Lubricating device for steel wire rope

A lubricating device and steel wire rope technology, which is applied in lubricating oil containers, lubricating parts, engine lubrication, etc., can solve problems such as difficulty in ensuring uniform brushing on the surface of steel wire ropes, heavy operation and maintenance workload, waste of lubricating grease, etc., and achieve good dynamics And static sealing effect, avoid leakage and environmental pollution, effect of long-term high-efficiency sealing function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

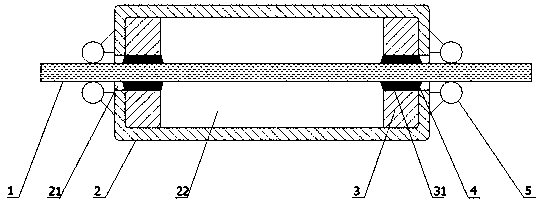

[0026] like figure 1 As shown: a wire rope lubricating device, including a housing 2 and a magnetic sealing device, the housing 2 is provided with an accommodating space 22, and openings 21 are provided at both ends; the magnetic sealing device includes a The sealed magnetic part 3, the sealed magnetic part 3 is provided with a sealed inner hole 31, and the sealed inner hole 31 is provided with a magnetic grease 4,

[0027] Specifically, the magnetic lubricating grease 4 is added into lubricating oil or lubricating grease by adding nano-magnetic powder, so that it can be adsorbed by magnetic objects while providing good lubricity.

[0028] Specifically, the sealing magnetic member 3 is a permanent magnet and / or an electromagnet.

[0029] In the above scheme, lubricating grease is filled in the accommodating space 22, and the steel wire rope 1 to be lubricated is passed through the opening 21 of the housing 2 and the sealing inner hole 31 of the sealing magnetic part 3. Since ...

Embodiment 2

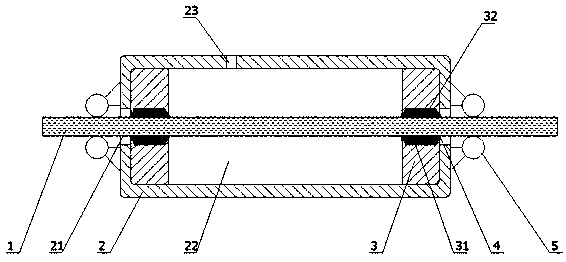

[0035] like figure 2 As shown: the difference between this embodiment and embodiment 1 is that the sealing magnetic part 3 is detachably arranged in the casing 2 . According to the diameter of the steel wire rope 1 that needs to be lubricated, the sealing magnetic parts 3 with different sizes of the sealing inner hole 31 are selected, so that the size of the sealing inner hole 31 aperture matches the diameter of the steel wire rope 1, thereby ensuring the sealing performance of the magnetic sealing device.

[0036] The casing 2 is provided with an oil filling hole 23 communicating with the accommodating space 22 . Lubricating grease can be added to the accommodating space 22 in the housing 2 through the oil filling hole 23 .

[0037] The sealing inner hole 31 of the sealing magnetic part 3 is provided with a lubricating oil placement groove. Adsorbing the magnetic grease 4 in the lubricating oil placement groove can reduce the loss of the magnetic grease 4 .

Embodiment 3

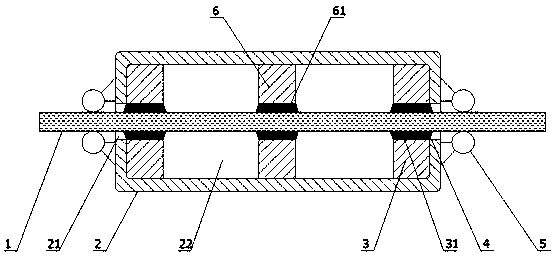

[0039] like image 3 As shown: the difference between this embodiment and embodiment 1 is that: at least one magnetic separator is arranged in the accommodating space 22, and the magnetic separator includes a separating magnetic member 6 arranged in the accommodating space 22, The separating magnetic member 6 is provided with a barrier inner hole 61 , and the barrier inner hole 61 is provided with a magnetic grease 4 .

[0040] The accommodating space 22 is divided into multiple smaller spaces by magnetic separators, ensuring the independence of each space and reducing the possibility of contamination of lubricating grease; The thickness of the grease 4 can control the amount of lubricating oil adsorbed on the steel wire rope 1, thereby gradually reducing the amount of lubricating grease absorbed on the steel wire rope 1, and preventing excessive grease from being carried out by the steel wire rope 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com