Regulation assembly for a cigarette manufacturing machine and method for regulating the transport of the cigarette filler

A control device and manufacturing machine technology, applied in the direction of manufacturing cigarettes, applications, tobacco, etc., can solve problems such as wear, inability to prevent changes, flow resistance changes, etc., and achieve the effect of simplifying expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

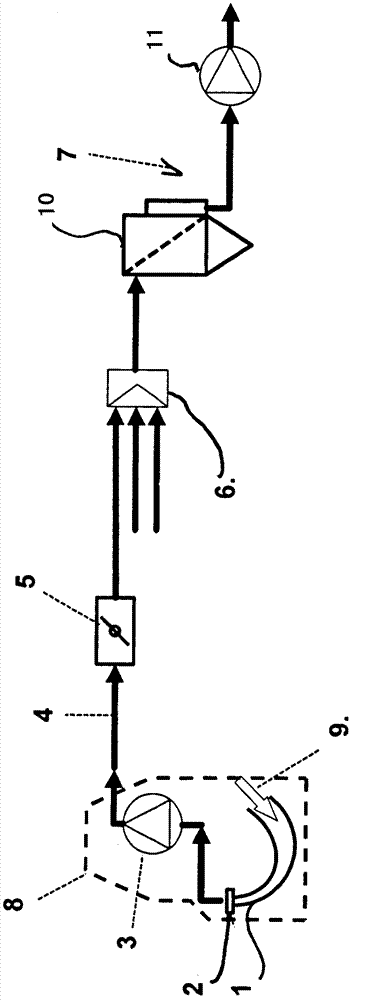

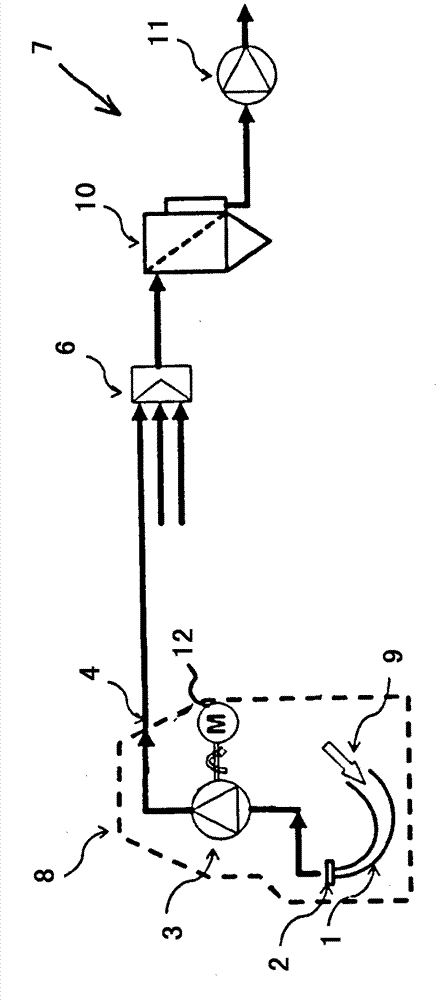

[0022] The exemplary control device according to the invention has a controlled throttling device 5 and a measuring device 4 for measuring the inlet to the exhaust device from the air delivery device 3 integrated in the cigarette making machine 8 in the example shown. 6 Delivery flow. The exhaust device 7 shown as an example here has a vacuum generating device 11 and a filter device 10 and has a plurality of inlets 6, so that several cigarette making machines 8 with the control device according to the invention can be connected to a common exhaust device 7 superior. Cigarette filling 2 is fed via feed device 1 to conveying medium 2 . In this case, specific inhalation speeds and flow conditions are set in the region of the inlet device 1 as a function of the air flow through the conveying medium 2 , which must be optimized accordingly for each cigarette filler, in particular for each tobacco type. selected so as to achieve optimum properties of the cigarette rod formed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com