Traditional Chinese medicine material slicing device capable of automatically controlling slice thickness

A technology of slicing thickness and slicing device, applied in metal processing and other directions, can solve problems such as low efficiency, difficult to control precision, and inability to suppress materials, and achieve the effects of high degree of automation, convenient feeding and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

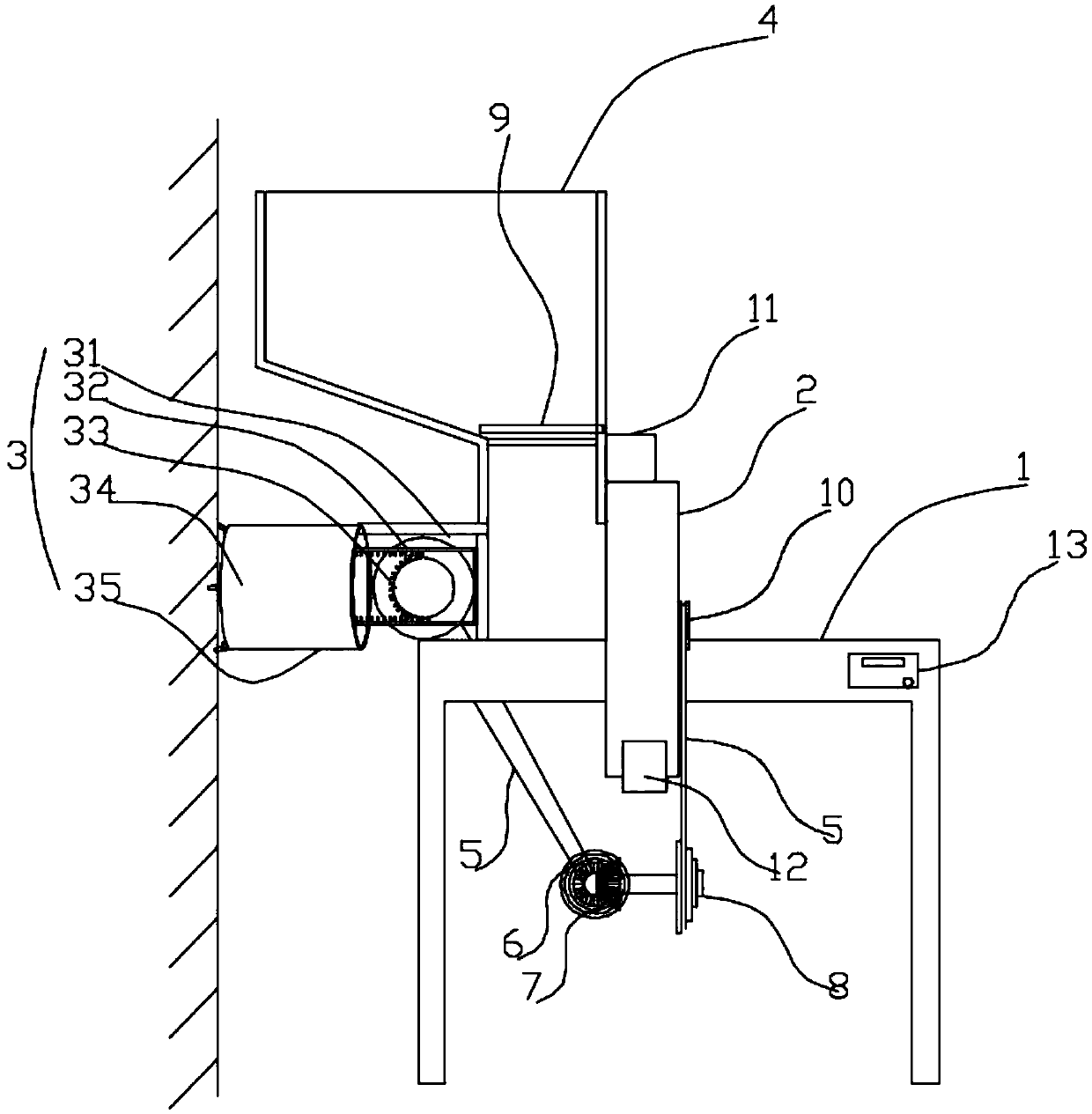

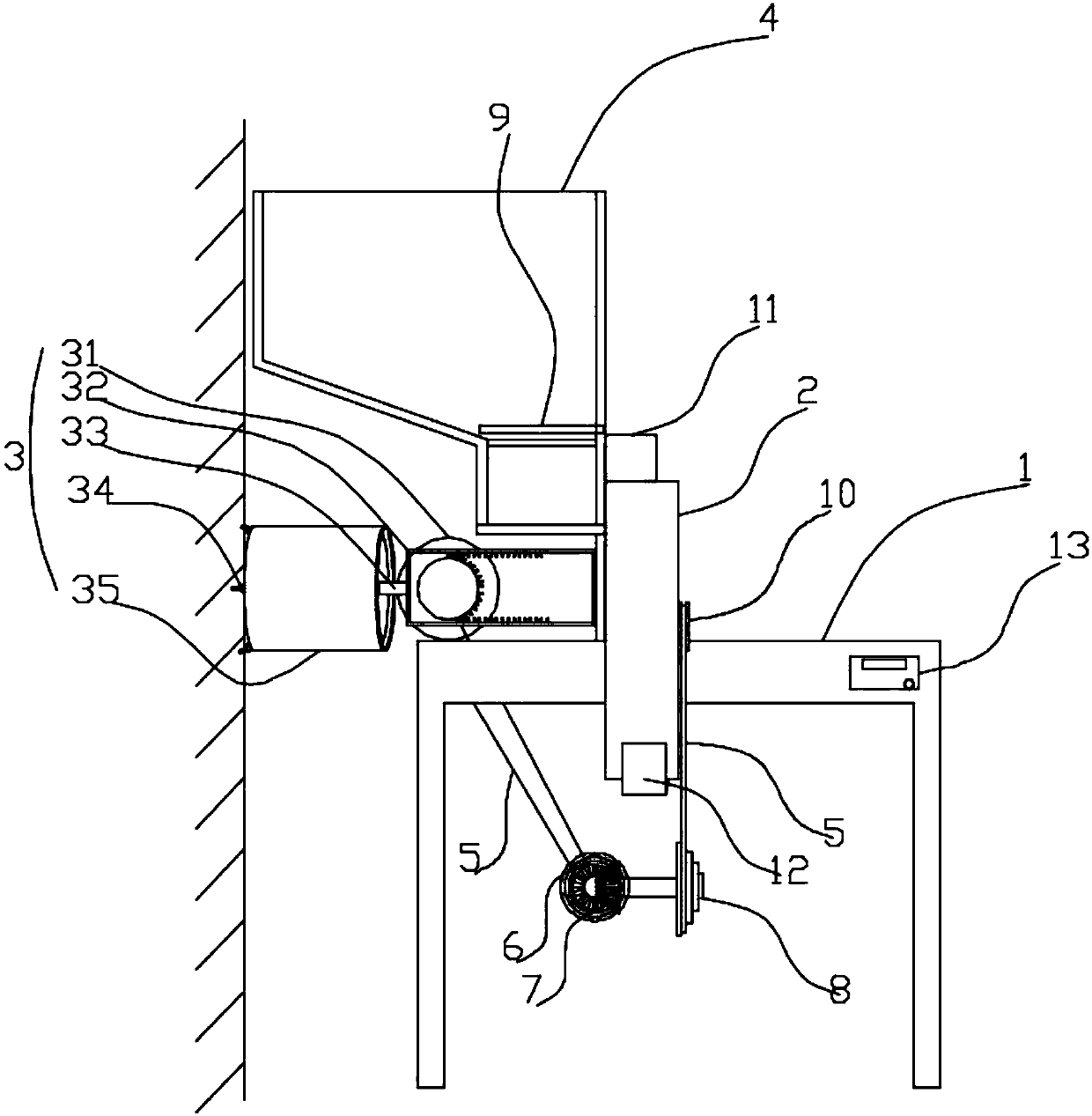

[0028] Such as figure 1 with figure 2 As shown, the present invention provides a device for slicing Chinese herbal medicines that automatically controls the slice thickness, including a frame 1, a slicing mechanism 2, a feeding mechanism 3 and a feed hopper 4, and the slicing mechanism 2 includes a cutterhead driving end 10 and a cutterhead , the feeding mechanism includes a pushing device 31 and a driving device, the driving device includes a toothed metal frame 32 and an incomplete gear shaft 33, the toothed metal frame 32 is sleeved on the outside of the incomplete gear shaft 33, and the toothed metal frame The frame 32 reciprocates left and right with the rotation of the incomplete gear shaft 33, the direction of the cutter head is perpendicular to the direction of motion of the driving device, and the driving end 10 of the cutter head and the incomplete gear shaft 33 are connected to the same center through the bevel gear steering mechanism 7. Drive motor, described bev...

Embodiment 2

