High-toughness anti-cracking cement concrete and preparation method thereof

A cement concrete and anti-cracking technology, which is applied in the field of building materials, can solve the problems of concrete durability decline, concrete cracking, and low tensile strength, and achieve the effects of increasing strength, improving toughness, and improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

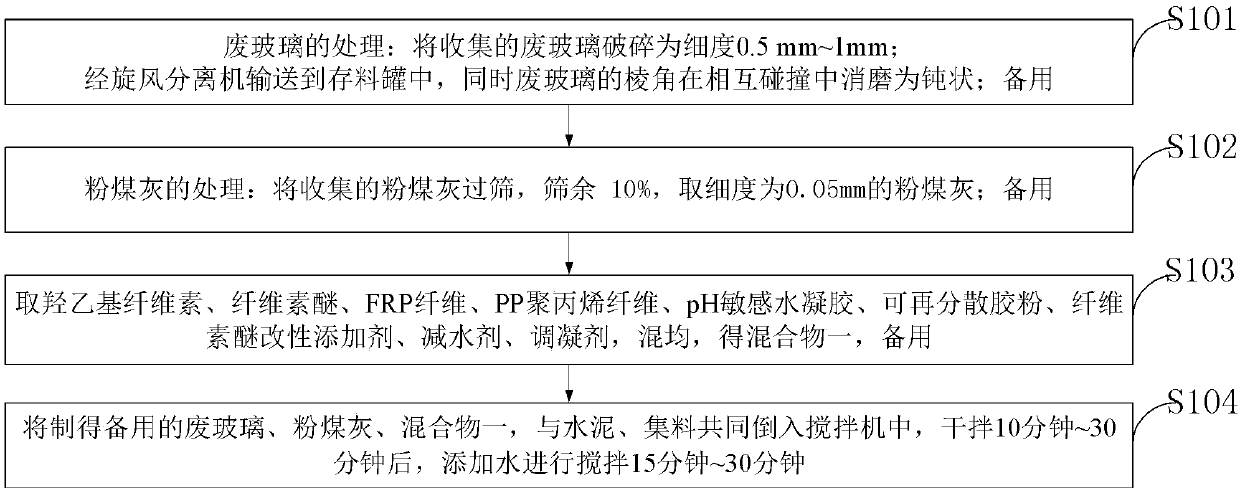

Method used

Image

Examples

Embodiment 1

[0051] The high-toughness and anti-cracking cement concrete provided by the embodiment of the present invention has the mass ratio of raw materials as 3% of hydroxyethyl cellulose, 0.2% of cellulose ether, 4% of FRP fiber, 3% of PP polypropylene fiber, and 0.2% of pH-sensitive hydrogel ~0.8%, cement 20%, aggregate 45%, redispersible rubber powder 1%~2%, cellulose ether modified additive 0.5%~1%, water reducer 1%, coagulation regulator 0.1%, waste Glass 5% and fly ash 10%. Strength can reach Cc80.

Embodiment 2

[0053] The high-toughness anti-cracking cement concrete provided by the embodiments of the present invention has the mass ratio of raw materials as 8% of hydroxyethyl cellulose, 0.8% of cellulose ether, 4%-6% of FRP fiber, 3%-5% of PP polypropylene fiber, pH Sensitive hydrogel 0.8%, cement 25%, aggregate 55%, redispersible rubber powder 1%~2%, cellulose ether modified additive 0.5%~1%, water reducing agent 1%~2%, adjusting 0.1% to 0.2% coagulant, 5% to 10% waste glass and 115% fly ash. Strength can reach Cc85.

Embodiment 3

[0055] The high-toughness and anti-cracking cement concrete provided by the embodiments of the present invention has the mass ratio of raw materials as 5% of hydroxyethyl cellulose, 0.5% of cellulose ether, 5% of FRP fiber, 3% to 5% of PP polypropylene fiber, and pH-sensitive hydraulic coagulation Glue 0.2%~0.8%, cement 22%, aggregate 50%, redispersible rubber powder 1%~2%, cellulose ether modified additive 0.5%~1%, water reducing agent 1%~2%, adjusting 0.1% to 0.2% coagulant, 5% to 10% waste glass and 12% fly ash. Strength can reach Cc82.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com