Unidirectional shearing model case for vibration table tests

A shear model box and shaking table test technology, which is applied in the field of civil engineering, can solve problems such as less consideration of the influence of lateral earth pressure, shedding of adjacent frames, and the existence of boundary effects, so as to avoid vibration interference, reduce errors, and reduce impacts Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

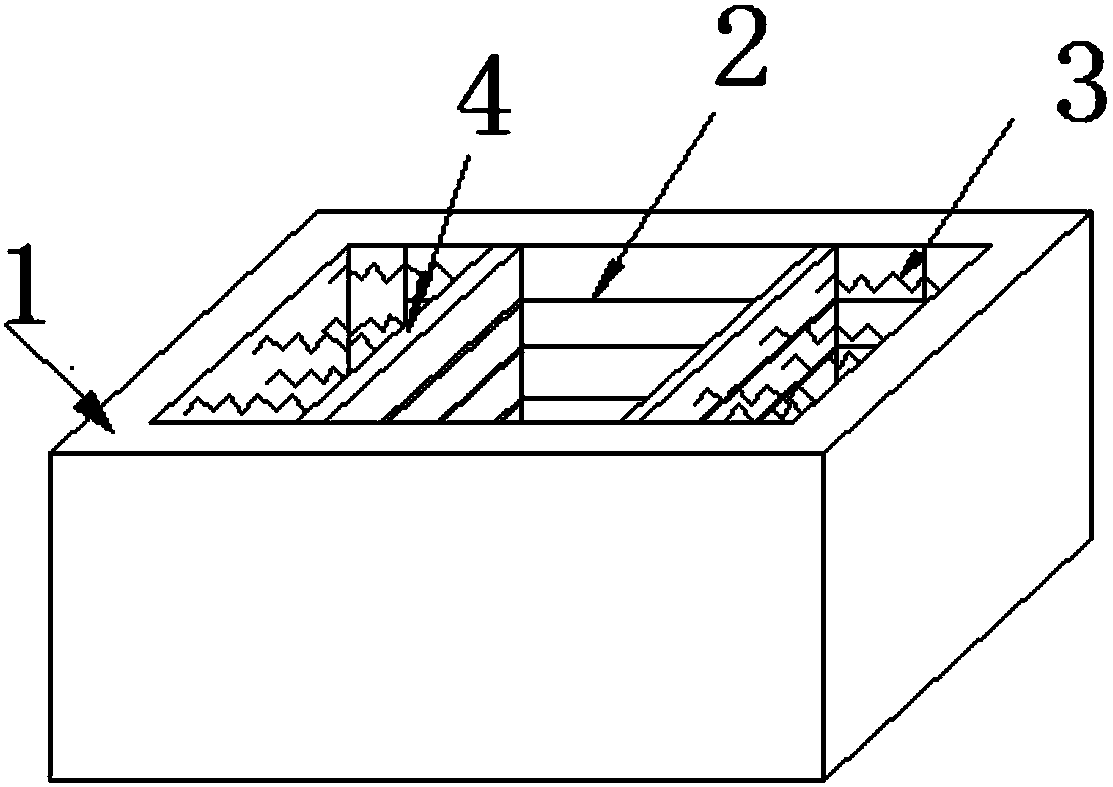

[0020] A kind of unidirectional shear model box used for shaking table test, the peripheral box 1 is used as the peripheral structure, and there are several longitudinal chute 2 on the inside of the longitudinal plate of the peripheral box 1, as the movement of the layered side plate 4 guide.

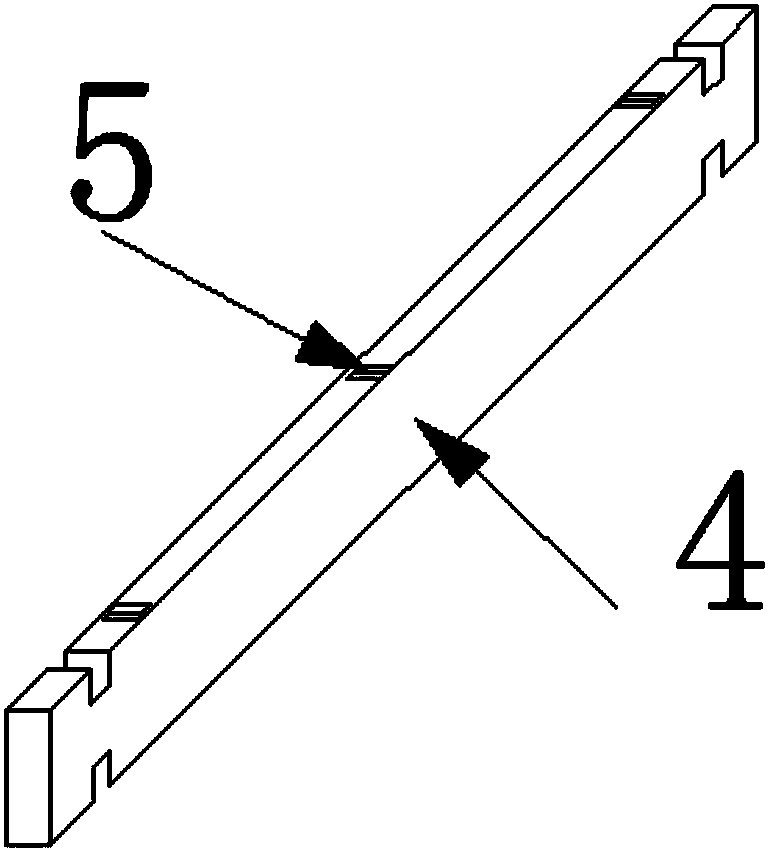

[0021] The structure of longitudinal chute 2 is as follows image 3 As shown, the two ends of the layered side plate 4 are embedded in the longitudinal chute 2, and the bead row is embedded between the end and the peripheral box 1, so that the layered side plate 4 can slide freely in the longitudinal chute 2, reducing the impact of the model box on the soil. interference and impact.

[0022] The layered side panels 4 in the box have a structure such as figure 2 As shown, the two ends are T-shaped, and there must be a cert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com