Multi-piece compression roller assembly and method for manufacturing pneumatic tire

A pressing roller assembly and technology of the assembly are applied in the tire preparation device and the preparation field thereof, which can solve the problems of low reliability of the vacuum suction cup, and achieve the effects of avoiding the head falling phenomenon, avoiding the falling and reducing the safety risk.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the following embodiments in no way limit the present invention.

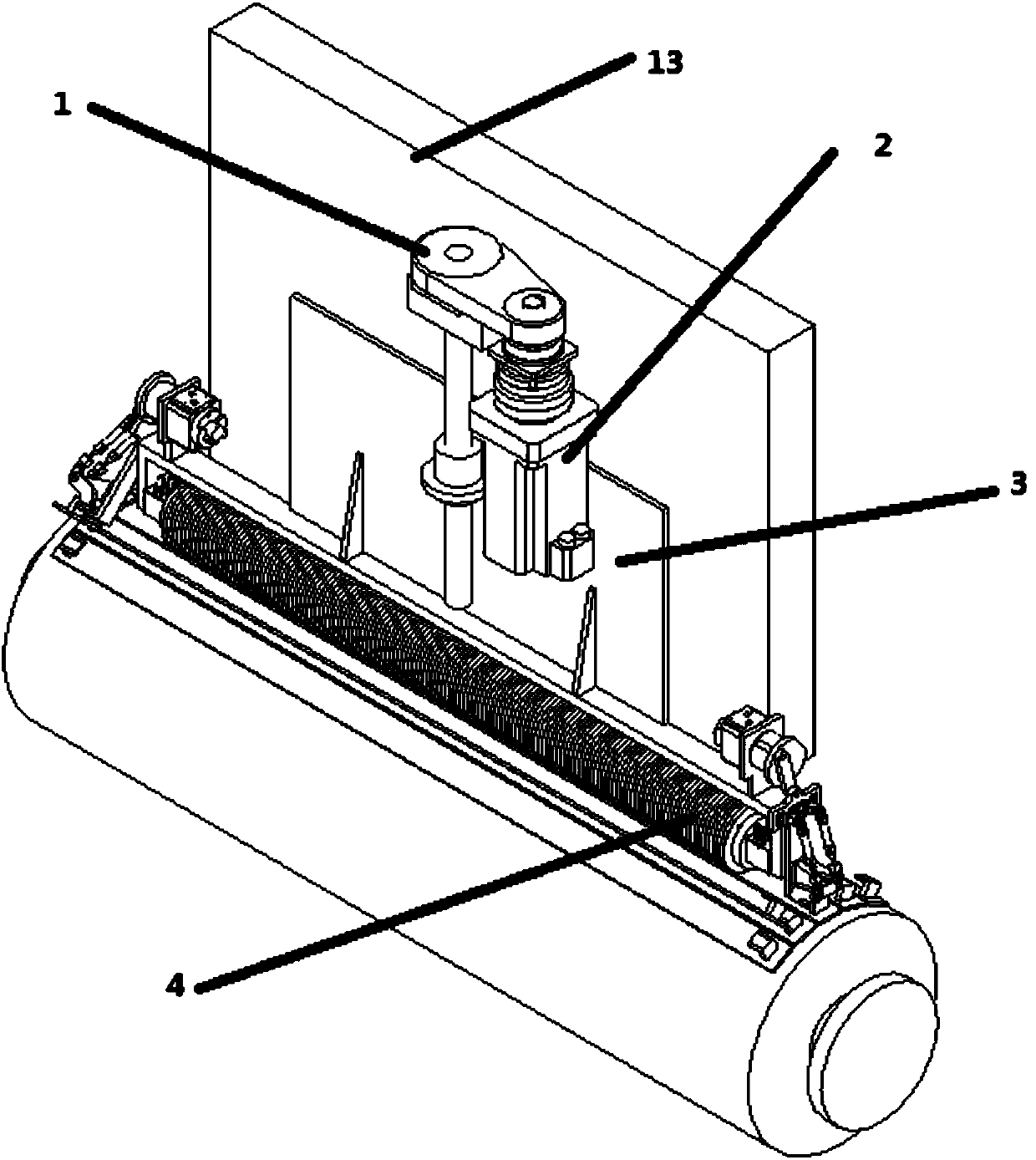

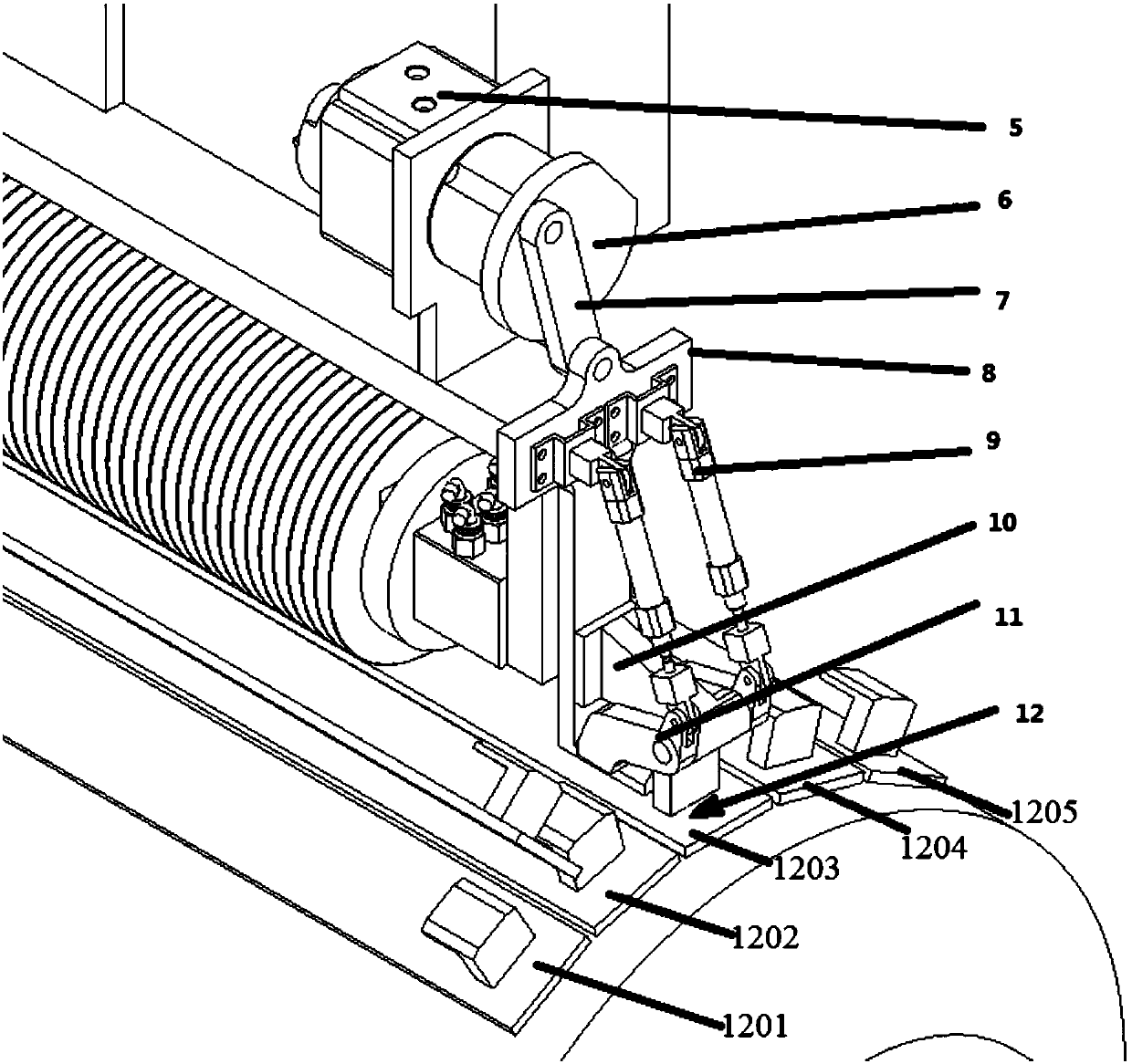

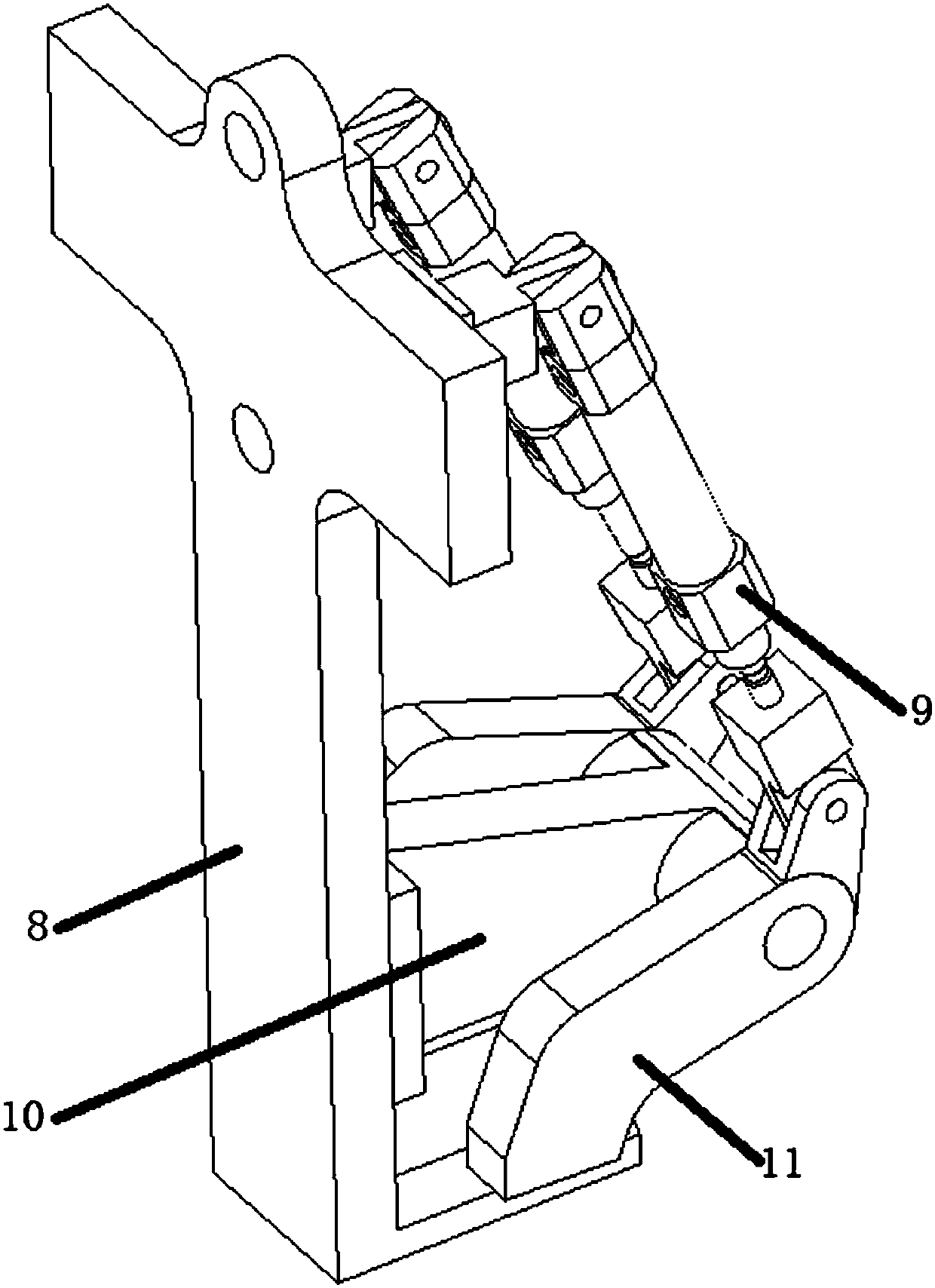

[0030] Such as Figure 1-2 As shown, the multi-piece pressing roller assembly includes: lifting screw assembly 1, power output assembly 2, lifting slide table 3, multi-piece pressing roller 4, rotating cylinder 5, rotating driver 6, swinging up and down connecting rod 7, swinging up and down Drop the base 8, the cylinder group 9, the rotating shaft bracket 10, the swing stopper 11 and the head clamping plate 12;

[0031] Wherein, the lifting slide table 3 is a vertically arranged plate structure; the power output end of the power output assembly 2 is connected with the lifting screw assembly 1, and is vertically arranged in the middle of the facade of the lifting slide table 3, and the power output assembly 2 passes through The lifting screw assembly 1 drives the lifting move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com