Automobile damping and energy storage mechanism adapted for big impact force

A technology of automobile shock absorption and energy storage mechanism, applied in shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve the problems of ineffective identification, single function, and shortening the service life of shock absorbers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

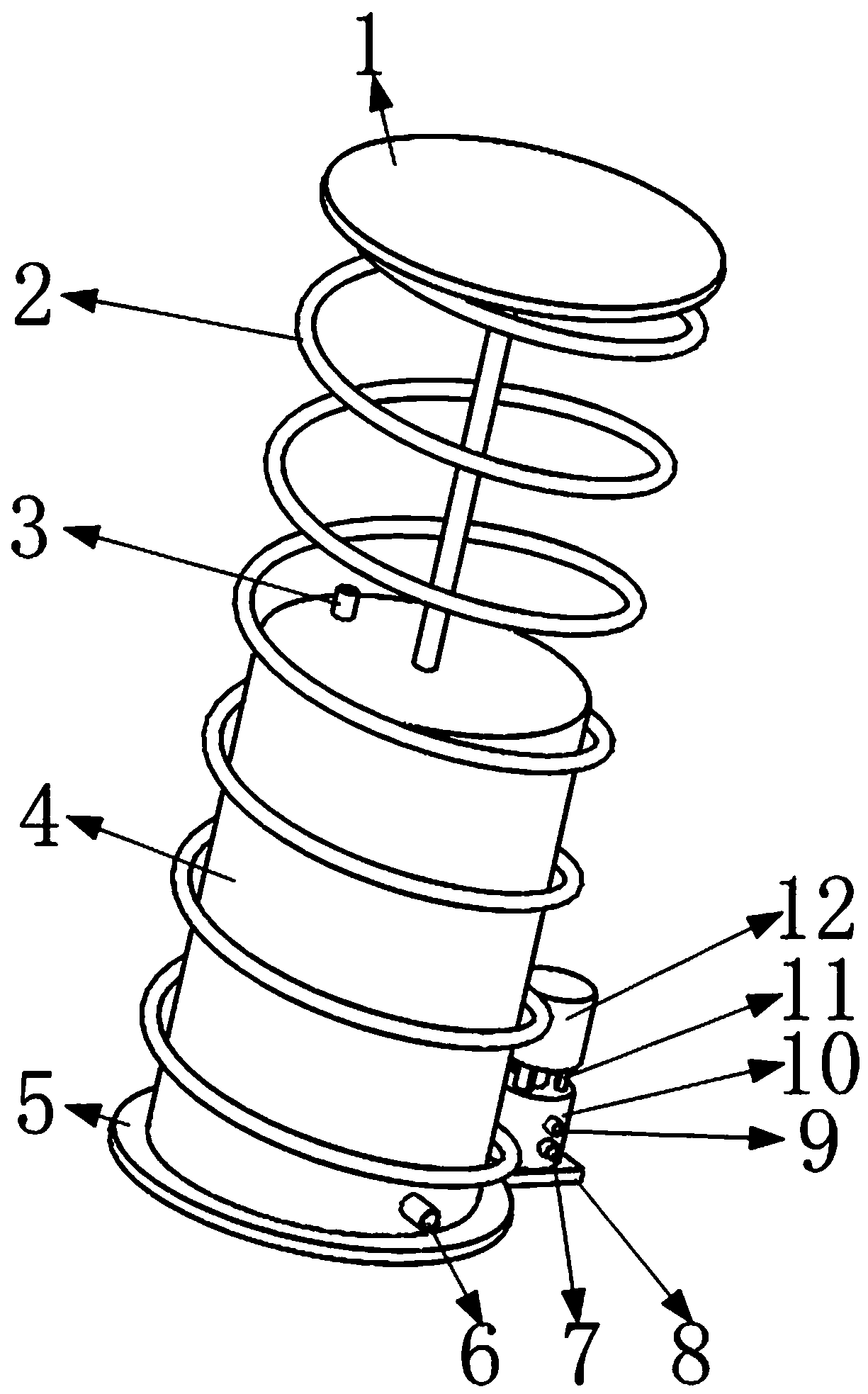

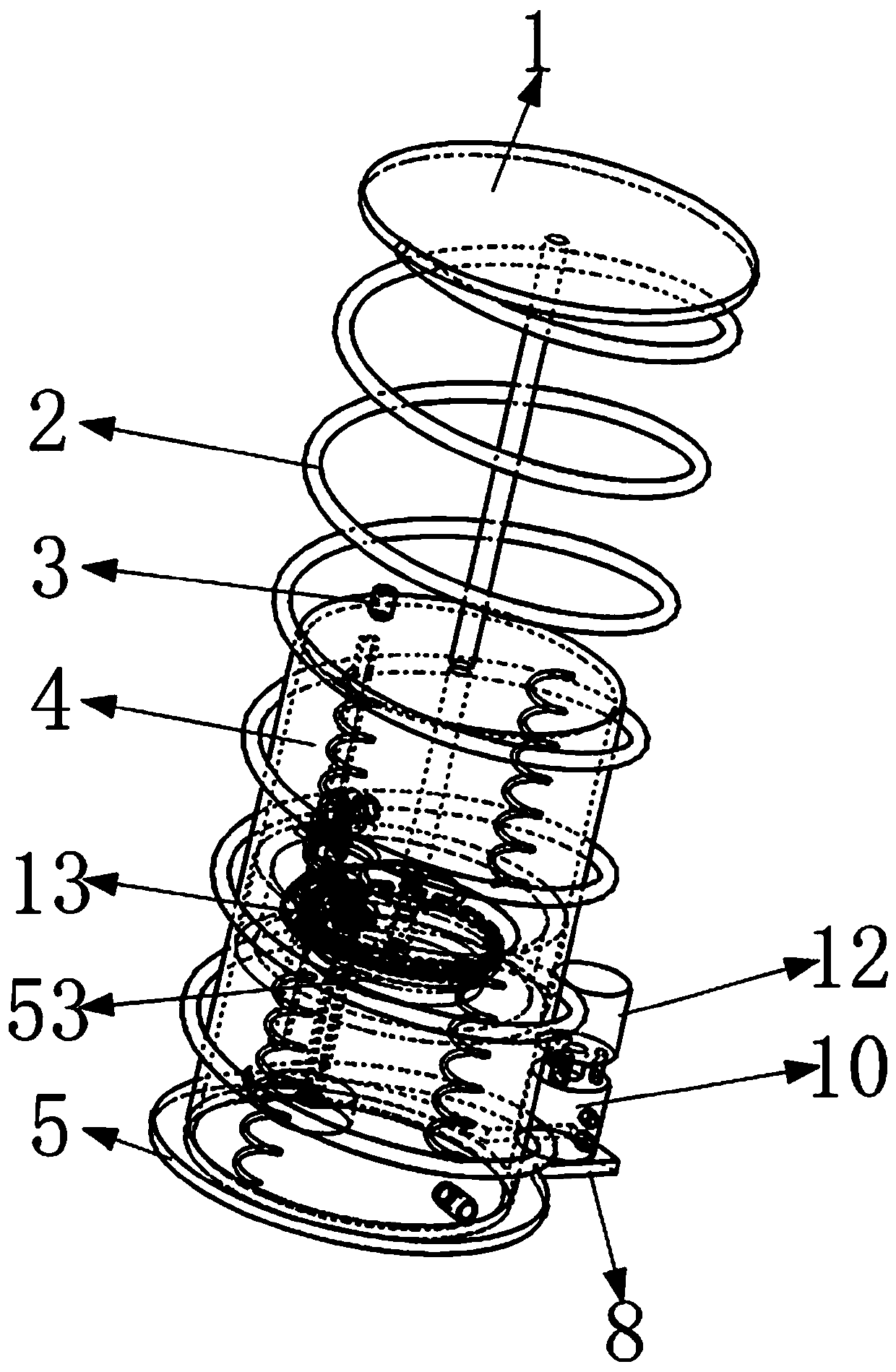

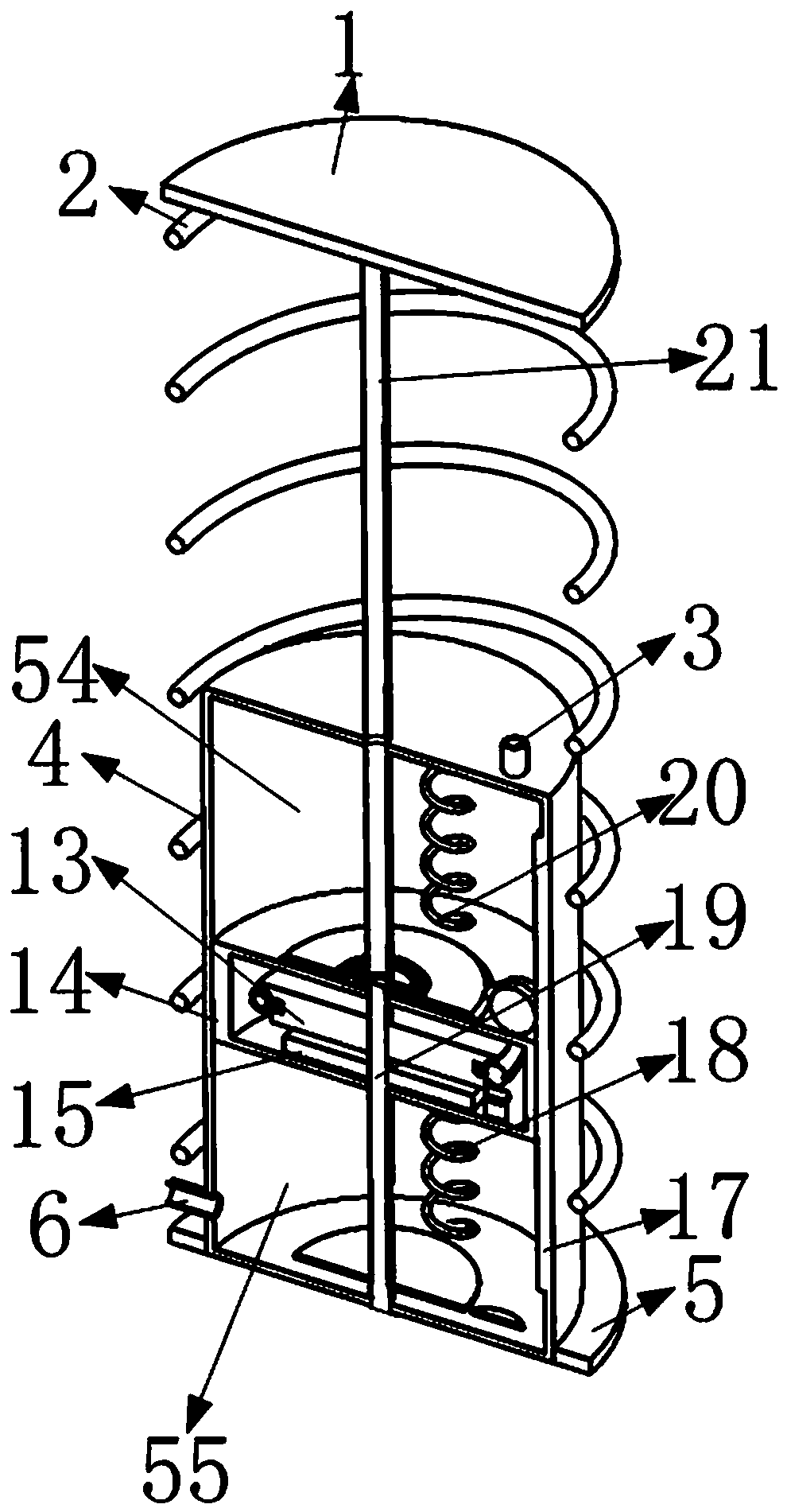

[0012] Such as figure 1 , 2 , 3, it includes a first baffle 1, a damping spring 2, a first nozzle 3, a damping shell 4, a second baffle 5, a second nozzle 6, a third nozzle 7, a fixed plate 8, First cavity 54, second cavity 55, fourth nozzle 9, air motor 10, support bar 11, generator 12, piston mechanism 53, first fixed block 16, rack 17, first spring 18, the first Two springs 20, push sleeve 21, first T-shaped ring groove 22, such as figure 1 As shown, wherein the second baffle plate 5 is installed on the outer circular surface of one end of the damping shell 4; one end of the fixed plate 8 is installed on the outer circular surface of the second baffle plate 5; as figure 1 As shown, one end of the air motor 10 is installed on the end face of the fixed plate 8; figure 1 As shown, the third nozzle 7 and the fourth nozzle 9 are installed on the air motor 10; as figure 1 As shown, the generator 12 is installed on the air motor 10 through three support bars 11 evenly distribu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com