Vacuum cooling machine body capable of solving food safety and sanitation problem

A vacuum cooler and food safety technology, applied in food preservation, food science, household refrigeration equipment, etc., can solve problems such as unguaranteed, high waterproof and airtightness, threats to food safety and hygiene, etc., to achieve fewer bacterial colonies and avoid bacterial retention Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

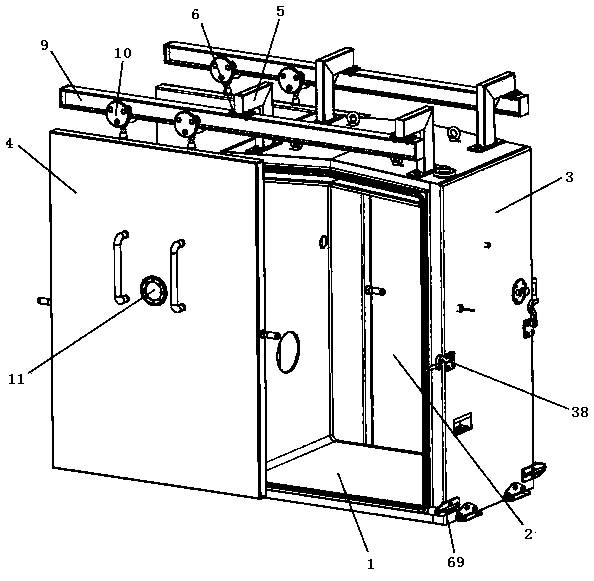

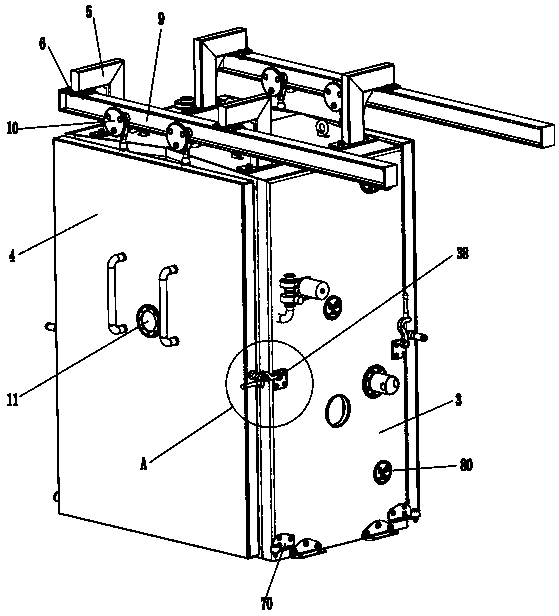

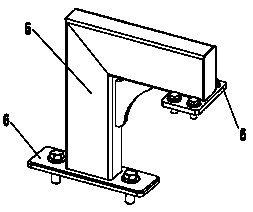

[0077] Such as figure 1 , 2 , 3, a vacuum cooler body that can solve food safety and hygiene problems, including a box body 3 with front and rear feeding and discharging materials 1, 2 and hanging on the box body 3 inlet and outlet ports 1, 2 can be moved along the box body 3 The sealing door 4 that slides left and right is specifically provided with two L-shaped brackets 5 above the inlet and outlet ports 1 and 2 of the casing 3, and a base 6 is provided at both ends of the bracket 5, and a sealing groove is provided on the base 6 for sealing. A sealing ring is provided in the groove, and the other end of the bracket 5 protrudes to the outside of the box body 3, and a guide rail 9 is provided between the protruding ends of the two brackets 5, and the base 6 is respectively connected with the guide rail 9 and the box body 3, and the guide rail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com