SiOC composite negative electrode material for lithium ion battery and preparation method of SiOC composite negative electrode material

A technology for lithium ion batteries and negative electrode materials, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor cycle stability and high irreversible capacity of SiOC negative electrode materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Mix the solution of hydrogen-containing silicone oil, divinylbenzene and chloroplatinic acid (concentration: 11.3ppm) in a mass ratio of 6:3:1, and then crosslink at 120°C for 12h to synthesize solid polysiloxane alkyl;

[0031] (2) Ball mill the poplar wood chips after sieving, the ball milling time is 24 hours, the speed of rotation is 250r / min, the abrasive is taken out and dried, the treated wood powder is sieved and the particle size is less than 64 μm for later use; the poplar wood powder and polysilicon The oxane is ball milled at a mass ratio of 1:1 until uniformly mixed, the ball milling time is 12 hours, and the ball milling rate is 250r / min;

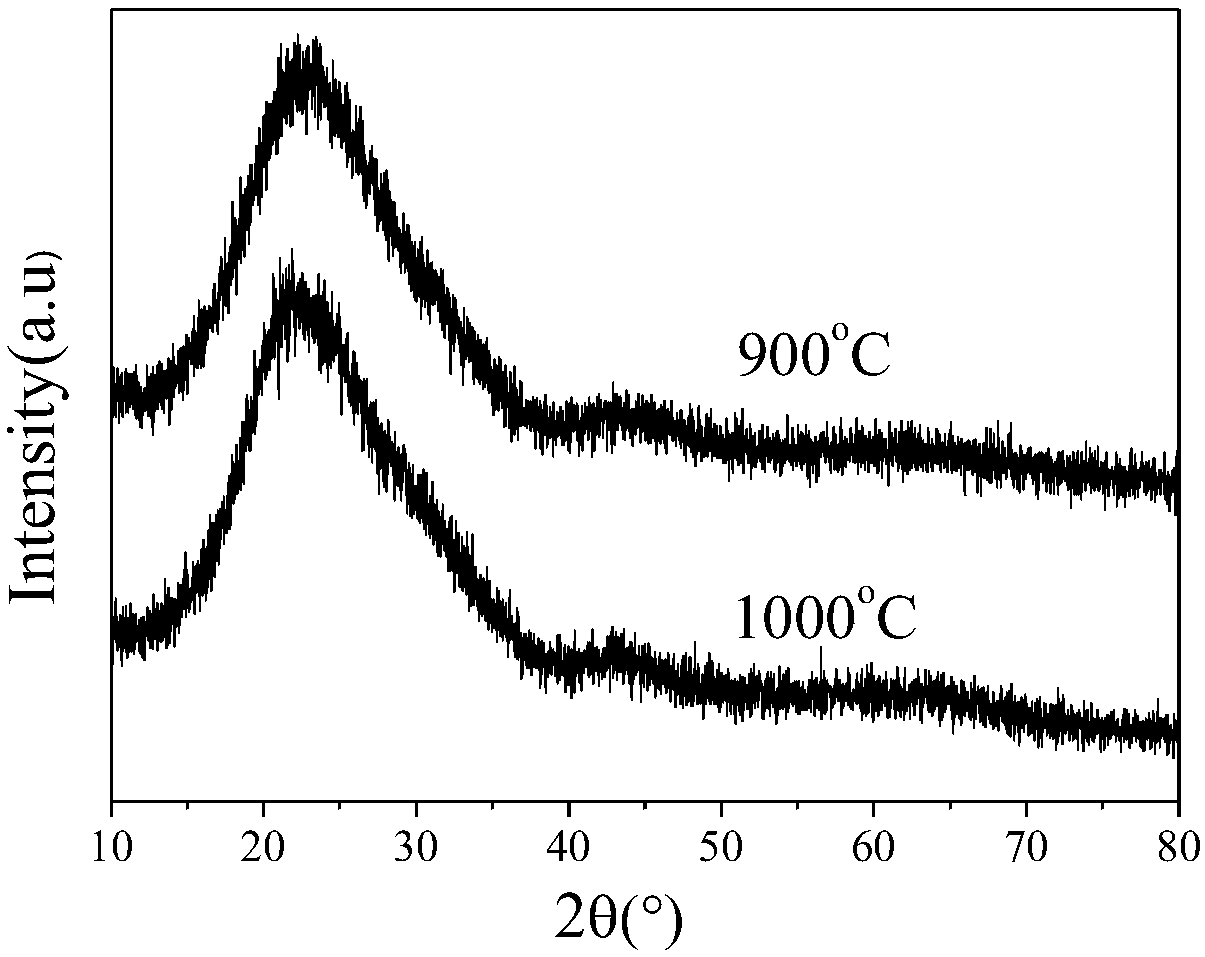

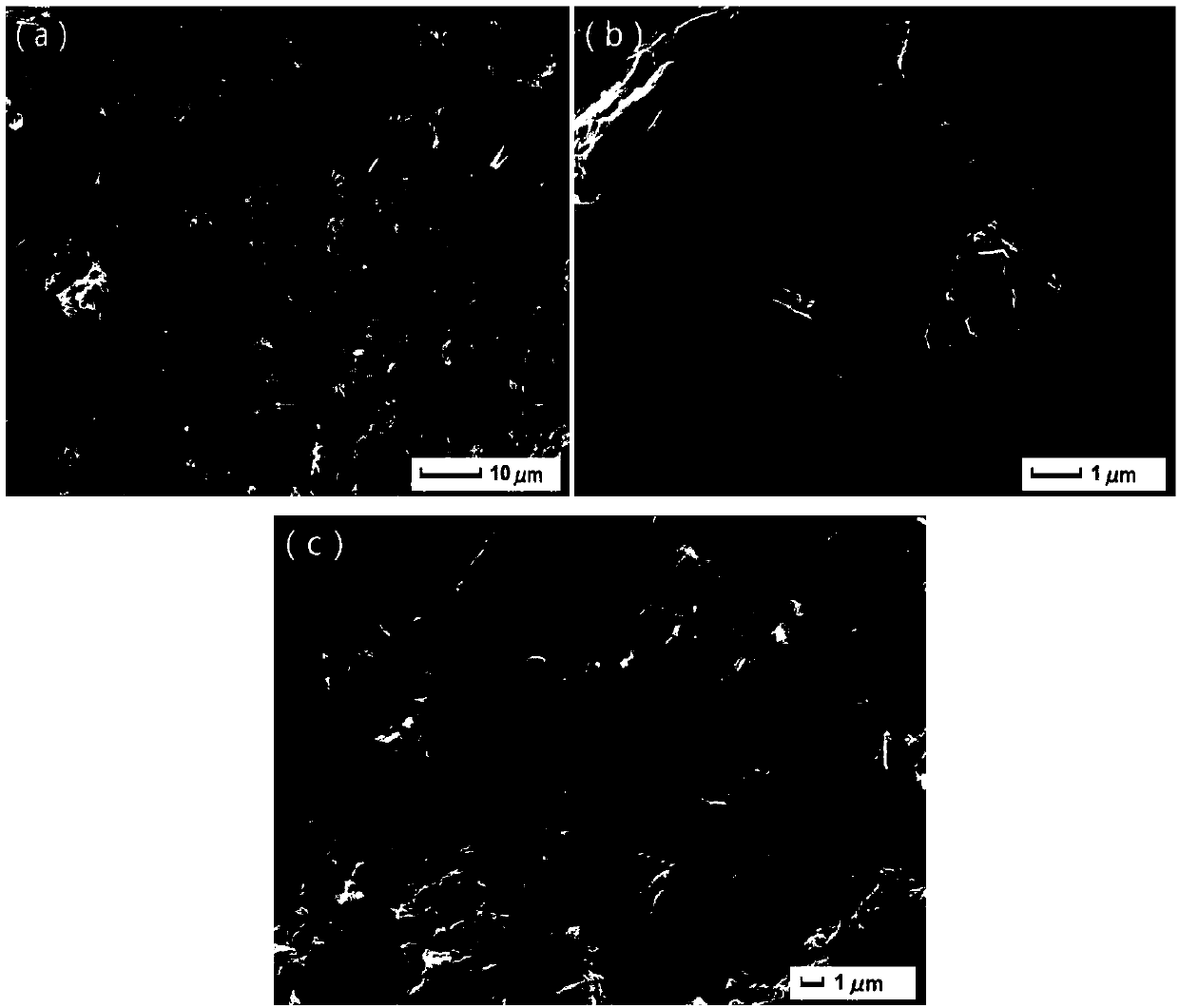

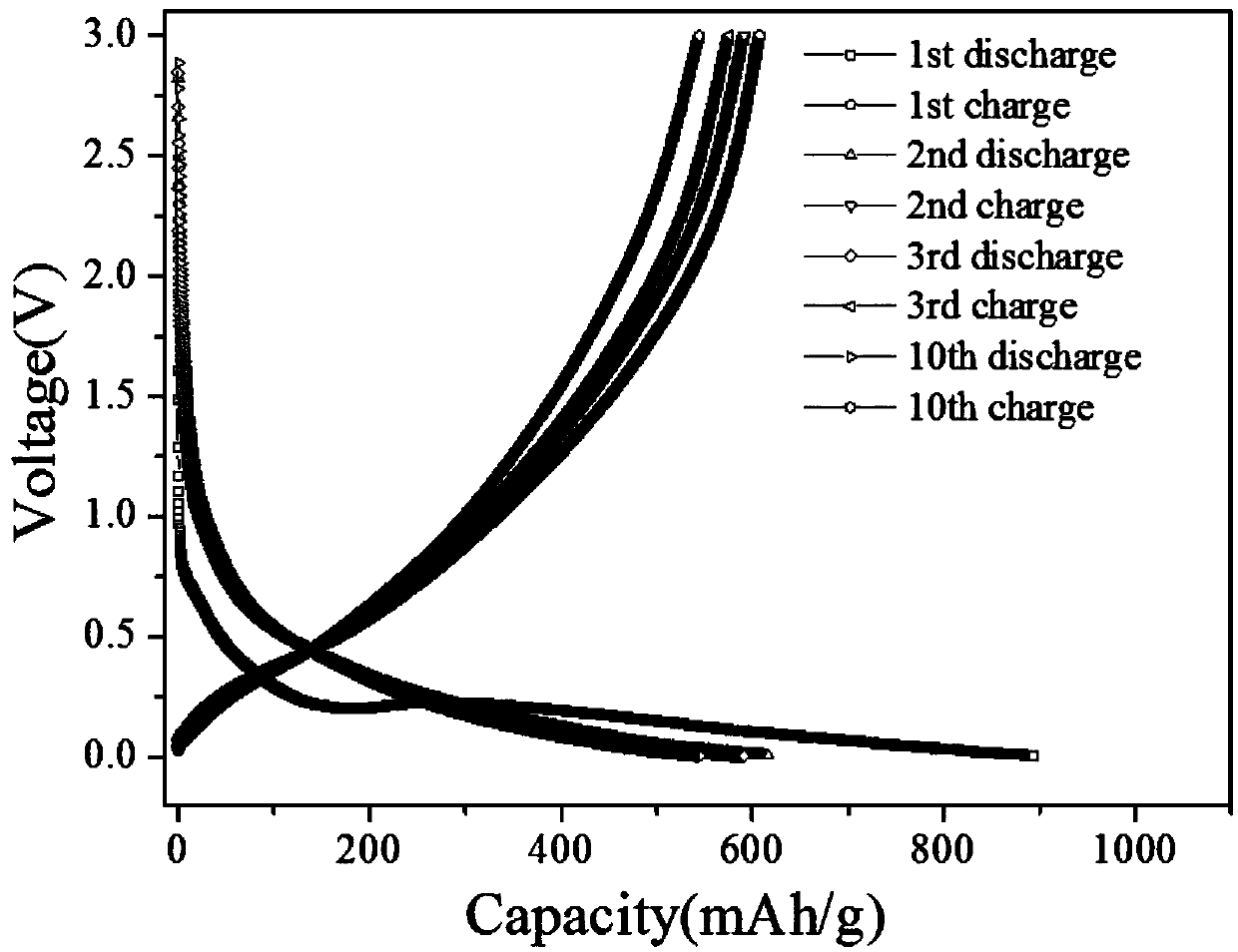