[0032] Such as figure 1 with figure 2 As shown, the present invention provides a device for slicing Chinese herbal medicines that automatically controls the slice thickness. On the basis of Embodiment 1, the drive device also includes a limiting cavity housing 35, and one end of the limiting cavity housing 35 is provided with a fixed Bolt, the limiting cavity housing 35 has a limiting cavity 34, the end of the toothed metal frame 32 adjacent to the limiting cavity 34 is fixedly provided with a connecting rod, and the opening of the limiting cavity 34 is provided with an inner wall convex ring , and a slider is provided in the limiting cavity 34, and the slider is slidably connected with the inner wall of the limiting cavity 34, and one end of the slider is fixedly connected with the connecting rod. Working principle: the incomplete gear shaft 33 rotates to drive the toothed metal frame 32 to move left and right, the limit cavity shell 35 is horizontally fixed on the wall, an...

Embodiment 3

[0034] Such as figure 1 with figure 2 As shown, the present invention provides a device for slicing Chinese herbal medicines that automatically controls the slice thickness. On the basis of Embodiment 1, the drive device also includes a limiting cavity housing 35, and one end of the limiting cavity housing 35 is provided with a fixed Bolt, the limiting cavity housing 35 has a limiting cavity 34, the end of the toothed metal frame 32 adjacent to the limiting cavity 34 is fixedly provided with a connecting rod, and the opening of the limiting cavity 34 is provided with an inner wall convex ring , and a slider is provided in the limiting cavity 34, and the slider is slidably connected with the inner wall of the limiting cavity 34, and one end of the slider is fixedly connected with the connecting rod. Working principle: the incomplete gear shaft 33 rotates to drive the toothed metal frame 32 to move left and right, the limit cavity shell 35 is horizontally fixed on the wall, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com