Component structure of water pump seal element as well as automatic manufacturing mechanism and method thereof

A technology of water pump sealing and component structure, applied in pump components, manufacturing tools, machines/engines, etc., can solve problems such as the improvement of viscose manufacturing technology, unstable manufacturing performance, and harsh environmental requirements, so as to increase manufacturing costs, Increase the effect of beautiful appearance, stable and reliable sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

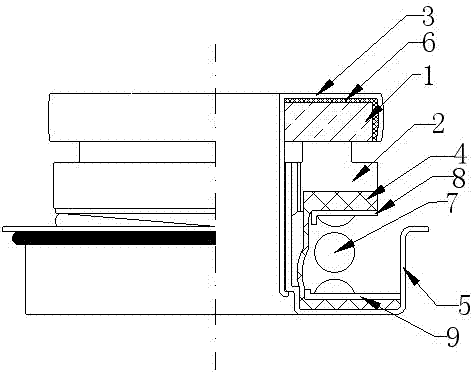

[0070] Such as figure 1 , 2 and 3, the structure of the water pump seal assembly of the present invention includes a moving ring 1, a static ring 2, a moving ring bushing 3, a rubber seal sleeve 4, a base cover 5, a moving ring 1 and a moving ring bushing 3 There is a moving ring sealing sleeve 6 between them, a rubber sealing sleeve 4 is set between the static ring 2 and the base sleeve 5, a spring 7 is set on the outer sleeve of the rubber sealing sleeve 4, and a washer 8 is provided between the top of the rubber sealing sleeve 4 and the spring 7 , the bottom of the rubber sealing sleeve 4 and the spring 7 are provided with a fixed seat reed 9, the outer circumference of the base cover 5 is symmetrically provided with 2 base cover cutouts 10, and the base cover middle hole 39 is symmetrically provided with 2 positioning ears 11, The outer circumference of the static ring 2 is symmetrically provided with 2 equal numbers of static ring cutouts 12 matched with the base cov...

Embodiment 2

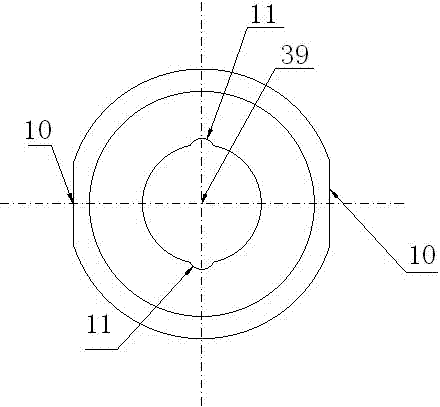

[0072] Such as figure 1 , 4 As shown in and 5, the water pump seal assembly structure of the present invention is provided with three base cover cutouts 10 along the circumferential direction of the base cover 5, and an angle of 120 degrees is formed between adjacent base cover cutouts 10, and along the middle hole of the base cover 39 are provided with three positioning ears 11 in the circumferential direction, and an included angle of 120 degrees is formed between adjacent positioning ears 11; along the circumferential direction of the static ring 2, there are three static ring notches 12 matched with the base sleeve notch 10 , along the circumferential direction of the inner hole 40 of the static ring, there are three positioning ear grooves 13 matched with the positioning ears 11 of the base cover 5, and an angle of 120 degrees is formed between adjacent static ring cutouts 12 and adjacent positioning ear grooves 13 . All the other structures are with embodiment 1.

Embodiment 3

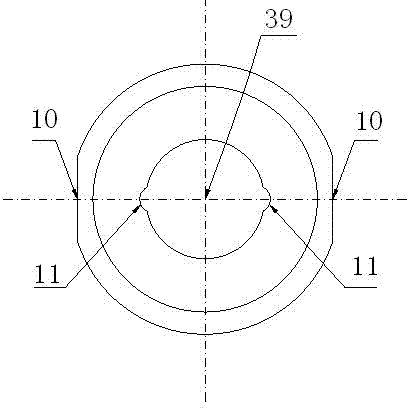

[0074] Such as figure 1 , 6 As shown in and 7, the water pump seal assembly structure of the present invention is provided with two base cover cutouts 10 along the circumferential direction of the base cover 5, and an angle of 60 degrees is formed between the two base cover cutouts 10, and along the middle hole of the base cover 39 is provided with two positioning ears 11 in the circumferential direction, and an included angle of 60 degrees is formed between the two positioning ears 11; along the circumferential direction of the static ring 2, there are two static ring notches 12 matched with the base sleeve notch 10 , an included angle of 60 degrees is formed between the two static ring cutouts 12, along the circumferential direction of the inner hole 40 of the static ring, there are two positioning ear slots 13 matching the positioning ears 11 of the base cover 5, two positioning ear slots 13 form an angle of 60 degrees. All the other structures are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com