Guide bracket as well as guide structure of pump body of vertical type high-pressure centrifugal pump

A high-pressure centrifugal pump and guide bracket technology, which is applied to non-variable-capacity pumps, components of pumping devices for elastic fluids, pumps, etc. deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

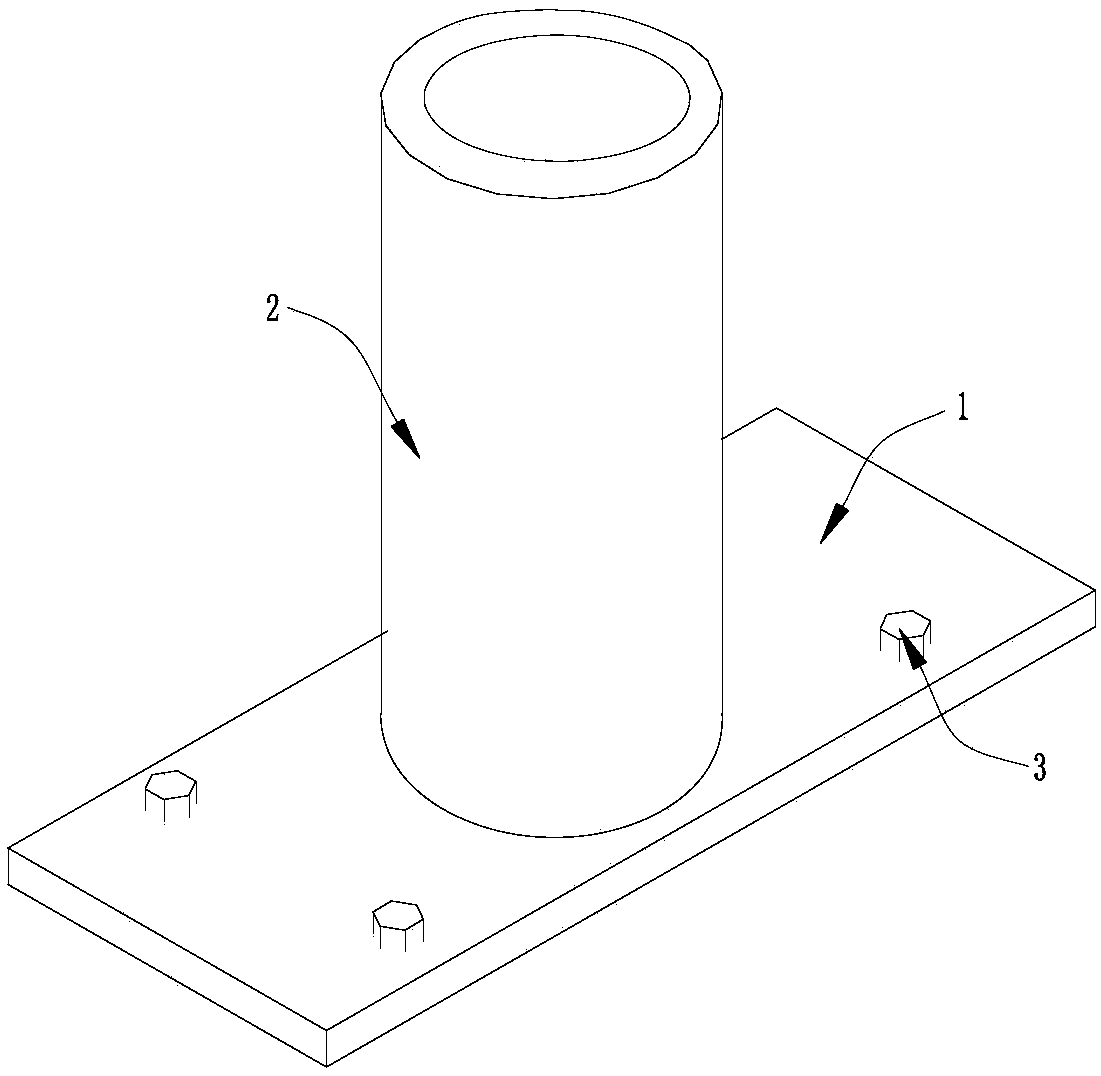

[0018] Such as figure 1 and figure 2 The shown guide bracket includes a base plate 1 and a stainless steel sleeve 2 fixed on the base plate 1 . The base plate 1 is provided with a plurality of connection holes, on which screw components 3 are mounted, and the base plate 1 is connected to the base through the screw components 3 . The screw fastening part 3 may be a bolt.

