Communication machine room with electrostatic dust removing function

A communication room, electrostatic dust removal technology, applied in the field of computer rooms, can solve the problems of not being able to effectively filter dust, unsatisfactory dust removal effect, damage to health, etc., to achieve the effect of extending the air filtration path, better dust removal effect, safe and practical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

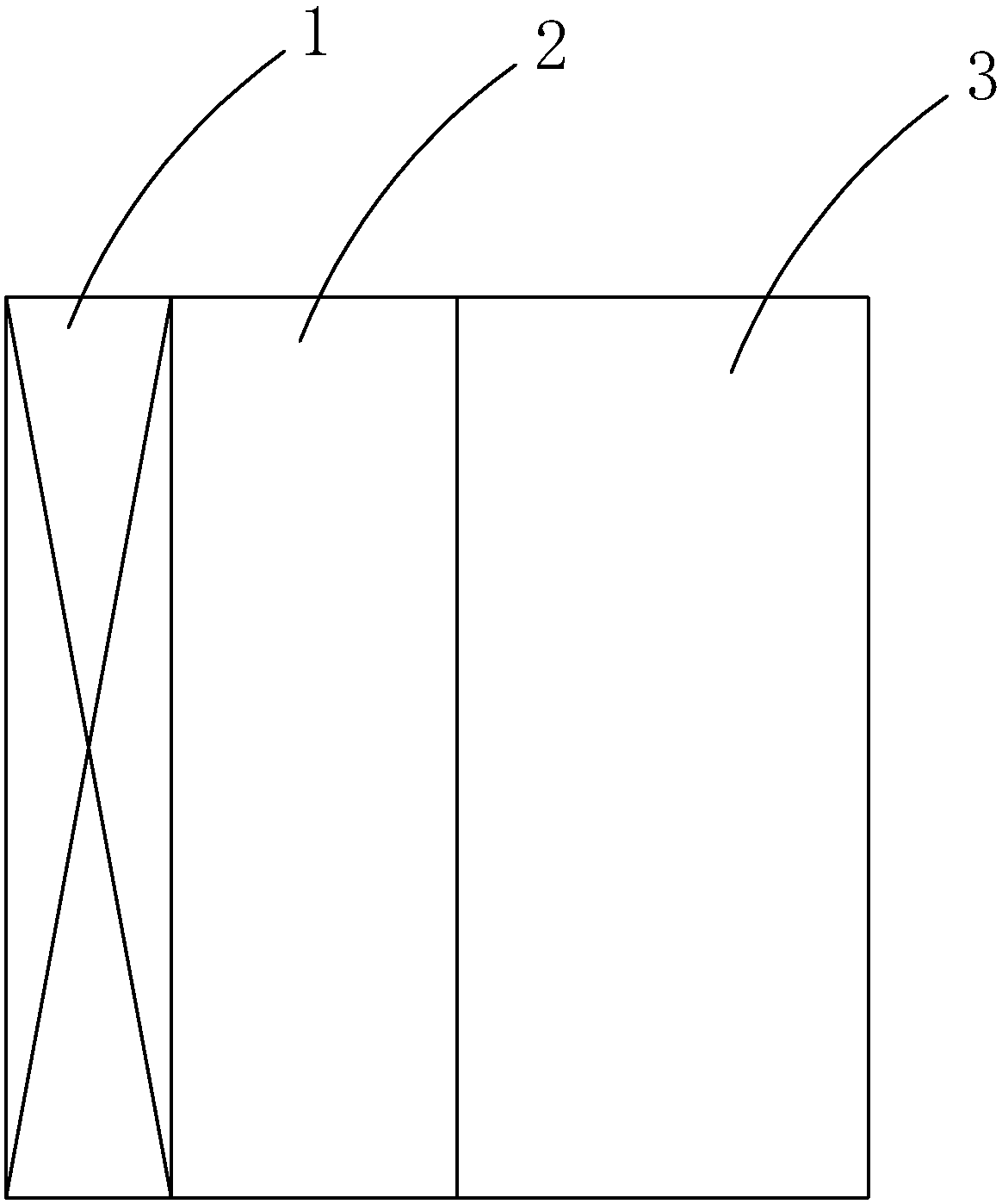

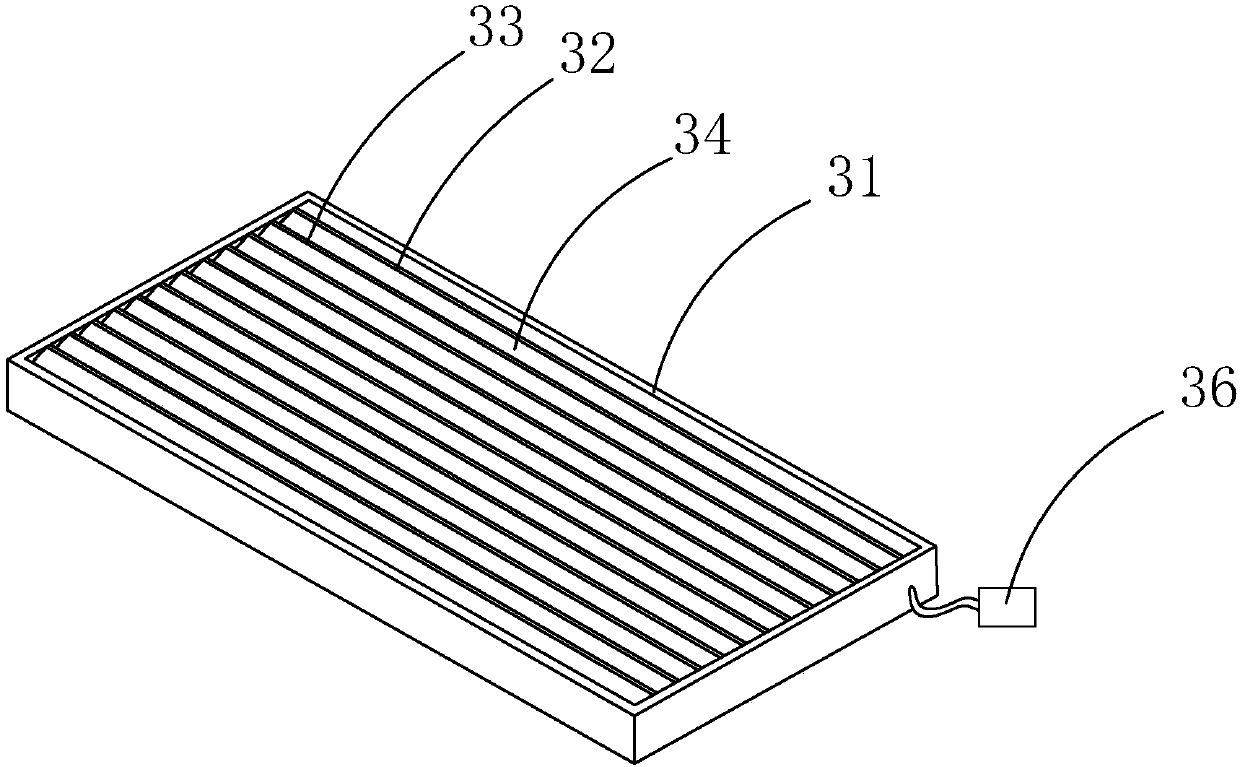

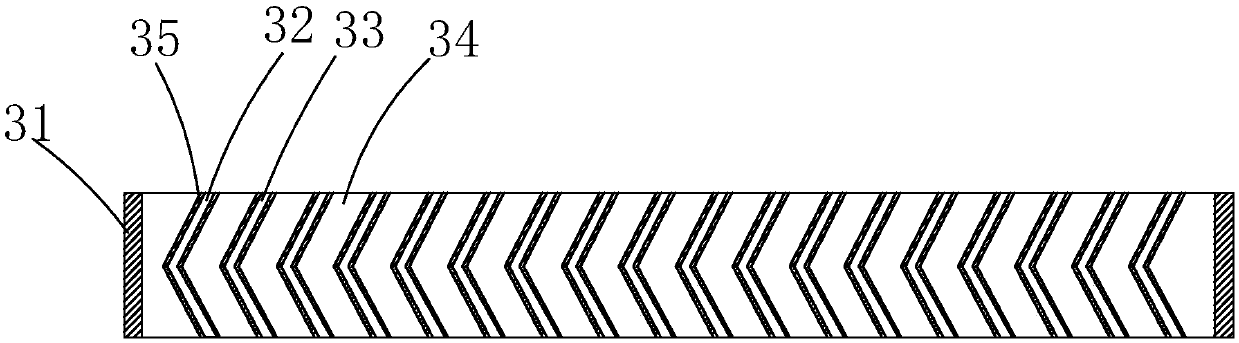

[0018] refer to figure 1 and 2 , a communication machine room with electrostatic dust removal of the present invention comprises a room body, a dust removal device is provided on the air vent of the room body, and the dust removal device includes a housing, an air inlet and an air outlet arranged on the housing, and is composed of From the air inlet to the air outlet, an exhaust fan 1, a polarizer 2 and an electrostatic adsorber 3 are arranged in sequence, wherein the air inlet of the exhaust fan 1 is provided with a dust cover, through which the sucked air can be filtered. To filter out larger dust particles, the polarizer 2 includes a negative high-voltage particle generator, a charged ground plate, and a charged electrode plate. The charged electrode plate is provided with a plurality of through holes for air to pass through, and a plurality of through holes for the passage The charged electrode corresponding to the hole, using the principle of tip discharge, the tip of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com