Plate reaction type automobile brake test device

A technology for automobile braking and inspection devices, which is used in measuring devices, vehicle testing, force/torque/work measuring instruments, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

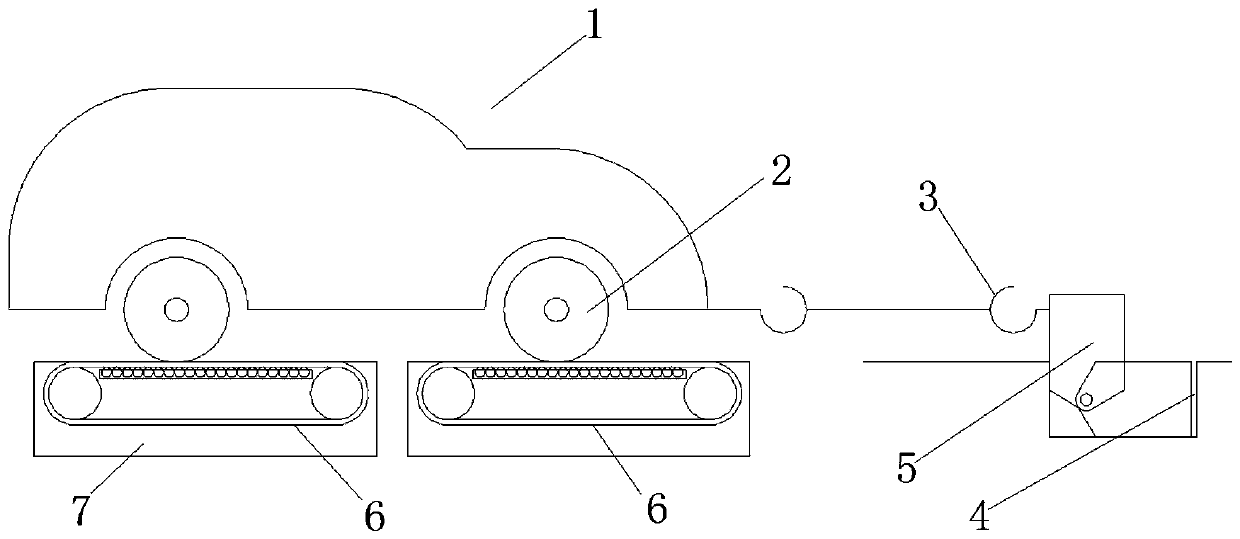

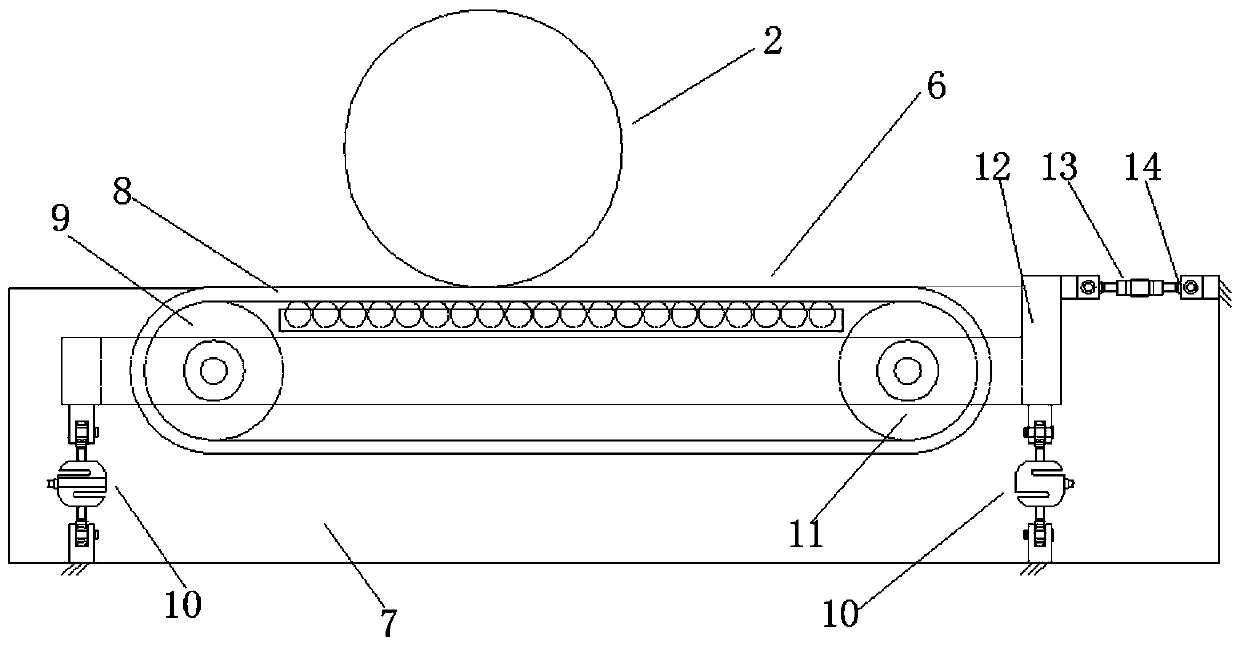

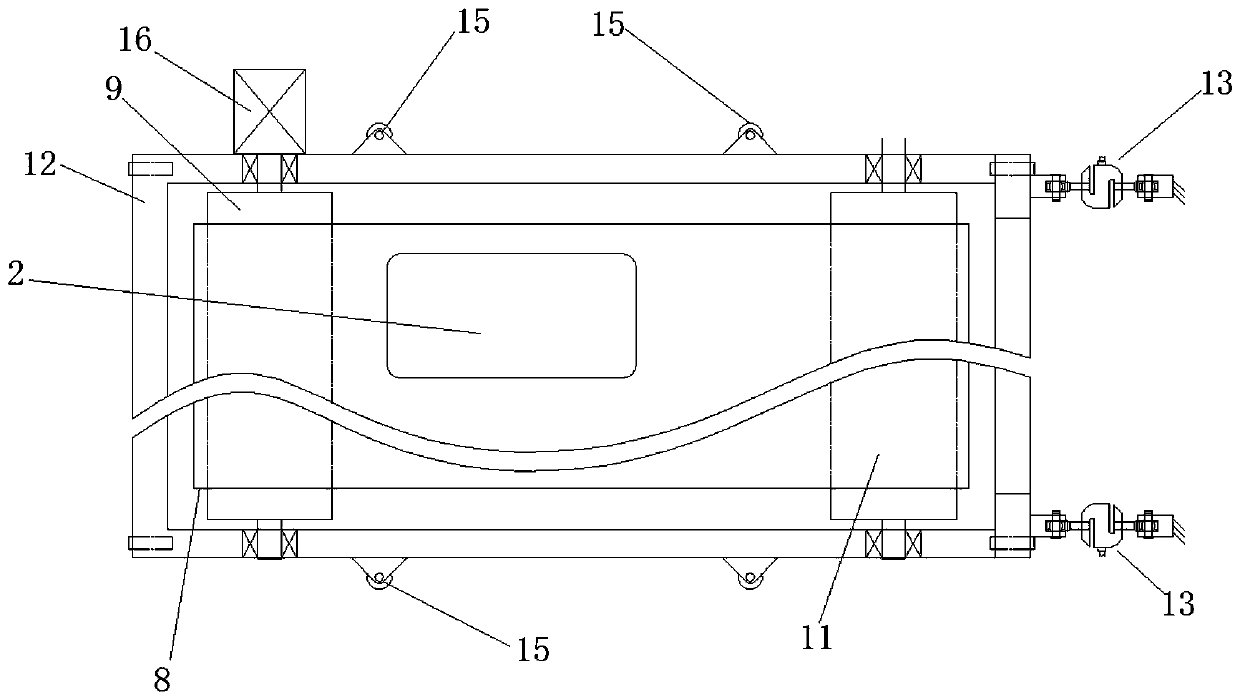

[0023] Embodiment 1 of the plate reaction force type automobile brake inspection device is as Figure 1~5 As shown: it includes two pairs of vehicle braking force testing units arranged front and rear, and each pair of vehicle braking force testing units includes two vehicle braking force testing units 6 arranged left and right. The flat-plate reaction force vehicle brake testing device has accommodating grooves 7, and each vehicle braking force testing unit 6 is respectively placed in the corresponding accommodating grooves 7. The plate reaction force type automobile brake inspection device also includes an automobile fixing device for fixing the automobile. In this embodiment, the automobile fixing device is a force applying mechanism for applying a forward and reverse pulling force to the automobile. The automobile fixing device includes a hinged The hinged frame 5 in the sinker 4 on the front side of the vehicle braking force test unit, the hinged frame 5 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com