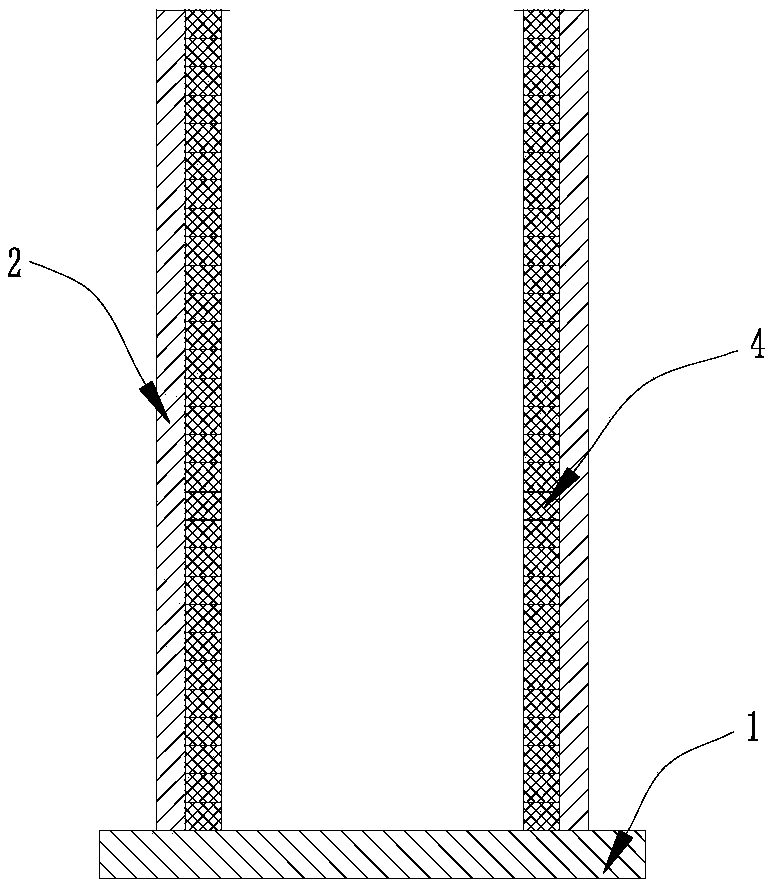

[0019] A collar 4 is arranged inside the pipe of the stainless steel sleeve 2 . The collar 4 is a polytetrafluoroethylene collar 4, the thickness of the collar 4 is 20 mm, and the outer wall surface of the collar 4 is attached to the pipe side wall of the stainless steel casing 2. This technical solution provides a guide bracket, the collar 4 of the guide bracket is a polytetrafluoroethylene collar, and the small friction coefficient between the polytetrafluoroethylene collar and the stainless steel sleeve 2 can effectively reduce the friction between the guide bracket and the stainless steel sleeve 2. T...

