Method for measuring dynamic damage degree of rock in confining pressure condition

A dynamic, rock-based technology, applied in the direction of using stable tension/pressure to test material strength, measuring device, strength characteristics, etc., to achieve the effect of convenient operation, solving actual engineering needs, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

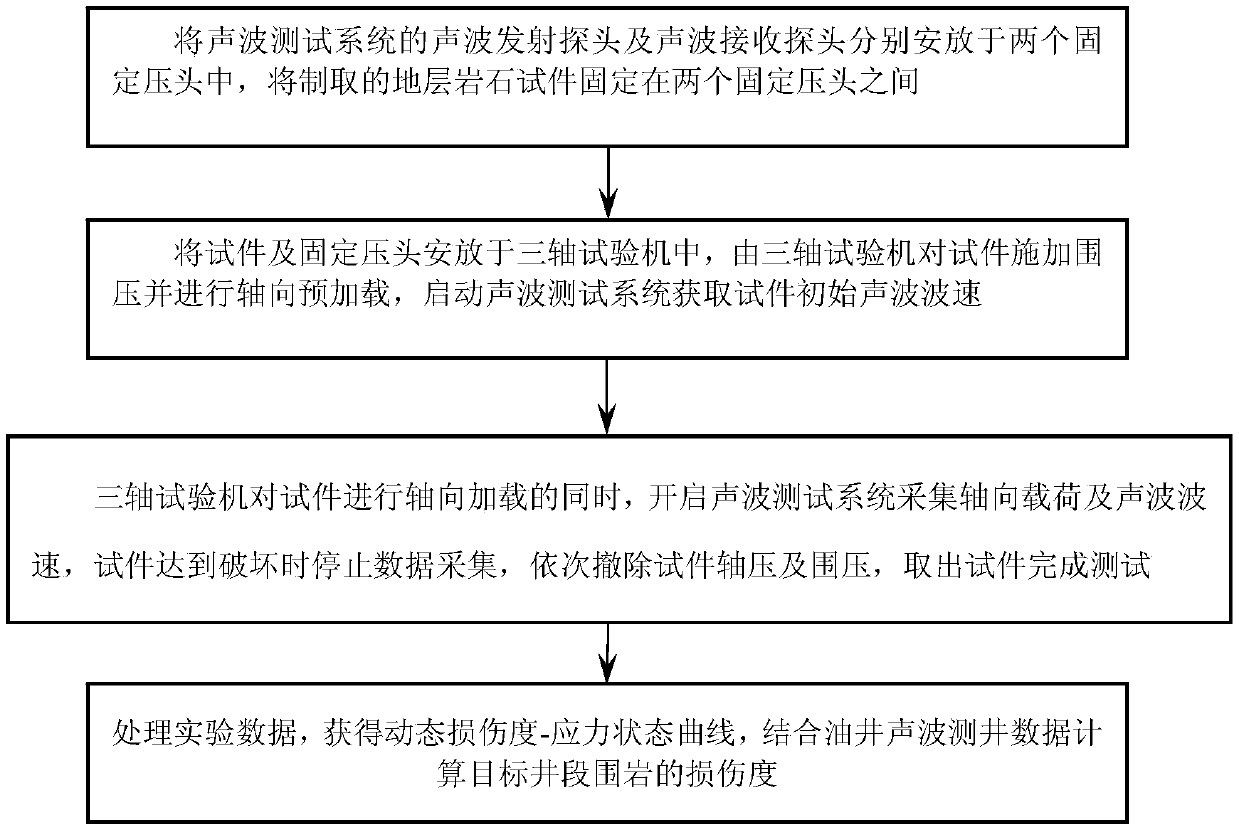

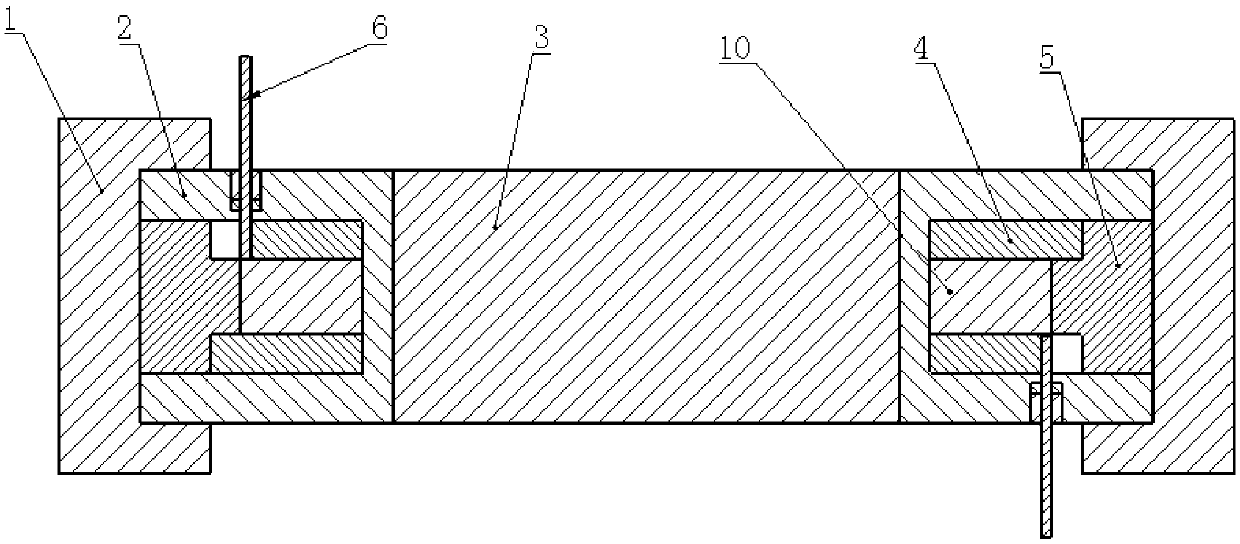

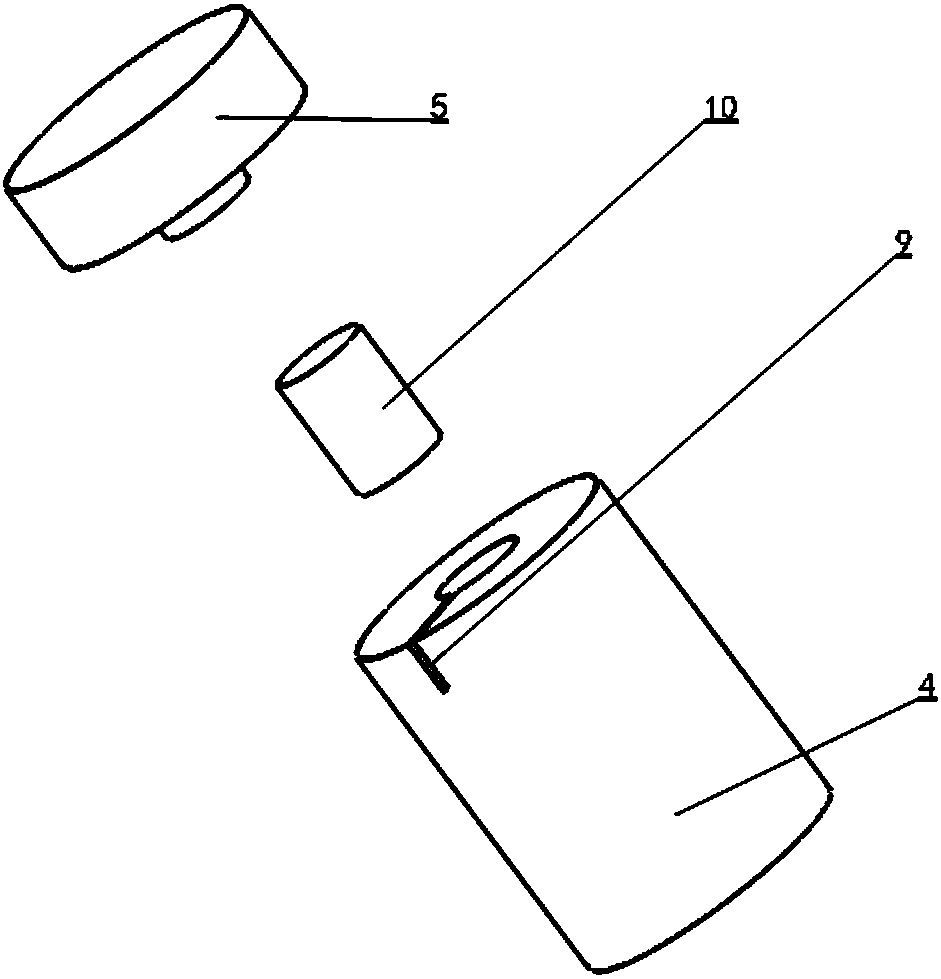

[0032] The present invention proposes a method for measuring the dynamic damage degree of rock under confining pressure conditions, comprising the following steps: 1) placing the acoustic wave transmitting probe and the acoustic wave receiving probe of the acoustic wave testing system in two fixed indenters respectively, and placing the prepared stratum The rock specimen is fixed between two fixed indenters; 2) The specimen and the fixed indenter are placed in the triaxial testing machine, and the confining pressure is applied to the specimen by the triaxial testing machine and the axial preload is carried out, and the sound wave is started. The test system obtains the initial acoustic wave velocity of the specimen; 3) While the triaxial testing machine is axially loading the specimen, the acoustic wave testing system is turned on to collect the axial load and acoustic wave velocity, and the data collection is stopped when the specimen reaches failure, and the specimens are remo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com