Feeding device for automobile perfume core processing

A technology of feeding device and pressurizing device, which is applied in transportation and packaging, mixed material pretreatment, mixer and other directions, can solve problems such as inconvenience in use, and achieve the effect of reducing impurities, improving feeding efficiency and good fixing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

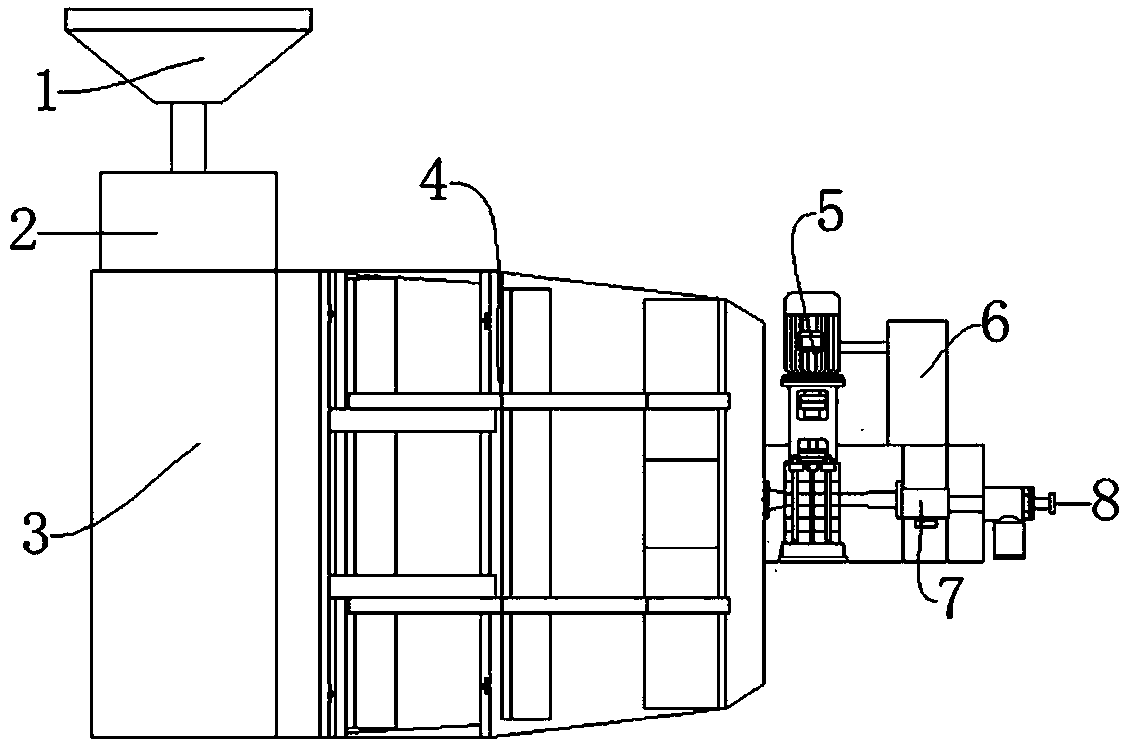

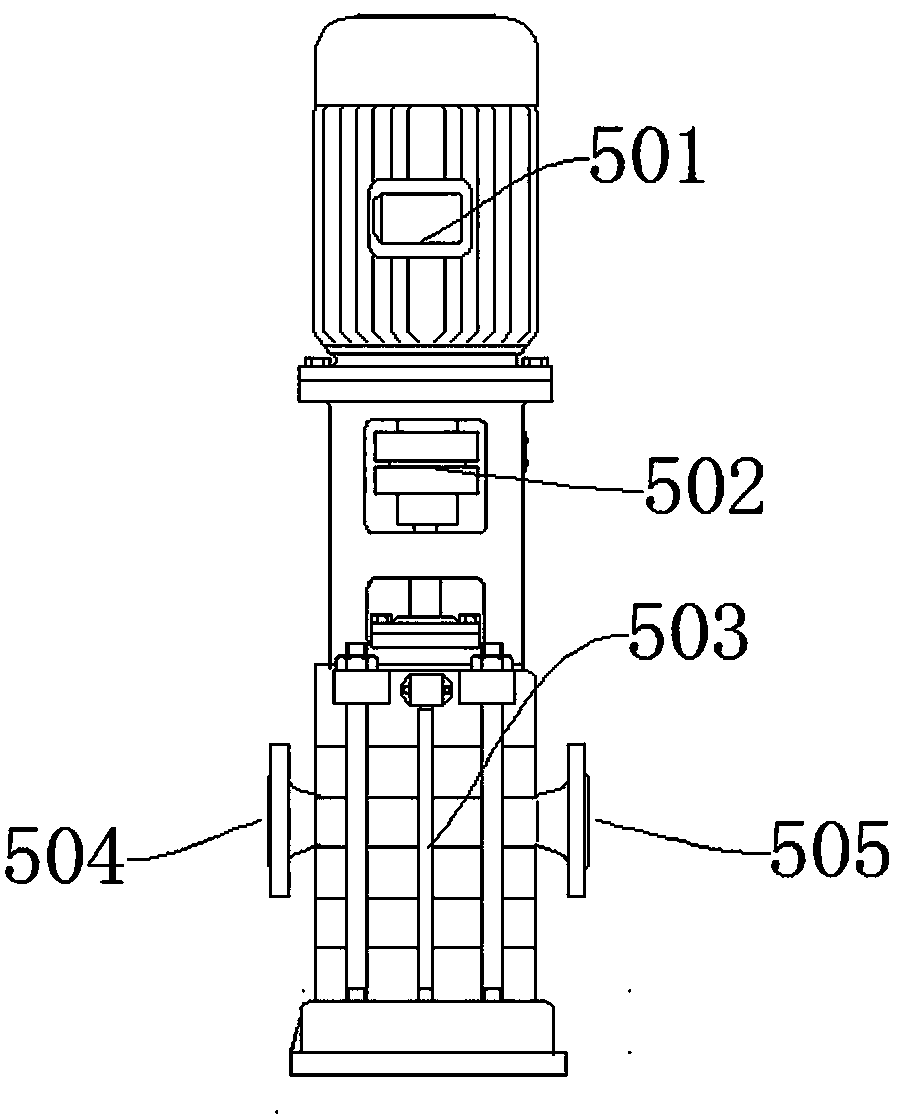

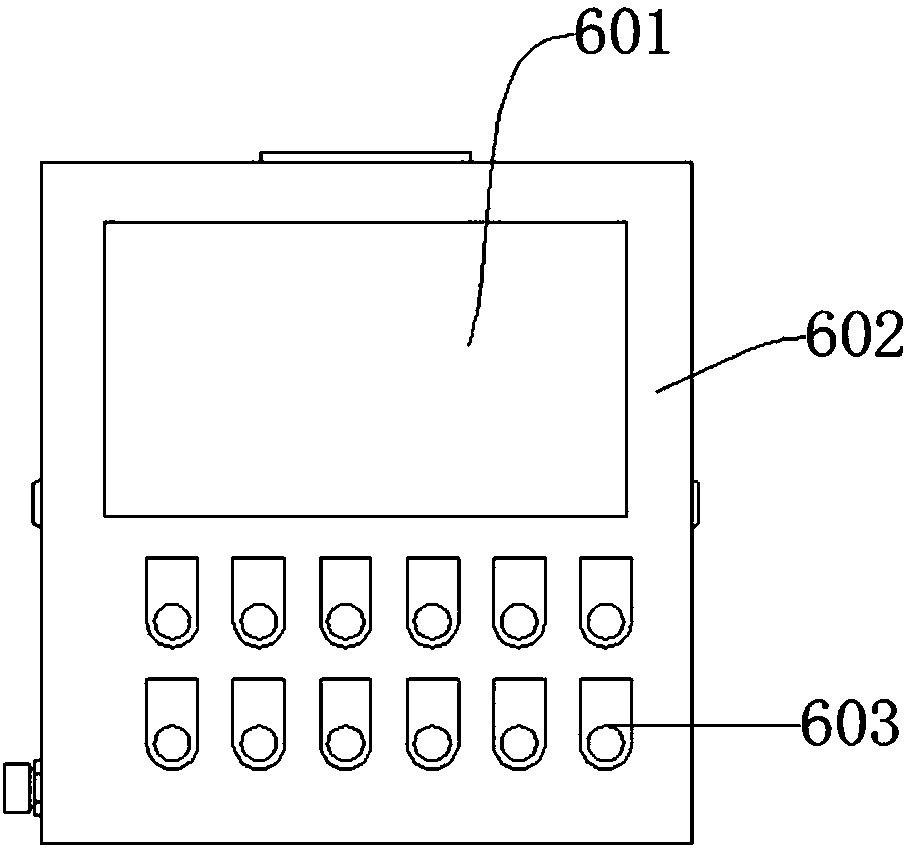

[0021] Such as Figure 1-Figure 3 As shown, a feeding device for automobile perfume core processing includes a storage bin 4 and a pressurizing device 5, a slow flow chamber 3 is arranged on the side of the storage bin 4, a filter 2 is arranged above the slow flow chamber 3, and a filter 2 is arranged above the filter 2 A feeding funnel 1 is provided, and a pressurizing device 5 is provided on the other side of the storage bin 4. The pressurizing device 5 is composed of a motor 501, a coupling 502, a pressurizing pump 503, a feeding pipe 504 and a discharge pipe 505. The motor 501 is connected with booster pump 503 through coupling 502, and both sides of booster pump 503 are provided with feed pipe 504 and discharge pipe 505, and pressurization device 5 is connected with control device 6, and control device 6 is controlled by display screen 601 , PLC controller 602 and fun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com