Novel automatic spraying robot for ship

An automatic spraying and robot technology, applied in the direction of soldering iron, welding position, tin feeding device, etc., can solve the problems of inability to ensure the alignment of weldments, mutual disconnection of tin spots and solder joints, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

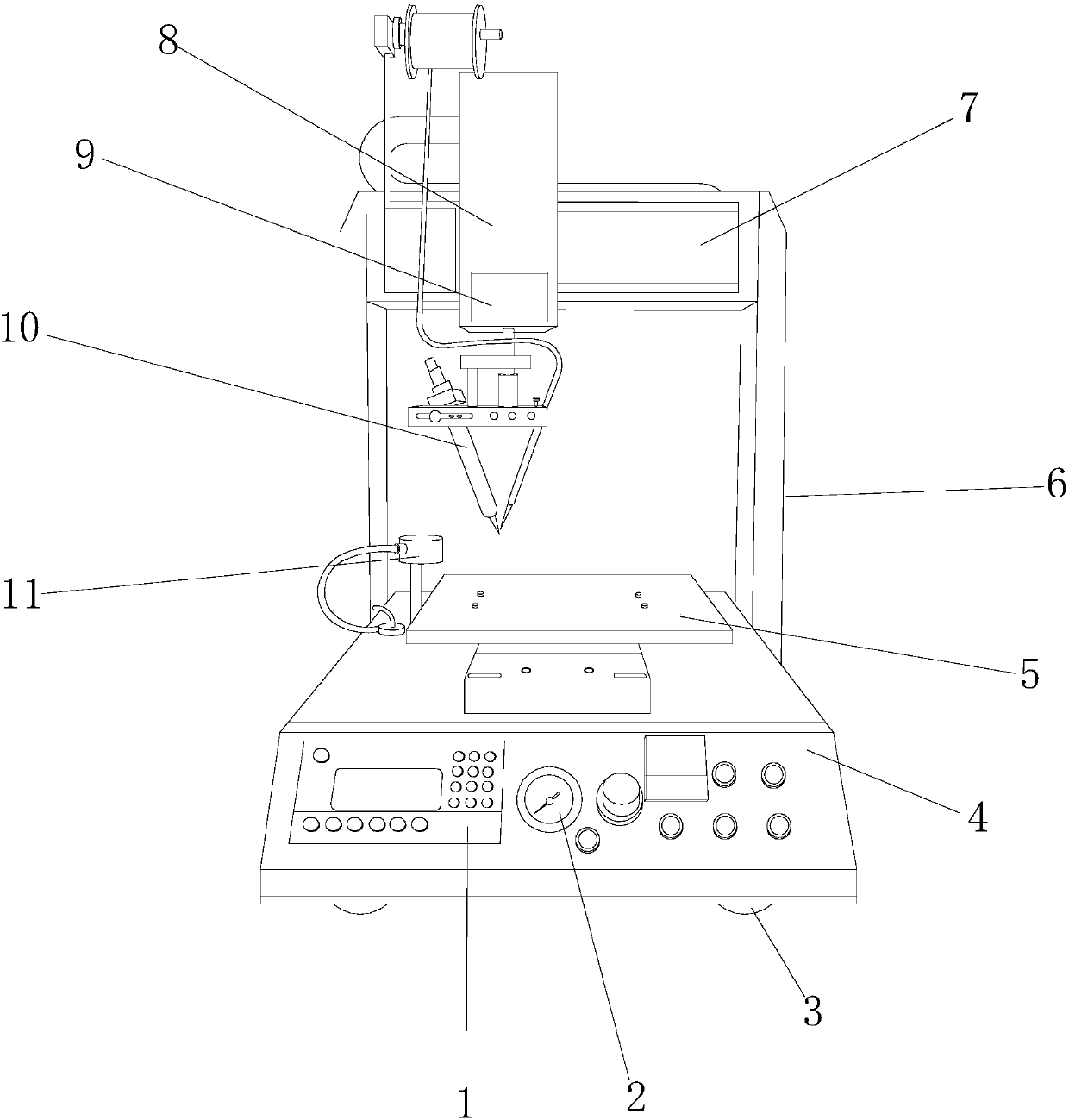

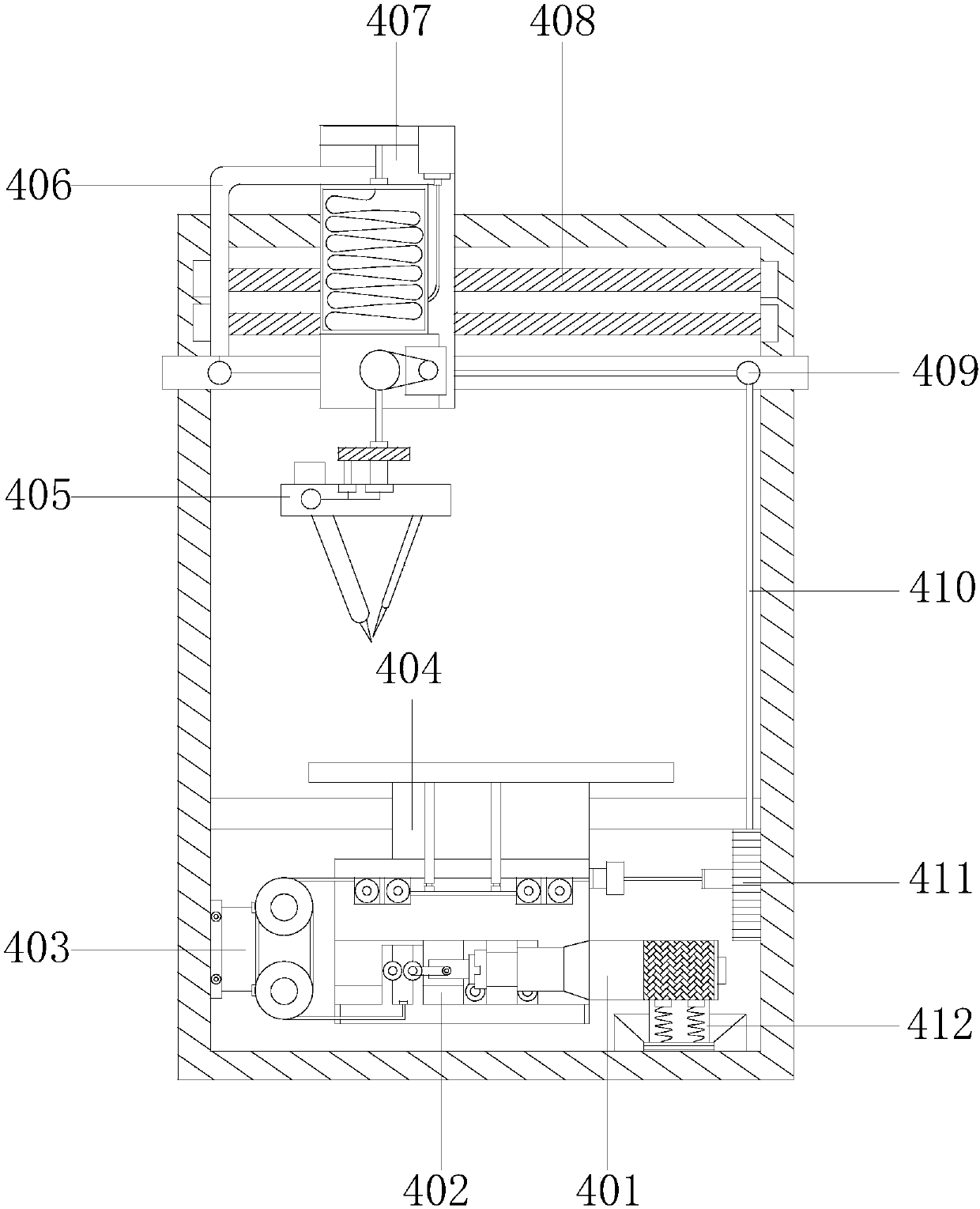

