Gasket mechanism of engine oil cooler of engine and engine

An engine oil and cooler technology, applied in the direction of engine cooling, engine components, machines/engines, etc., can solve the problems of easy sliding, unfavorable assembly, and cannot be reused, achieve easy positioning and assembly, prevent gasket aging, Durability-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

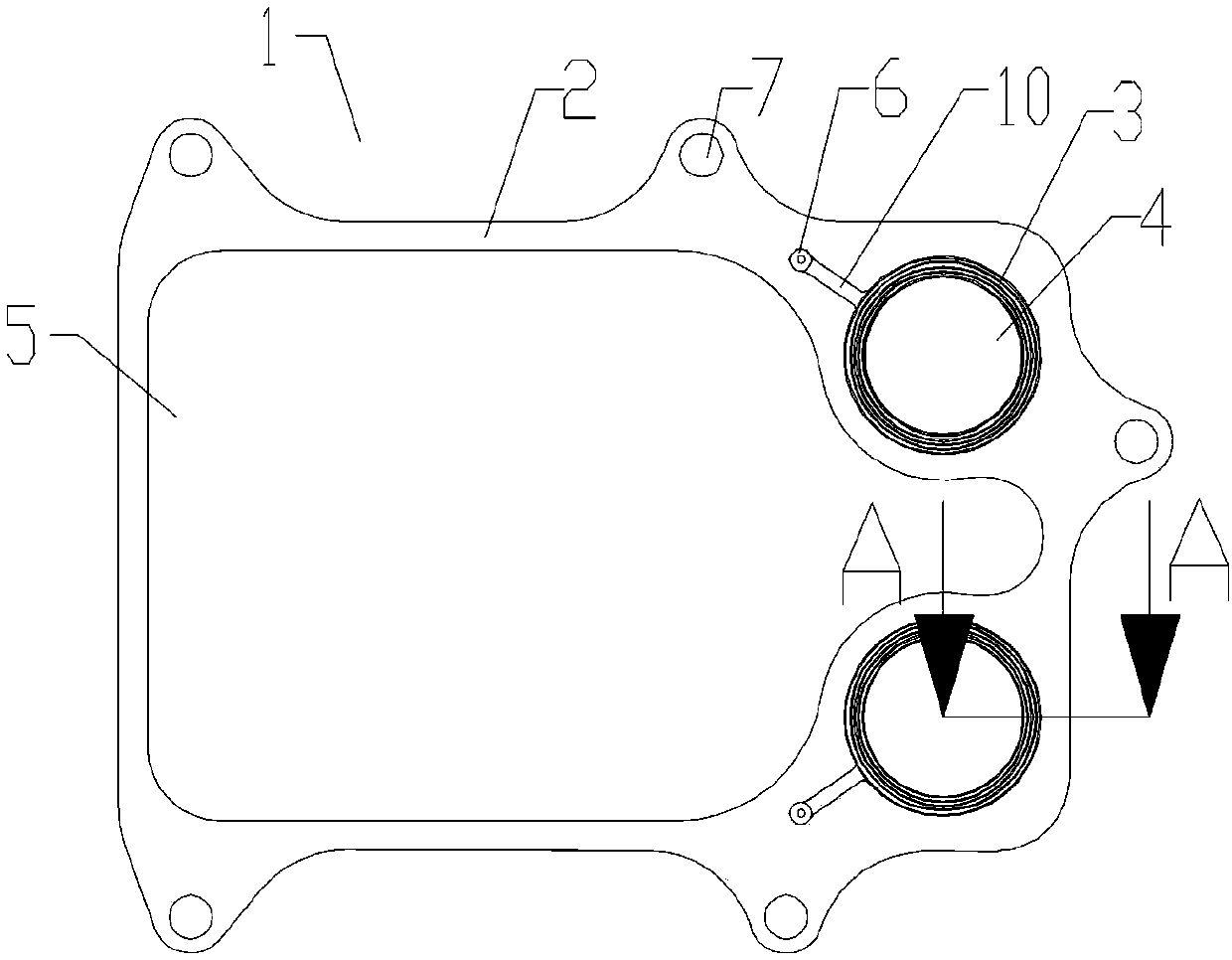

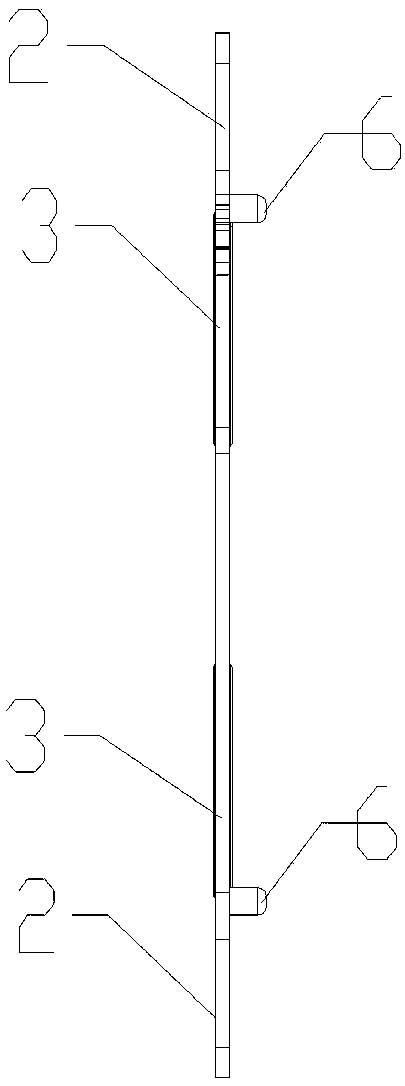

[0027] This embodiment provides an engine oil cooler gasket mechanism, such as Figure 1-2 As shown, it includes a metal gasket 2; what is important is that the gasket mechanism 1 also includes a rubber gasket 3, and the metal gasket 2 is made of light aluminum, and it is combined in a vulcanized manner. together; when installed, the rubber gasket 3 is close to the engine oil cooler, on the inside; the metal gasket 2 is away from the engine oil cooler, on the outside; the gasket mechanism 1 is protected by the engine oil When the cooler is compressed, the metal gasket 2 is used to limit the degree to which the inner rubber gasket 3 is compressed. Specifically, the metal gasket 2 can compress and limit the inner rubber gasket 3 to prevent the rubber gasket from The sheet 3 is in an excessively compressed state for a long time, and the compression uniformity of the rubber gasket 3 is ensured to ensure its sealing performance.

