A solidification and stabilization agent for remediation of beryllium-contaminated soil and sediments

A technology for contaminated soil and sediments, applied in the field of solidification and stabilization agents, can solve the problems of no beryllium-contaminated soil treatment cases, no special repair agents for beryllium-contaminated soil, etc., and achieve simple preparation and use methods, low cost, and reduced Effect of Leaching Concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The above-mentioned modified metakaolin can be prepared by the following method:

[0027] Weigh and mix metakaolin and calcium oxide at a mass ratio of 1:0.2 to 1:0.3, add water, control the liquid-solid mass ratio to 1 to 5, stir at a speed of 100 to 180r / min, and operate at 80°C to 100°C Hydrate for 6h-10h, then filter and dry to obtain modified metakaolin.

[0028] Compared with ordinary magnesium oxide, the particle size of activated magnesium oxide is finer, and the larger ratio of surface atoms to bulk atoms makes it have higher chemical activity and physical adsorption capacity, coupled with its own alkali properties, It can have a better adsorption effect on beryllium; preferably, 20-35 parts by mass of activated magnesium oxide; more preferably, 20-30 parts by mass of activated magnesium oxide.

[0029] Slag Portland cement is a hydraulic gel material made of Portland cement clinker, granulated blast furnace slag and appropriate amount of gypsum. Compared wit...

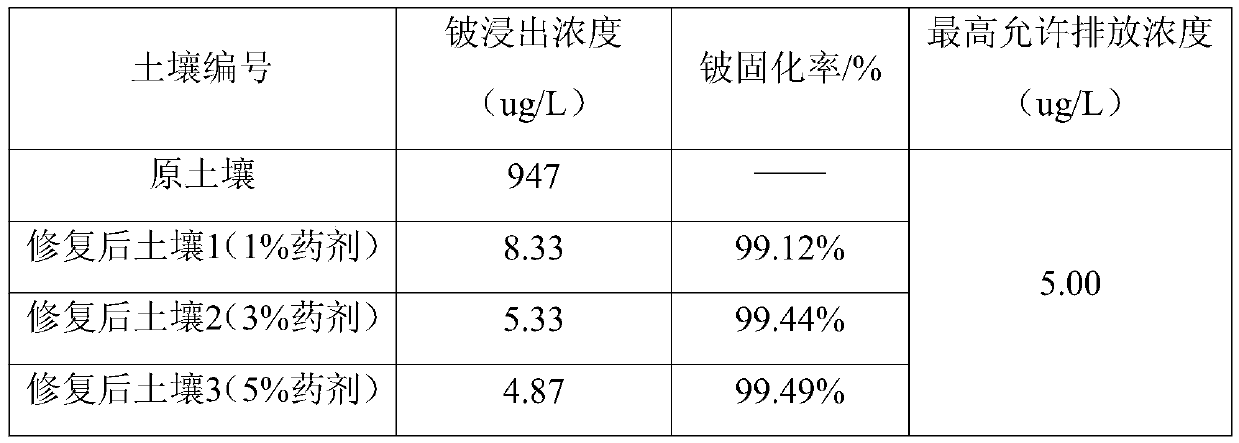

Embodiment 1

[0042] Preparation of modified metakaolin material: Weigh and mix metakaolin and calcium oxide at a mass ratio of 1:0.2, add water at a liquid-solid mass ratio of 2, and mature at 95°C for 8 hours. During this period, control the reaction stirring speed After the reaction is completed, filter and dry to obtain modified metakaolin.

[0043] The preparation of the curing and stabilizing agent in this embodiment is as follows: uniformly mix 40 parts by mass of modified metakaolin, 20 parts by mass of activated magnesium oxide and 40 parts by mass of slag Portland cement to obtain the compound for repairing beryllium-contaminated soil and sediments. Solidified Stabilizer.

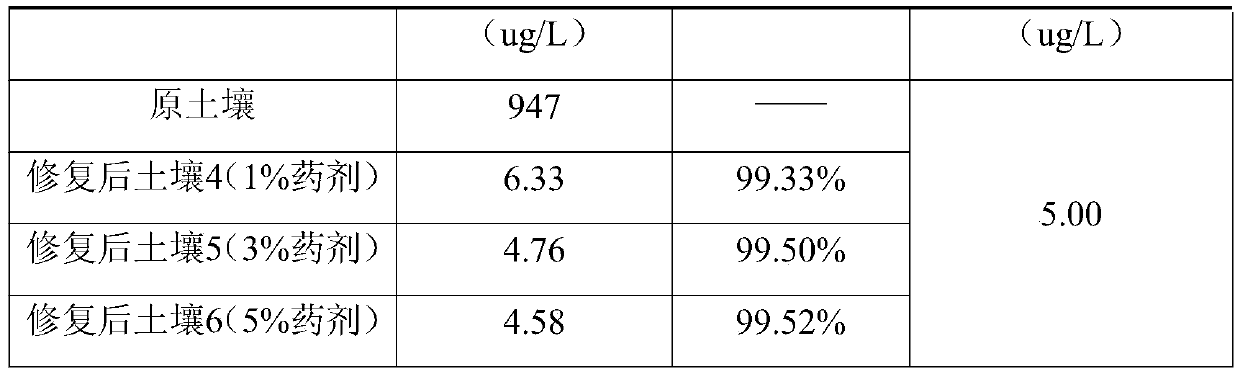

Embodiment 2

[0045] Preparation of modified metakaolin material: Weigh and mix metakaolin and calcium oxide at a mass ratio of 1:0.3, add water at a liquid-solid mass ratio of 2, and hydrate at 95°C for 8 hours. During this period, the hydration reaction is controlled The stirring speed is 120r / min. After the reaction is completed, filter and dry to obtain the modified metakaolin.

[0046] The preparation of the curing and stabilizing agent in this embodiment is as follows: uniformly mix 30 parts by mass of modified metakaolin, 30 parts by mass of activated magnesium oxide and 40 parts by mass of slag portland cement to obtain a compound for repairing beryllium-contaminated soil and sediments. Solidified Stabilizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com