Device for installing deep-water high-lift submersible sewage pump

A sewage pump and high-lift technology, which is applied to parts, pumps, and pump components of pumping devices used for elastic fluids, and can solve problems such as inability to play a limiting role, failure to use normally, and structural damage to the installation system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

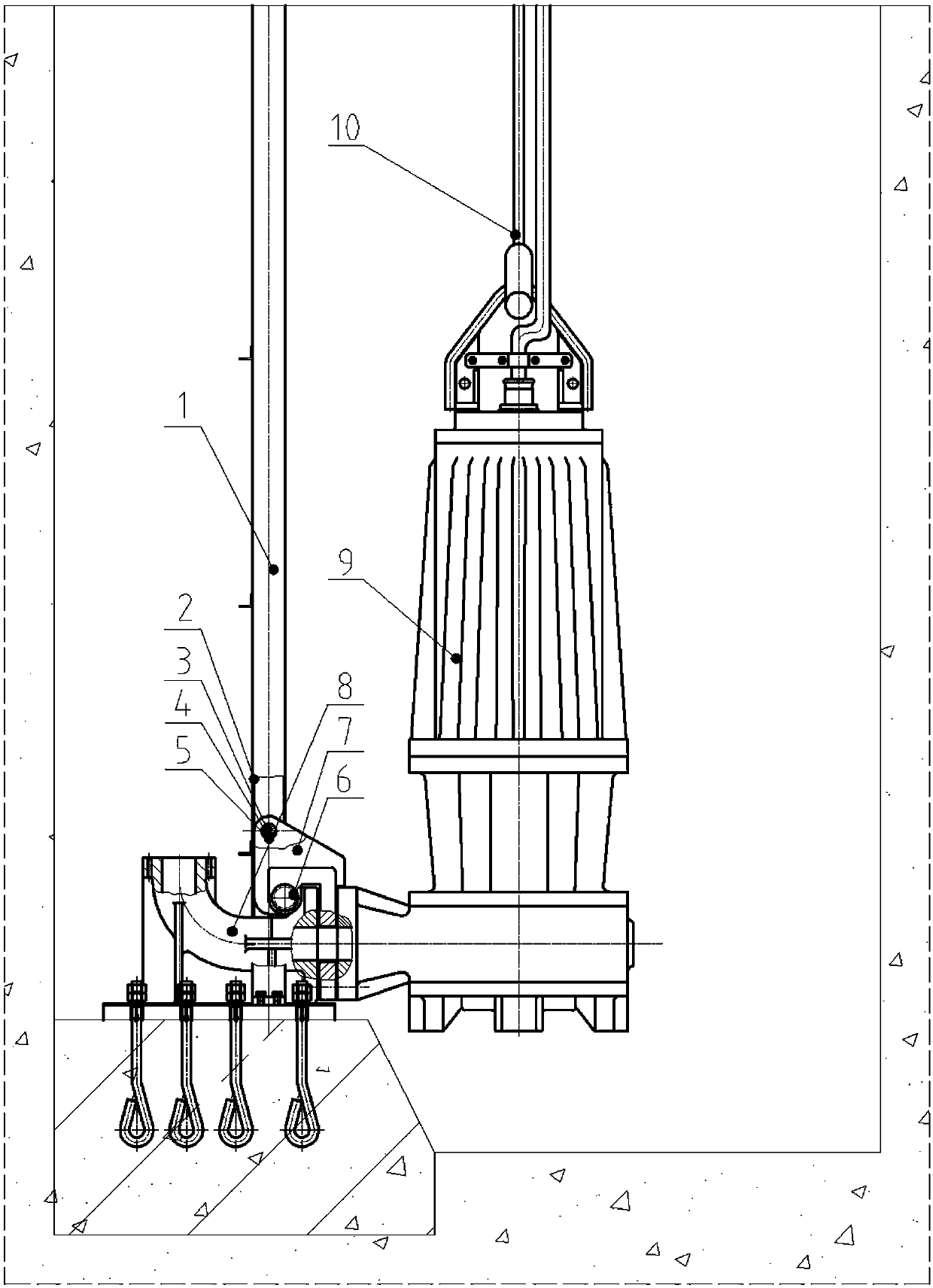

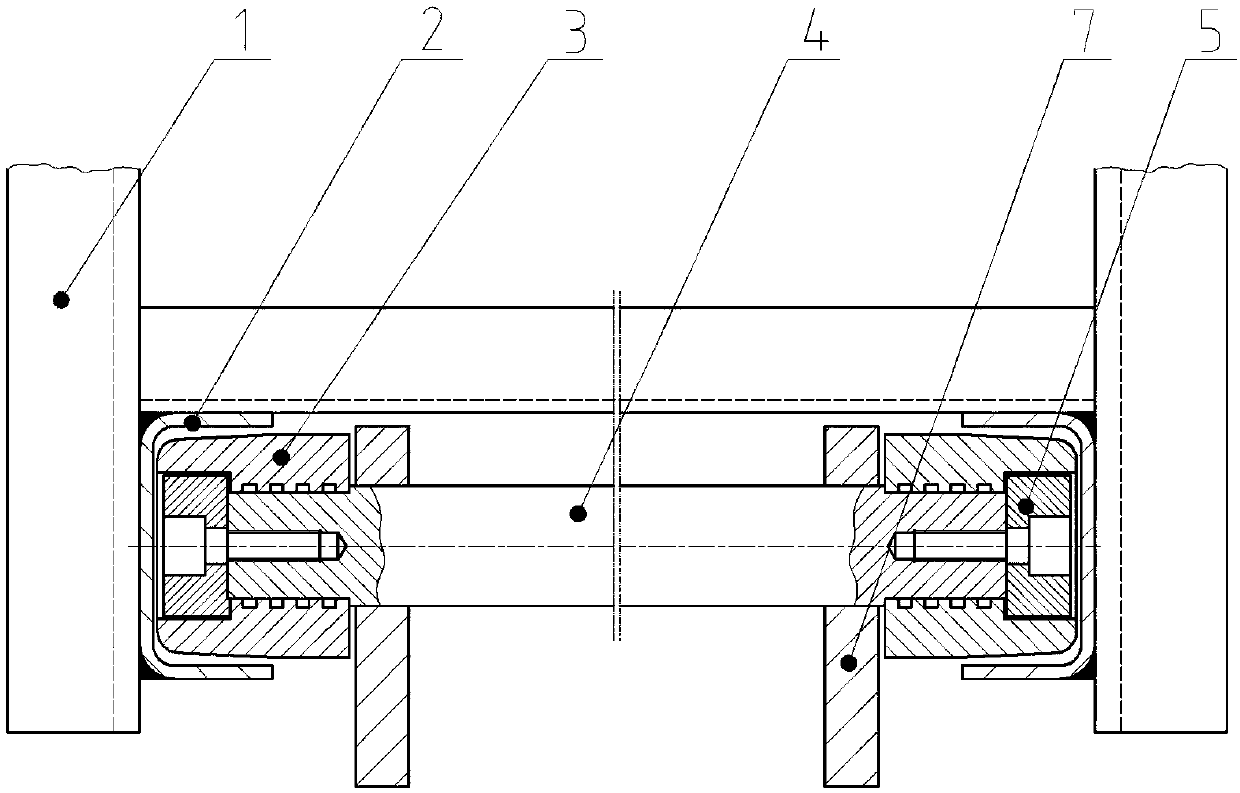

