Weight-loss machine

The technology of a weightless machine and a support rod, which is applied in the direction of a lifting device and the like, can solve the problems of ineffective recovery and utilization of gravitational potential energy, laborious, inconvenient force application, etc., and achieve the effects of simple structure, convenient force application, and simple and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In the weightless machine of the present invention, "weightlessness" is not the state of weightlessness in physics, but the weight is lifted with a force much smaller than the weight of the lifted object, so that it is equivalent to the weightless state of the heavy object on the surface, so it is named the weightless machine .

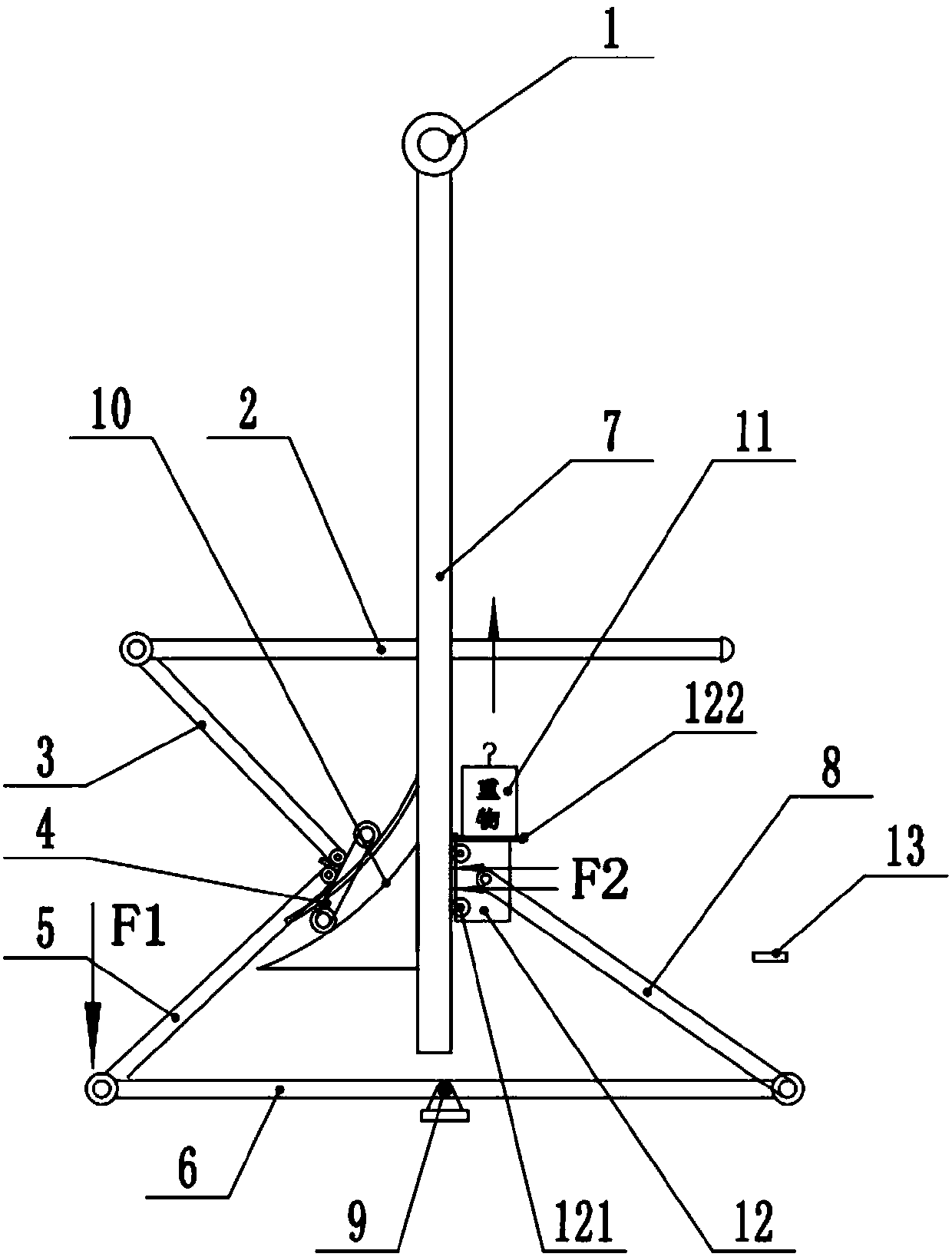

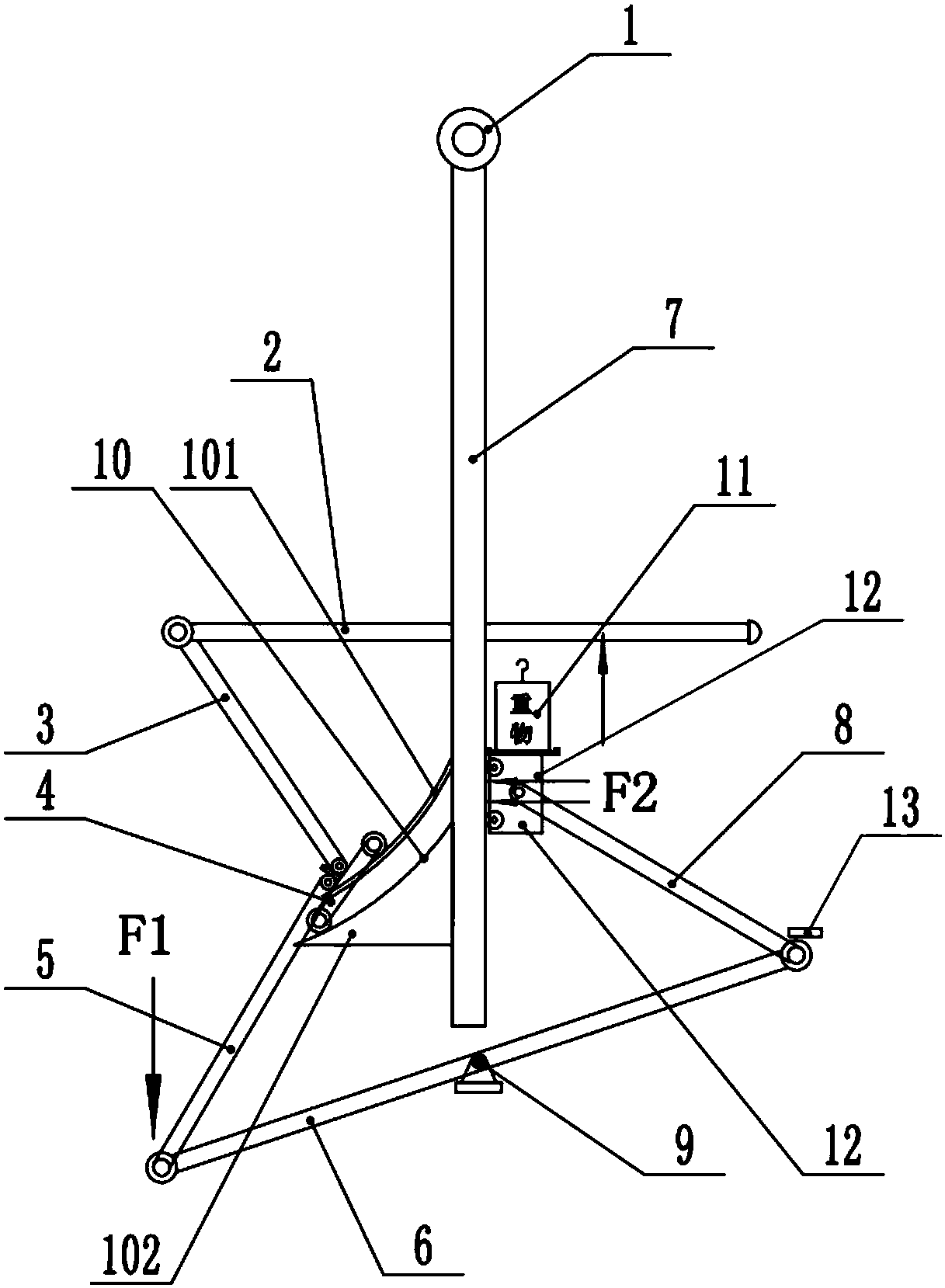

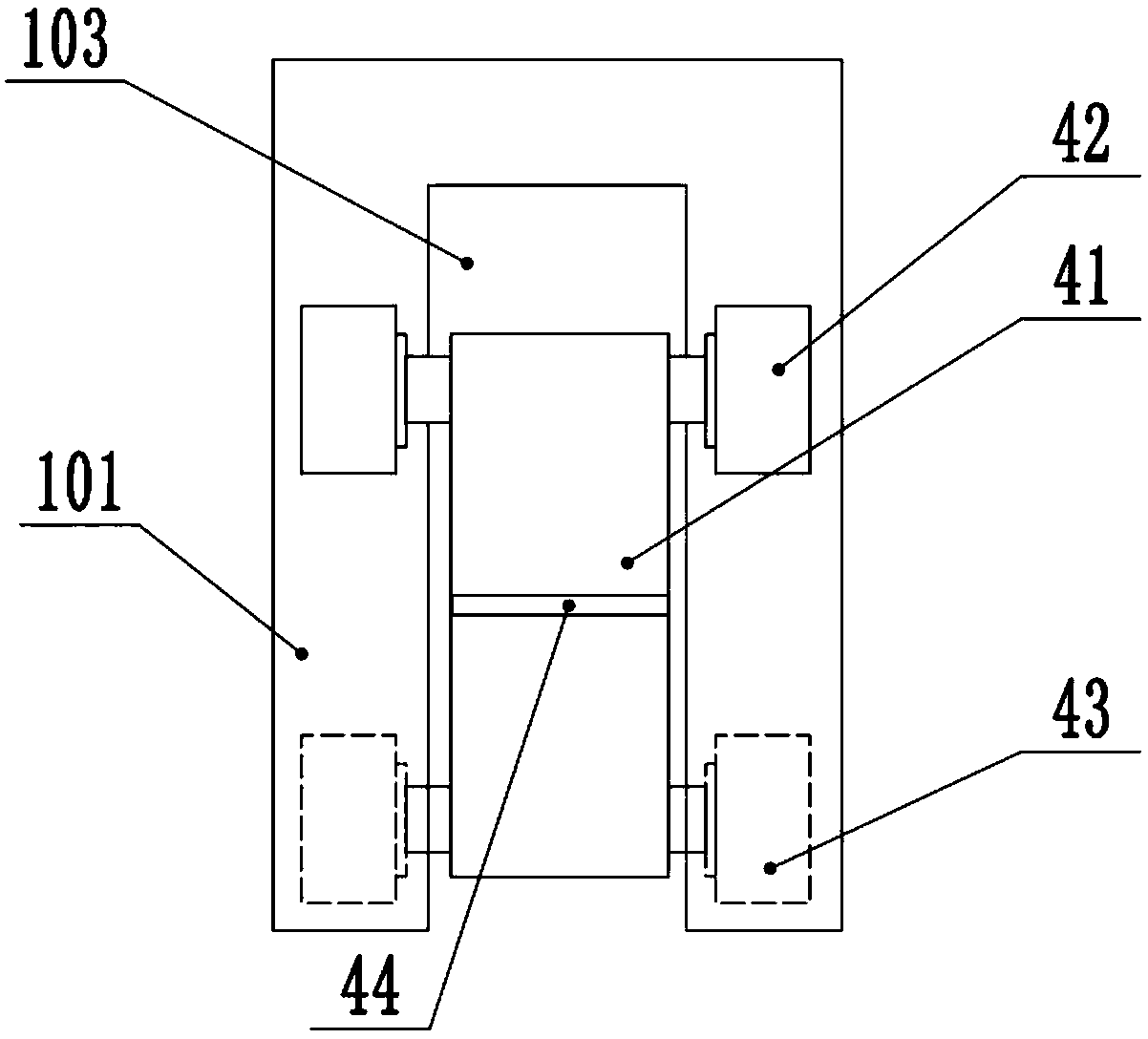

[0024] see Figure 1-3 , the present invention provides the following technical solutions:

[0025] Such as figure 1 , figure 2 As shown, the weightless machine of this embodiment includes a fixed seat 1, a tie rod 2, a first movable support rod 3, a movable assembly 4, a second movable support rod 5, a balance bar 6, a movable plate 7, and a third movable support rod 8. Support base 9, weight 11; the movable plate 7 is installed under the fixed base 1 and can swing around the fixed base 1; Movable support rod 3, one end of the first movable support rod 3 away from the tie rod 2 passes through the guide assembly 10 on the side of the movab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com