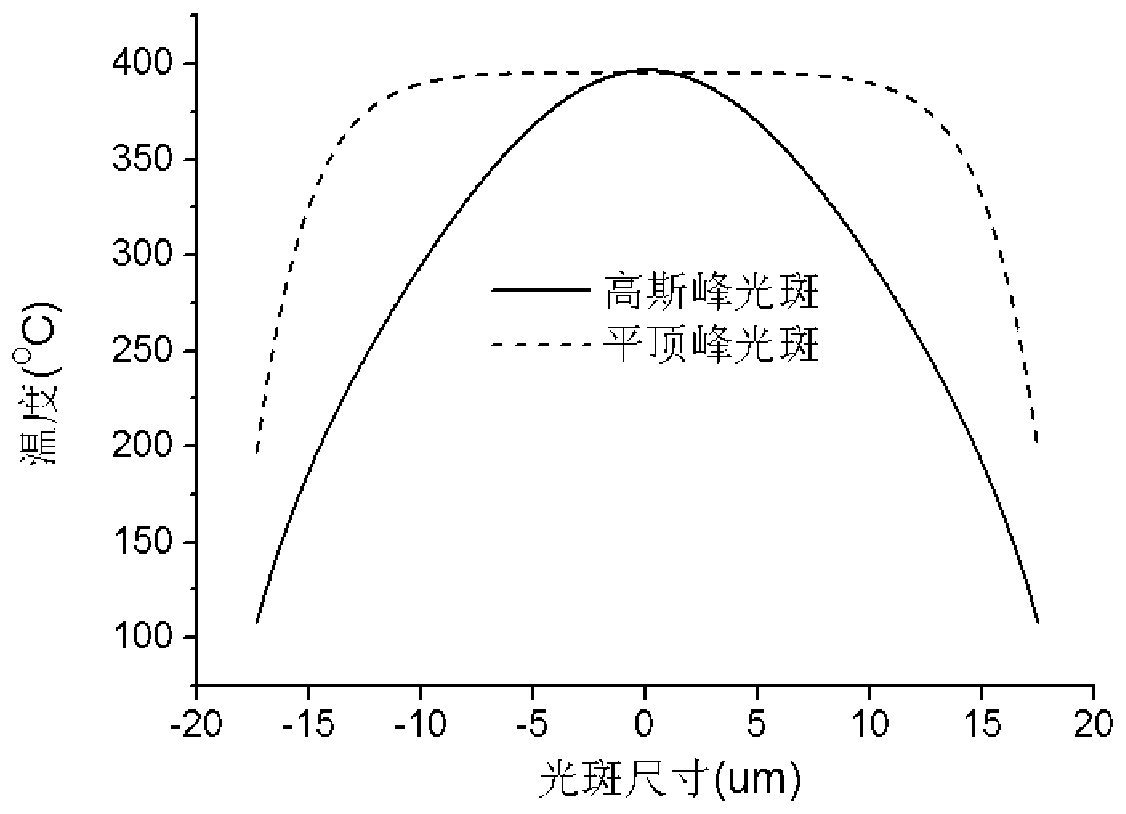

[0100] The device for rapidly measuring the heat capacity of the thin film material in this embodiment is as follows: Figure 5 shown, Figure 5 The measurement process of the heat capacity of the material is shown. The computer control center 101 is used to send a start signal to the clock synchronizer 102 to ensure that the start of the laser 103 and the fast thermometer of 104 are coordinated and linked, and the laser emitted by the laser 103 passes through the beam expander. After 105, the laser light intensity is reduced, and after the laser passes through the spatial light shaper, the Gaussian spatial distribution of the laser energy is as follows: figure 2Solid line, shaped as a flat-topped peak distribution as in figure 2 dotted line. The laser light emitted from the spatial light shaper 106 passes through the focusing mirror 107 and then irradiates the surface of the sample. The rapid pyrometer 104 captures the sample surface temperature at a certain point in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com