Vacuum insulated panel jacketed-type refrigeration storage and construction method thereof

A technology of vacuum insulation panels and panel jackets, applied in coolers, refrigeration plants, cold storage rooms, etc., can solve the problems of low cost and low efficiency of cold air natural circulation, achieve high refrigeration efficiency, fast and efficient construction process, reduce load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

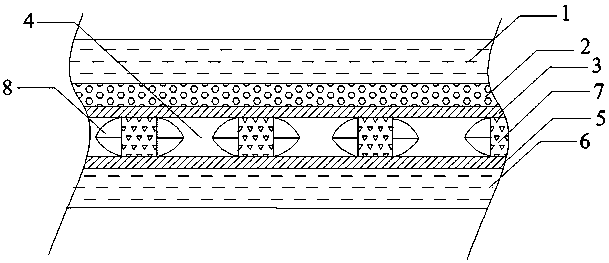

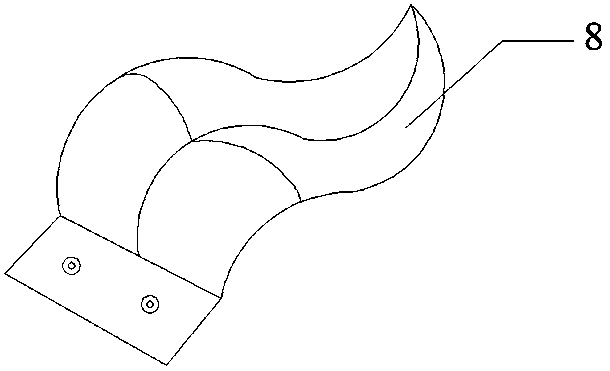

[0032] The utility model relates to a vacuum insulation board jacketed cold storage, which is a full-jacketed cold storage, that is, jackets are provided on six sides. Including the cold storage body, evaporating unit, condensing unit, and controller, the section of the cold storage body from outside to inside is the outer wall 1, the thermal insulation and gas barrier layer 2, the outer wall jacket wall 3, the wall jacket 4, and the inner wall jacket wall 5 and inner wall 6, the thermal insulation and gas barrier layer is a vacuum insulation board, a support member 7 is arranged between the jacket wall of the outer wall and the jacket wall of the inner wall, and the jacket of the wall is the jacket wall of the outer wall 1. The space formed by the jacket wall of the inner wall and the supporting part, the air guide part 8 is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com