Ultrasonic detection device for live working insulating rod

A technology for ultrasonic testing and live work, which is used in measuring devices, analyzing solids using sonic/ultrasonic/infrasonic waves, and using sonic/ultrasonic/infrasonic waves for material analysis, etc. Safety of personnel and maintenance equipment, easy formation of delamination, air gaps, impurities and other problems, to achieve the effect of clear ultrasonic detection, clear ultrasonic detection, and reduction of ultrasonic clutter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

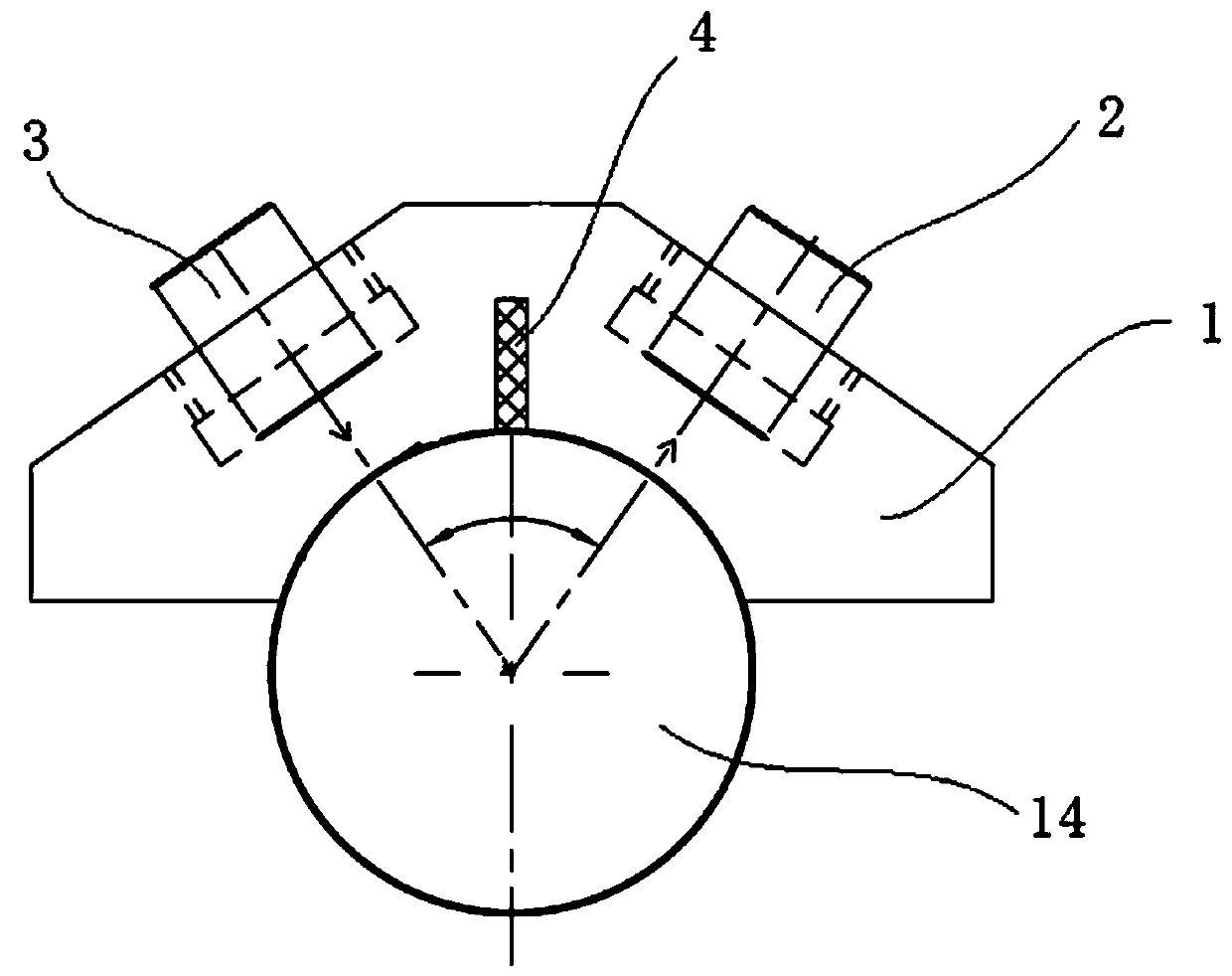

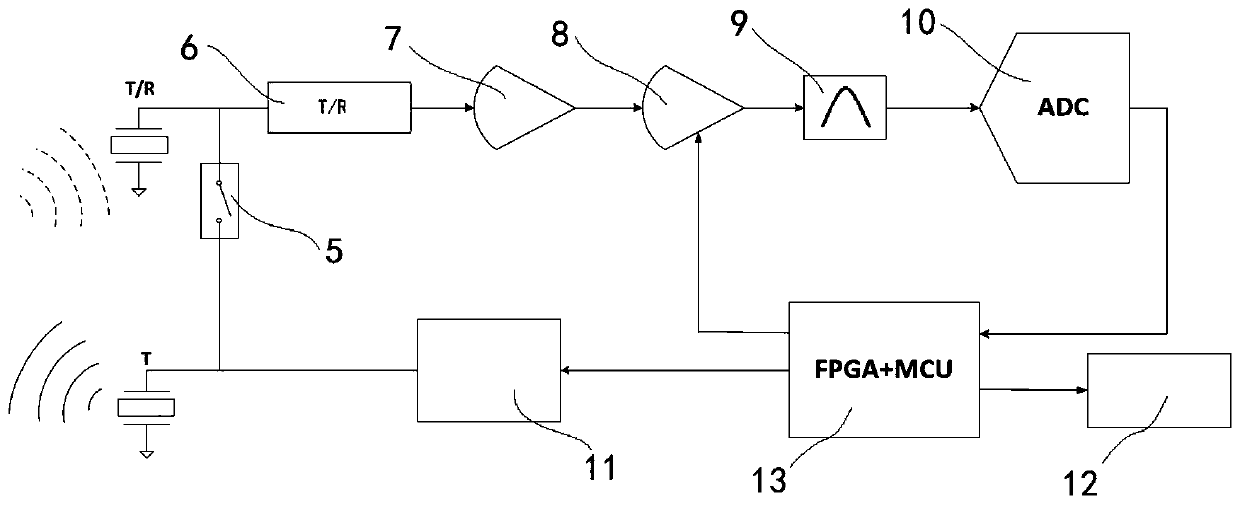

[0027] like Figure 1-2 As shown, an ultrasonic testing device for live working insulating rods includes a testing head and a testing instrument connected to the testing head. The testing head includes a wedge 1, a transmitting probe 3 and a receiving probe 2 arranged on the wedge 1; The wedge 1 between the transmitting probe 3 and the receiving probe 2 is provided with a sound insulation layer 4; the bottom surface of the wedge 1 is provided with a concave arc surface matched with the insulating rod, and the top surface of the wedge 1 is provided with a transmitting probe 3, The receiving probe 2; the transmitting probe 3 and the receiving probe 2 are facing the concave arc surface, and there is an angle between the transmitting probe 3 and the receiving probe 2; the transmitting probe 3 and the receiving probe 2 are connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com