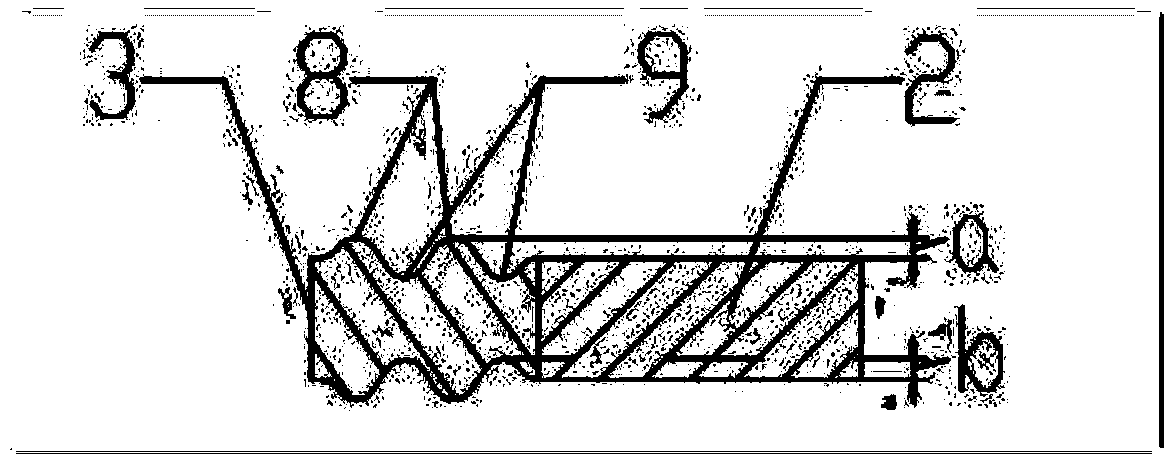

[0028] The metal gasket 2 is provided with a weigh...

Embodiment 2

[0038] This embodiment provides an engine that adopts the shim mechanism described in Embodiment 1. By adopting the gasket mechanism, the durability of the engine is strengthened and improved, and the utility model has a longer service life and wider applicability.

[0039] In summary, the gasket mechanism of the present invention adopts a sealing mode combining metal gaskets and rubber gaskets. This gasket structure has better sealing performance, can be reused, can prevent gaskets from aging and oil leakage, and has a long service life. ;Easy positioning and assembly during the assembly process, correspondingly, promoting the durability of the engine using the gasket mechanism to be enhanced.

[0040] In conclusion, the invention provides an engine oil cooler gasket mechanism with good sealing performance, reusable, long service life, and stable sealing performance for a sustained period of time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com