Hammering pile sinking and synchronous pile tip and side grouting structure and process in pile tip of pile shoe-provided pipe pile

A grouting and pile end technology, which is used in foundation structure engineering, sheet pile walls, buildings, etc., to reduce side friction resistance, control construction noise, and improve the bearing capacity of single piles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further elaborated and illustrated below in conjunction with the accompanying drawings and specific embodiments. The technical features of the various implementations in the present invention can be combined accordingly on the premise that there is no conflict with each other.

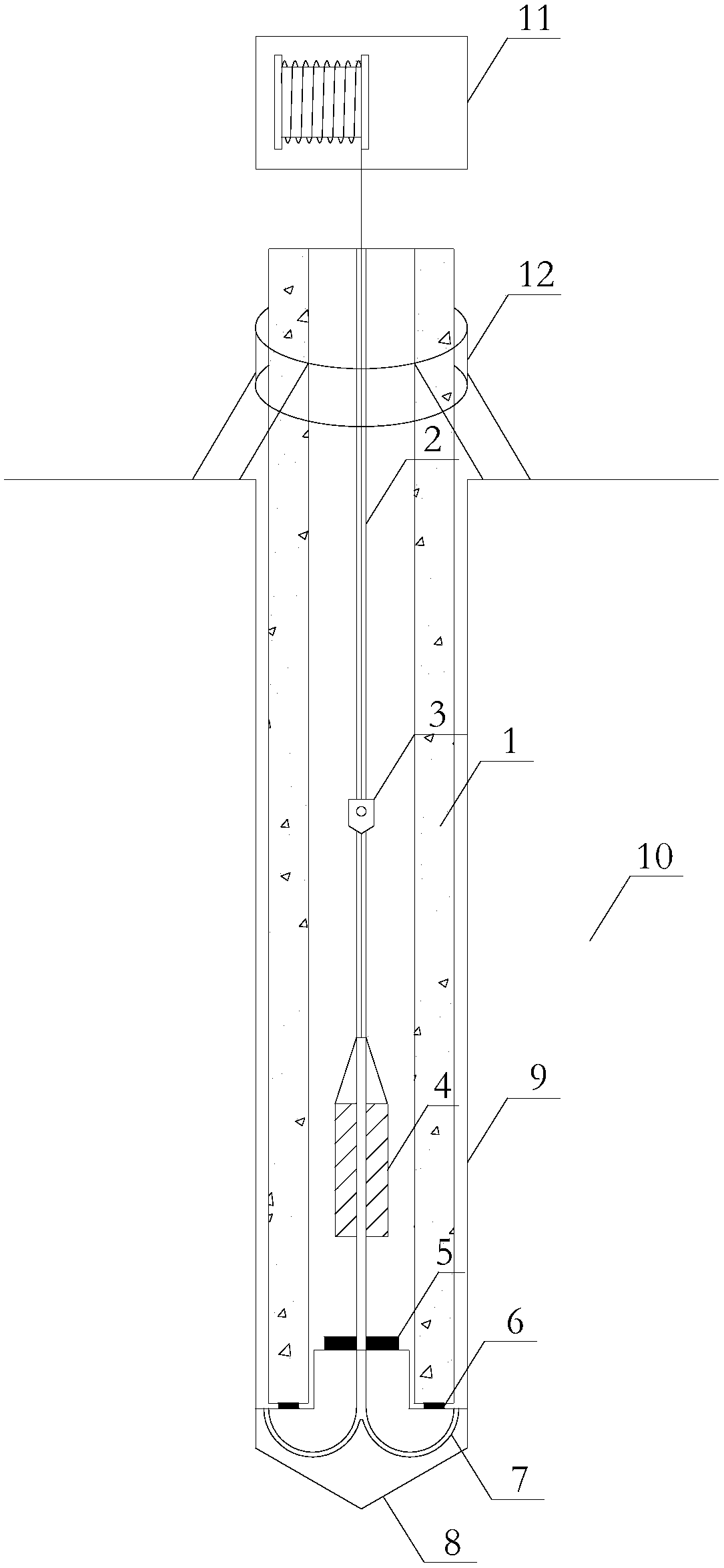

[0034] Such as figure 1 As shown in the figure, it is a schematic diagram of the internal hammering pile sinking and synchronous end measurement grouting structure of a pipe pile with a spud shoe in this embodiment. The structure includes three parts: the prestressed pipe pile 1, the enlarged pile shoe at the pile end and the power system of hammering the pile in the pipe. The enlarged spud can at the pile end includes an enlarged spud can 8, a spud can connector 6 and a pre-embedded grouting pipe 7. In-pipe hammering pile sinking power system is used to generate the power inside the prestressed pipe pile 1 to promote the sinking of the pile body. Pile frame 12. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com