Wear-resistant multi-stage pressure reduction mechanism and application method thereof

A one-piece, inner-tube technology, applied to mechanical equipment, engine components, safety valves, etc., can solve problems such as large safety hazards, high cost, and easy wear, and achieve the effects of alleviating wear, reducing medium flow rate, and extending the operating cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0021] Aiming at the existing problems, the present invention provides an anti-wear multi-stage decompression mechanism and its application method. The anti-wear multi-stage decompression mechanism is especially suitable for use under high pressure drop and high wear conditions, and can effectively improve decompression valve working conditions, prolonging the service life of the equipment and the operating cycle of the device.

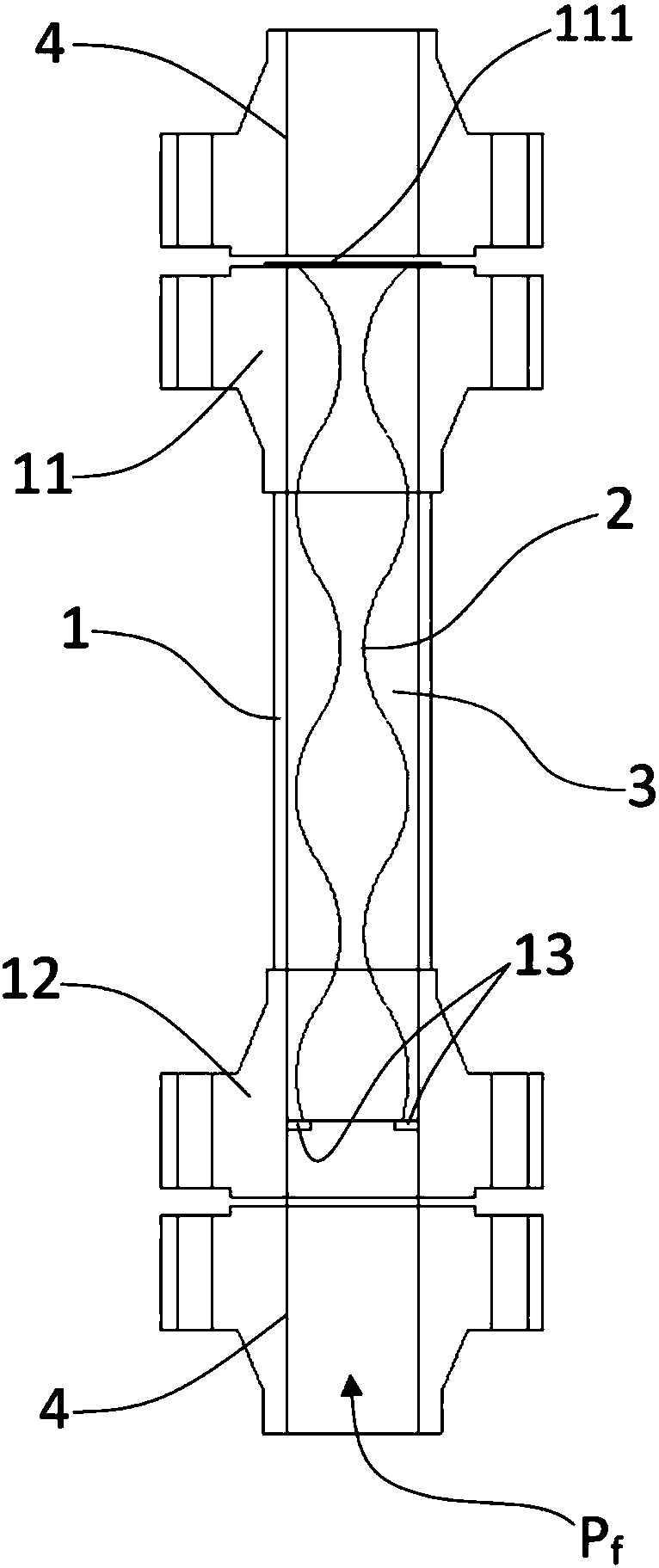

[0022] The anti-wear multi-stage pressure-reducing mechanism of this embodiment is as follows: figure 1 As shown, it includes a hollow inner cylinder 2 and an outer cylinder 1 sleeved outside the inner cylinder. There is a cavity 3 between the outer cylinder 1 and the inner cylinder 2; For the first connection part 11 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com