Damping and supporting device of concrete pump pipe

A technology for concrete pump pipes and supporting devices, which can be used in pipeline supports, pipes/pipe joints/pipes, mechanical equipment, etc., and can solve problems such as high noise and affecting project quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

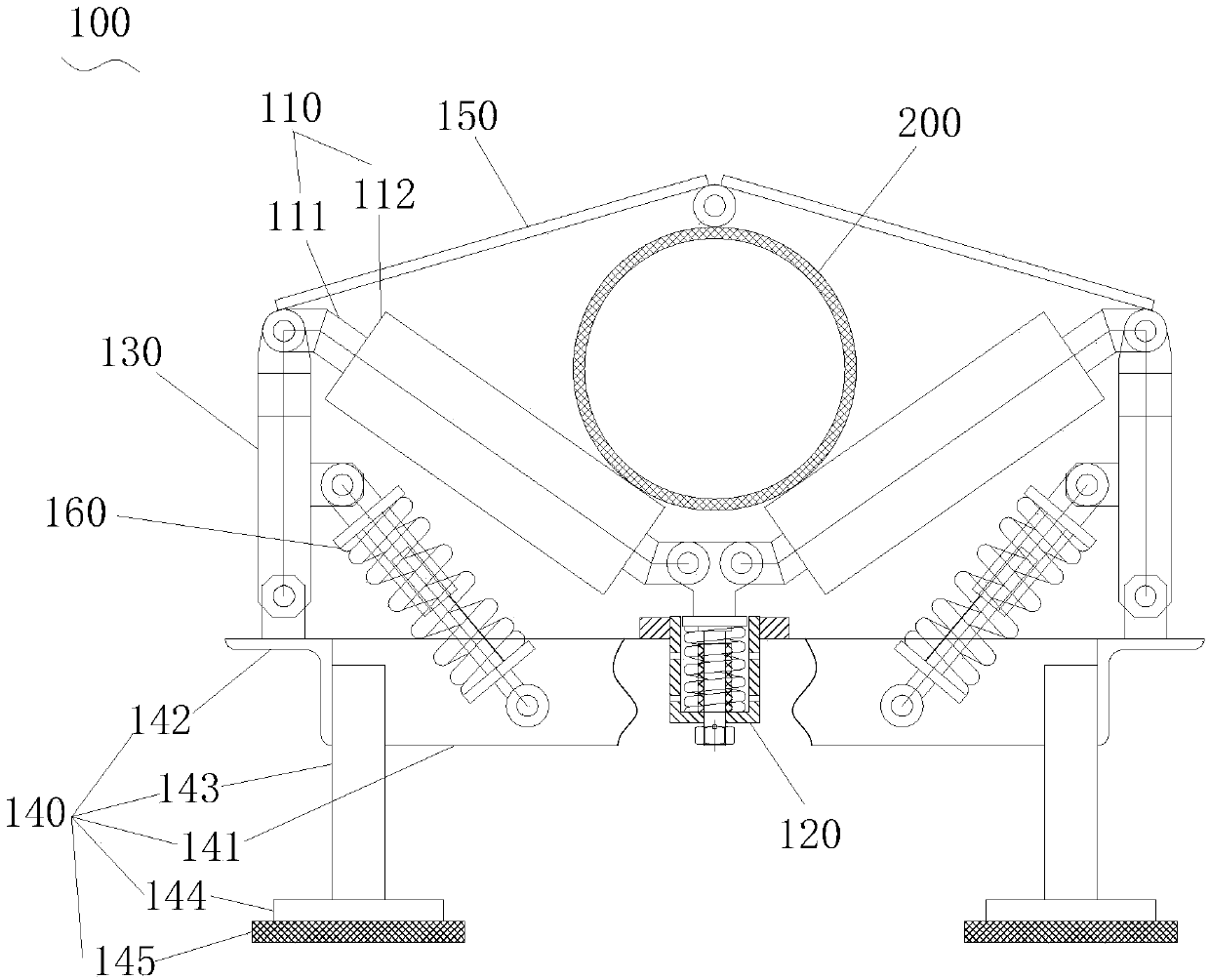

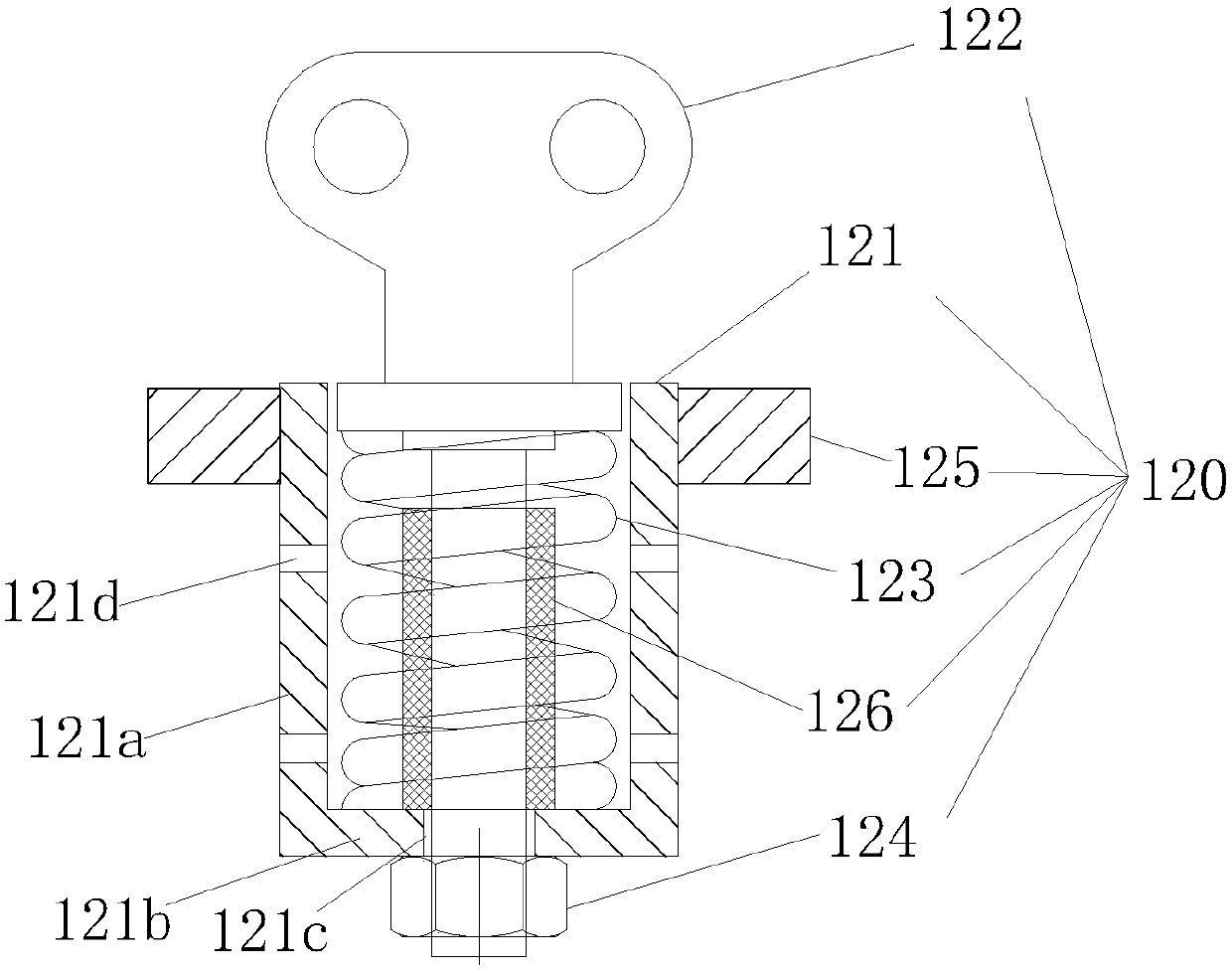

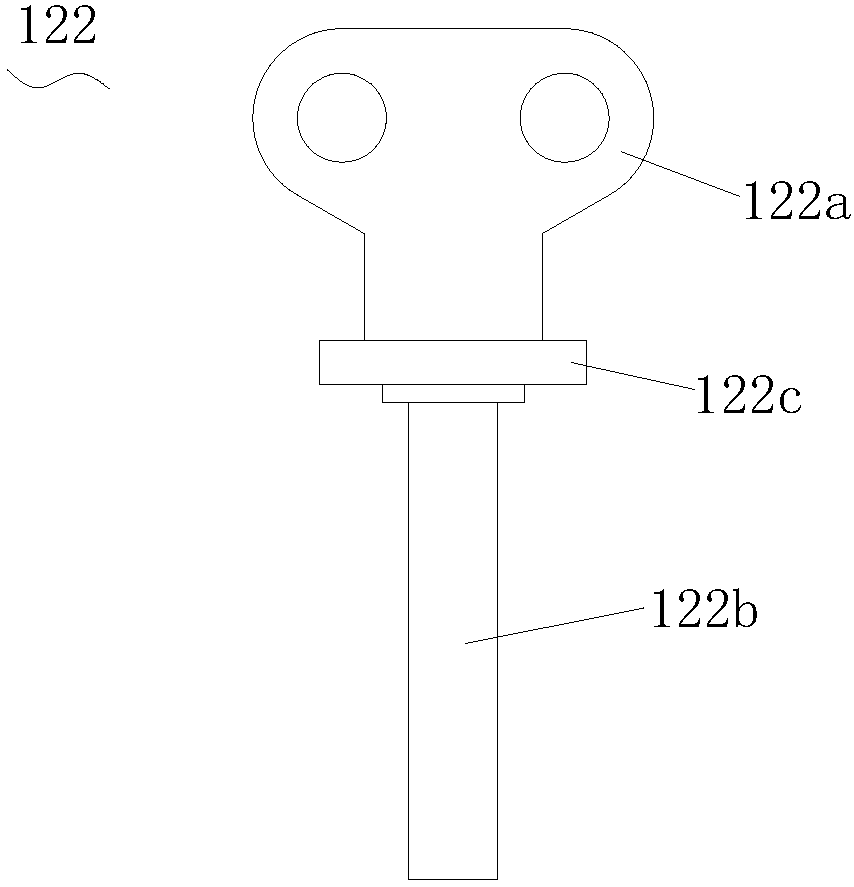

[0031] The concrete pump pipe shock-absorbing support device provided by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. The advantages and features of the present invention will become clearer with reference to the following description and claims. It should be noted that all the drawings are in a very simplified form and use imprecise scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

[0032] see Figure 1 to Figure 3 As shown, the following will combine Figure 1 to Figure 3 The gist of the present invention is further described.

[0033] Such as figure 1 As shown, a concrete pump pipe shock-absorbing support device 100 includes a V-shaped rolling support assembly 110 for supporting the pump pipe 200, a buffer spring assembly 120 whose top is hinged to the bottom of the V-shaped rolling support assembly 110...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com