[0032] (3) Put the mixture of wood powder and polysiloxane in a tube furnace and sinter at high temperature under the protection of Ar gas. The speed is raised to 400°C, and the temperature is kept for 30 minutes; then the temperature is raised to 1000°C at a speed of 5°C / min, and the temperature is kept for 3 hour...

Embodiment 2

[0035] (1) Mix the solution of hydrogen-containing silicone oil, divinylbenzene and chloroplatinic acid (concentration: 11.3ppm) in a mass ratio of 6:3:1, and then crosslink at 120°C for 12h to synthesize solid polysiloxane alkyl;

[0036] (2) Ball mill the poplar wood chips after sieving, the ball milling time is 24 hours, the speed of rotation is 250r / min, the abrasive is taken out and dried, the treated wood powder is sieved and the particle size is less than 64 μm for later use; the poplar wood powder and polysilicon The oxane is ball milled at a mass ratio of 2:1 until uniformly mixed, the ball milling time is 12 hours, and the ball milling rate is 250r / min;

[0037] (3) Put the mixture of wood powder and polysiloxane in a tube furnace and sinter at high temperature under the protection of Ar gas. The speed is raised to 400°C, and the temperature is kept for 30 minutes; then the temperature is raised to 1000°C at a speed of 5°C / min, and the temperature is kept for 3 hour...

Embodiment 3

[0040] (1) Mix the solution of hydrogen-containing silicone oil, divinylbenzene and chloroplatinic acid (concentration: 11.3ppm) in a mass ratio of 6:3:1, and then crosslink at 120°C for 12h to synthesize solid polysiloxane alkyl;

[0041] (2) Ball mill the poplar wood chips after sieving, the ball milling time is 24 hours, the speed of rotation is 250r / min, the abrasive is taken out and dried, the treated wood powder is sieved and the particle size is less than 64 μm for later use; the poplar wood powder and polysilicon The oxane is ball milled at a mass ratio of 3:1 until uniformly mixed, the ball milling time is 12 hours, and the ball milling rate is 250r / min;

[0042] (3) Put the mixture of wood powder and polysiloxane in a tube furnace and sinter at high temperature under the protection of Ar gas. The speed is raised to 400°C, and the temperature is kept for 30 minutes; then the temperature is raised to 900°C at a speed of 5°C / min, and the temperature is kept for 3 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com