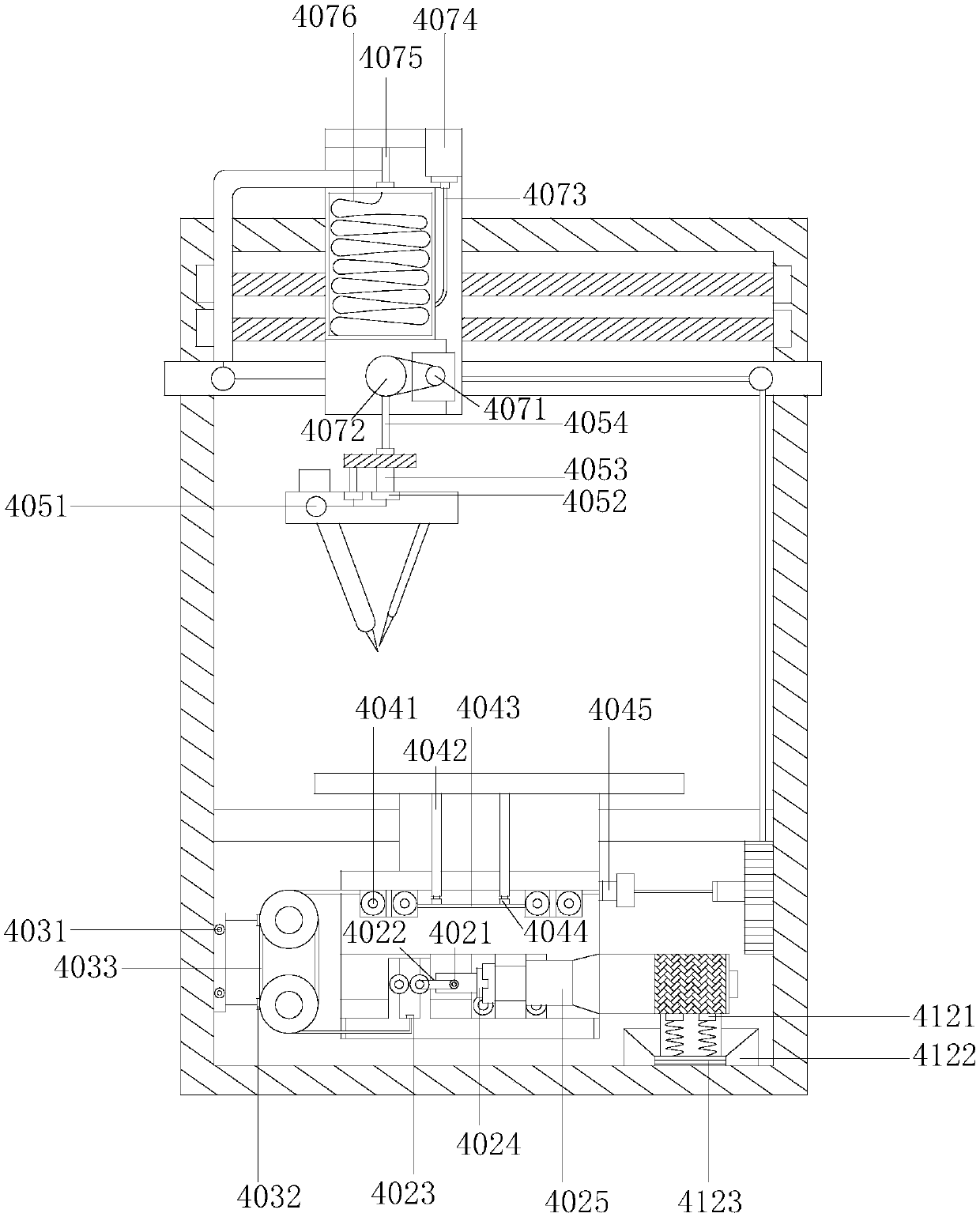

[0015] see Figure 1-Figure 4, the present invention provides a new type of marine automatic spraying robot technical solution: its structure includes: system operation panel 1, pressure gauge 2, foot 3, machine base 4, workbench 5, column 6, beam 7, tin feeding mechanism 8, Model mark 9, electric soldering iron 10, tin blowing mechanism 11, the system operation panel 1 has a rectangular cross-section and is horizontally attached to the front end of the machine base 4 and is mechanically connected, and the pressure gauge 2 is horizontally fixed on the right end of the system operation panel 1 And adopt electric connection with machine base 4, described base 3 is provided with four altogether and is vertically fixed on the lower end of worktable 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com