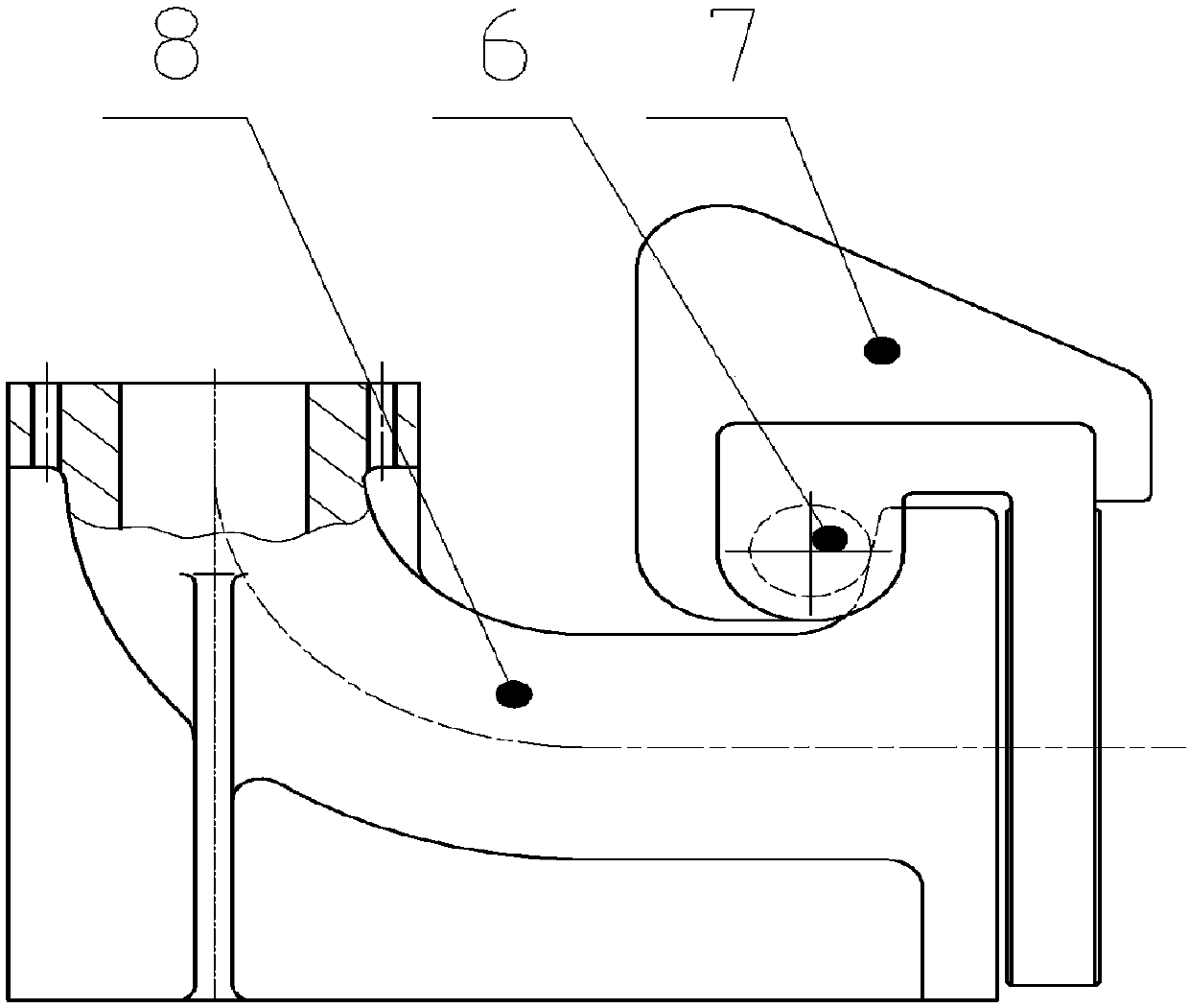

[0022] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] Such as Figure 1 to Figure 7 As shown, a device for installing a deep-water high-lift submersible sewage pump according to an embodiment of the present invention includes a guide rail 1 including a rail 2 , a roller 3 , a guide shaft 4 , a bracket 7 and a base 8 . The bottom end of the guide rail 1 is fixedly connected to the base 8 . There are two rails 2, and the two rails 2 are arranged oppositely. The roller 3 is located in the track 2, the roller 3 can move up and down along the track 2, and the gap between the roller 3 and the single side wall of the track 2 is less than 1mm. The guide shaft 4 is connected between the rollers 3 . The bracket 7 is fixedly connected with the guide shaft 4 .

[0024] When using the device with the above-mentioned structure to install the deep-water high-lift submersible sewage pump 9 , the dee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com