Method for manufacturing customized orthodontic square wire

A technology of orthodontics and manufacturing methods, which is applied in the field of manufacturing custom-made orthodontic devices, can solve problems such as not being easy to bend, unable to draw teeth, etc., and achieve the effect of small tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] preferred implementation

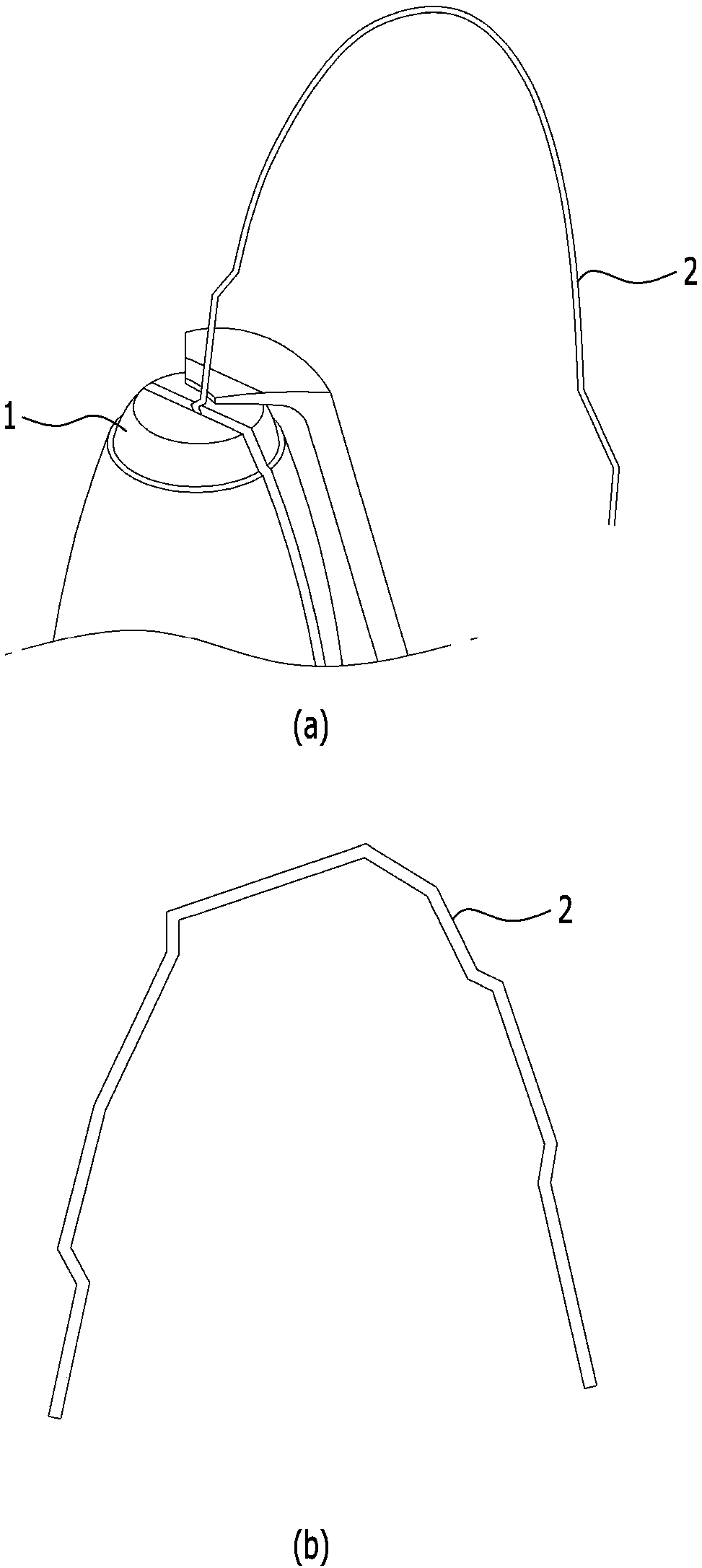

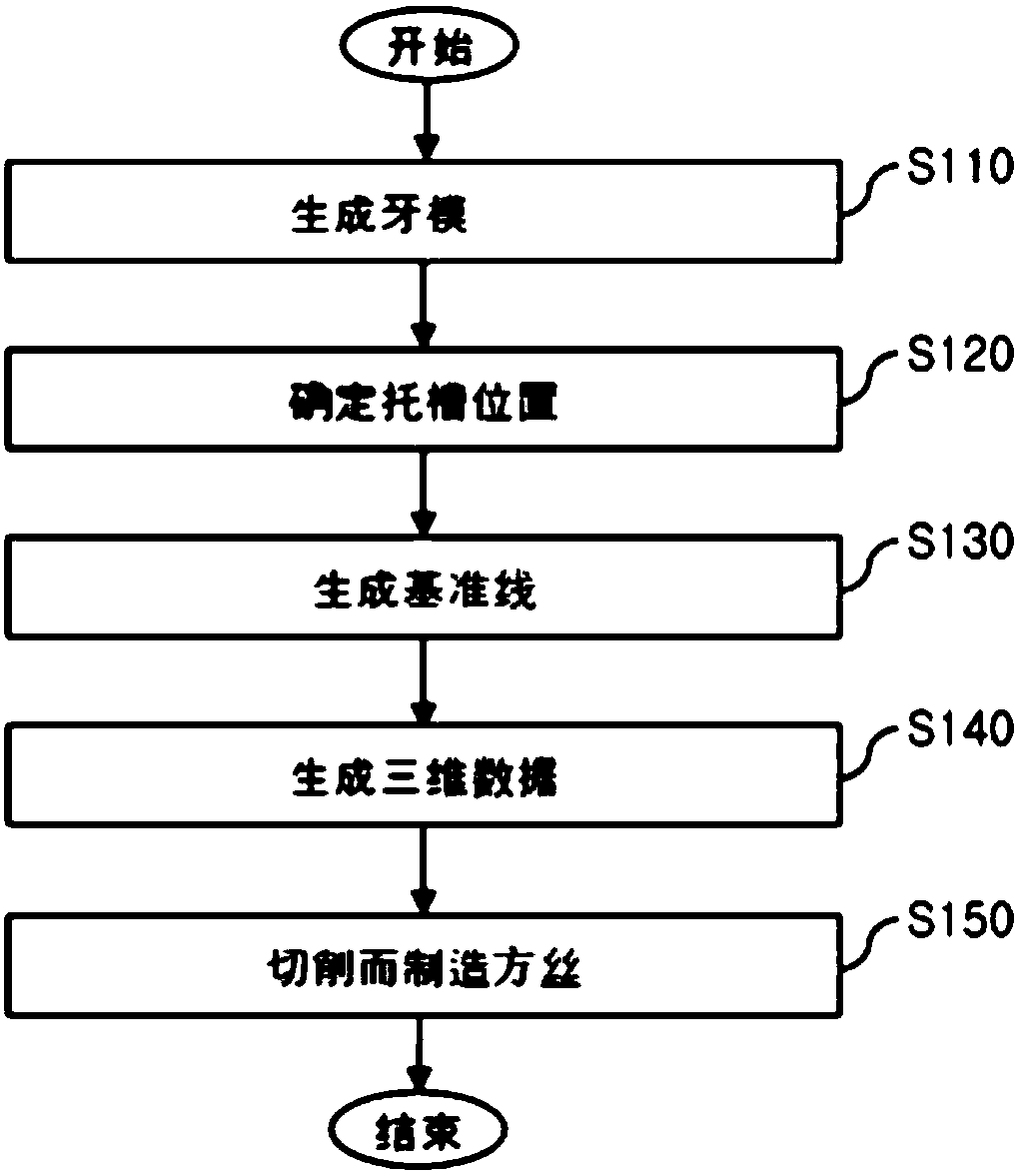

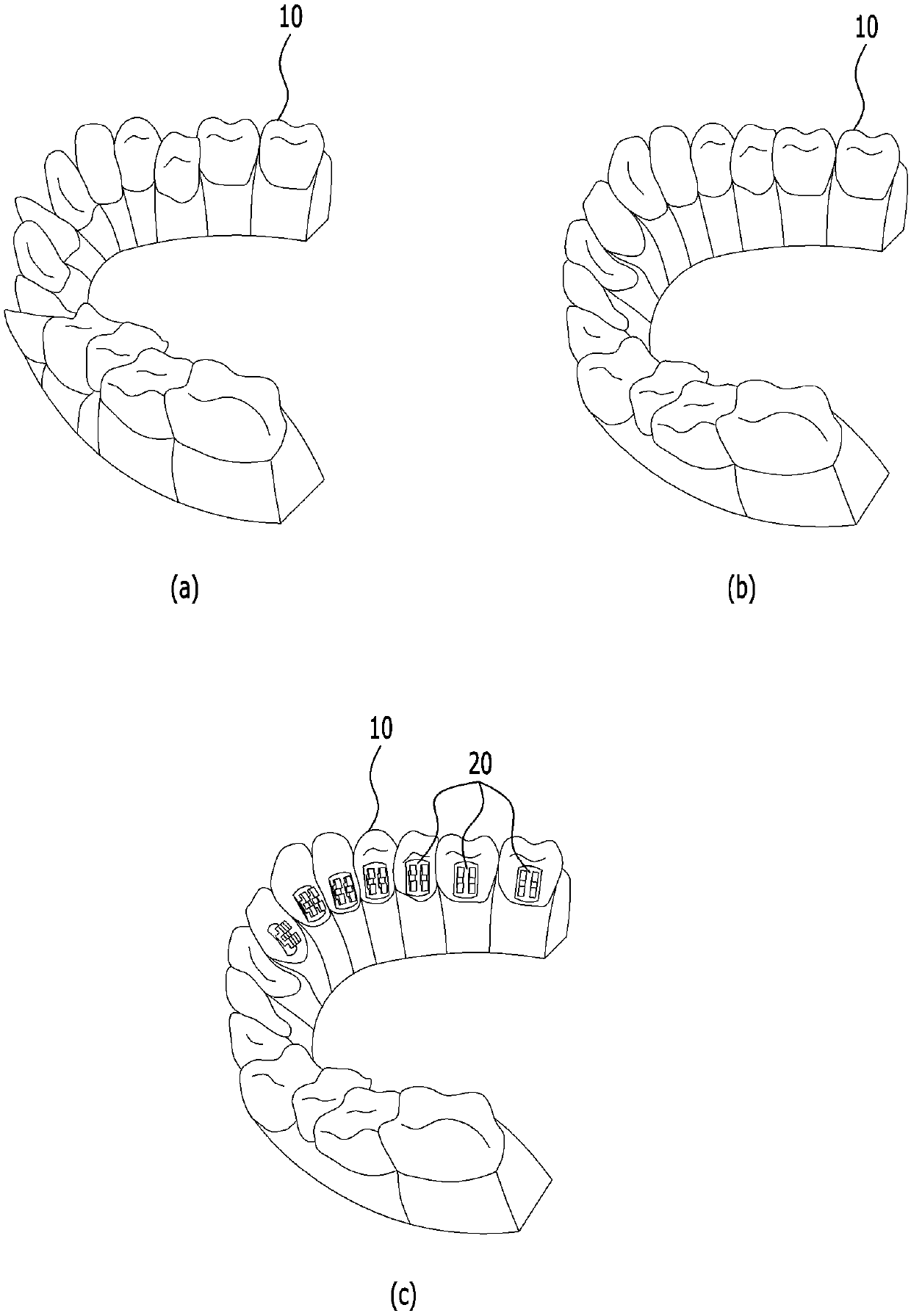

[0048] Hereinafter, the present invention will be specifically described with reference to preferred embodiments of the present invention and the accompanying drawings, and the same reference numerals in the drawings will denote the same constituent elements as a whole.

[0049] It should be understood that within the scope of the specific description or claims of the invention, when it is said that any constituent element "includes" another constituent element, in the absence of an exclusive statement, it is not limited to being composed of only the constituent element. To explain, also include other constituent elements.

[0050] Next, the manufacturing method of the custom-made square wire for orthodontics of the present invention will be specifically described with reference to the accompanying drawings.

[0051] First, the dental model 10 of the patient's teeth is manufactured (S110).

[0052] The making of the dental model 10 is genera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com