Embodiment 2

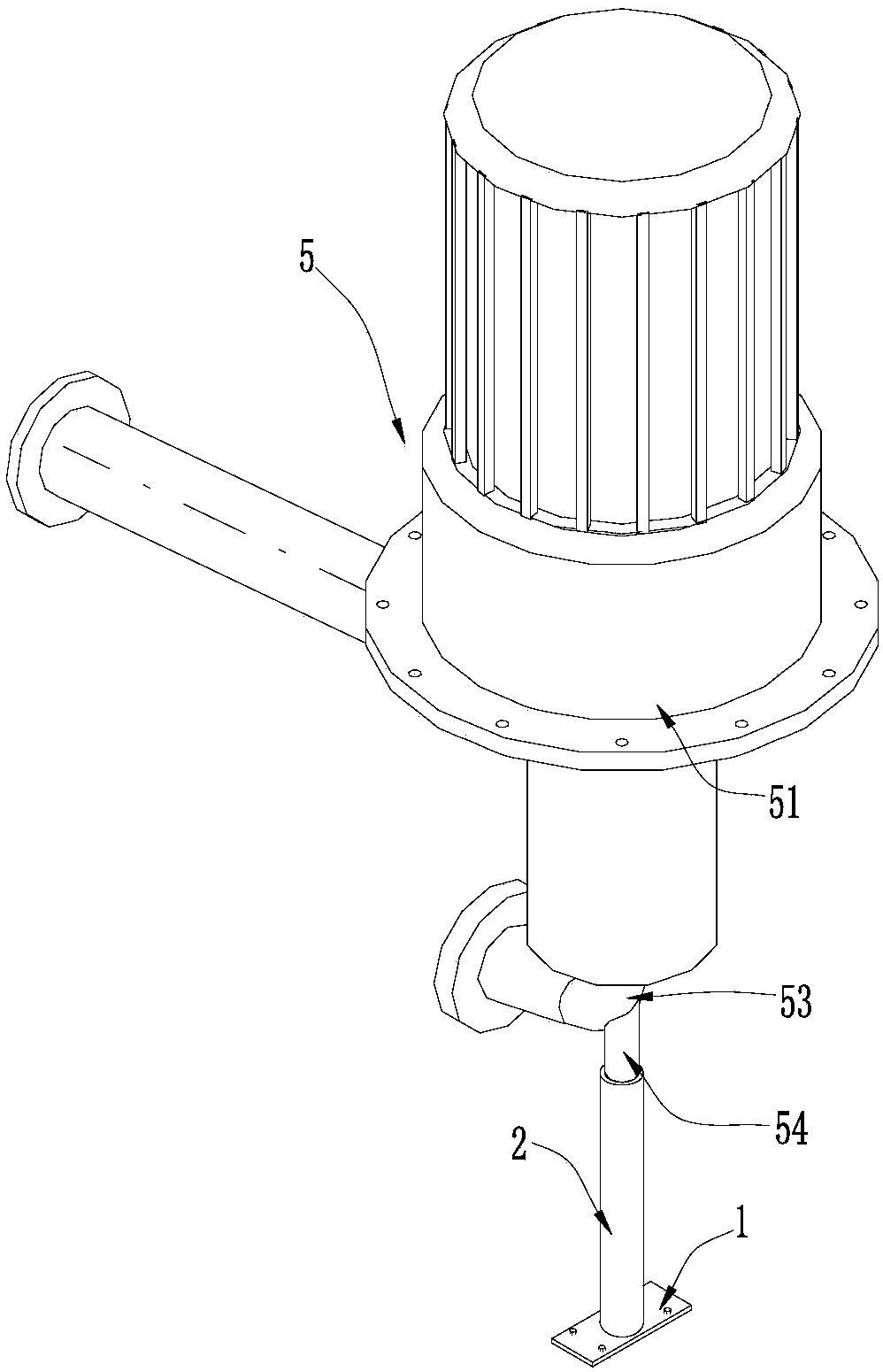

[0021] Such as image 3 and Figure 4 The guide structure of a pump body of a vertical high-pressure centrifugal pump shown includes a vertical high-pressure centrifugal pump 5 . The vertical high-pressure centrifugal pump 5 includes a casing 51 and a pump body disposed inside the casing 51 . The outlet pipe 53 of the pump body is a bent pipe, and the corner end of the bent pipe is an arc surface, and a branch pipe 54 is vertically connected to the lower end of the arc surface.

[0022] The branch pipe is supported by a guide bracket, and the guide bracket includes a base plate 1 and a stainless steel sleeve 2 fixed on the base plate 1 . The base plate 1 is provided with a plurality of connection holes, on which screw components 3 are mounted, and the base plate 1 is connected to the base through the screw components 3 . A collar 4 is arranged inside the pipe of the stainless steel sleeve 2 . The collar 4 is a polytetrafluoroethylene collar 4, the thickness of the collar 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com