High-voltage wiring box convenient to assemble and disassemble and assembling and disassembling method of high-voltage wiring box

A high-voltage wiring and easy-to-install technology, which is applied to electrical devices, transportation and packaging, electric vehicles, etc., can solve problems such as electric shock, equipment damage, and inconvenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with accompanying drawing:

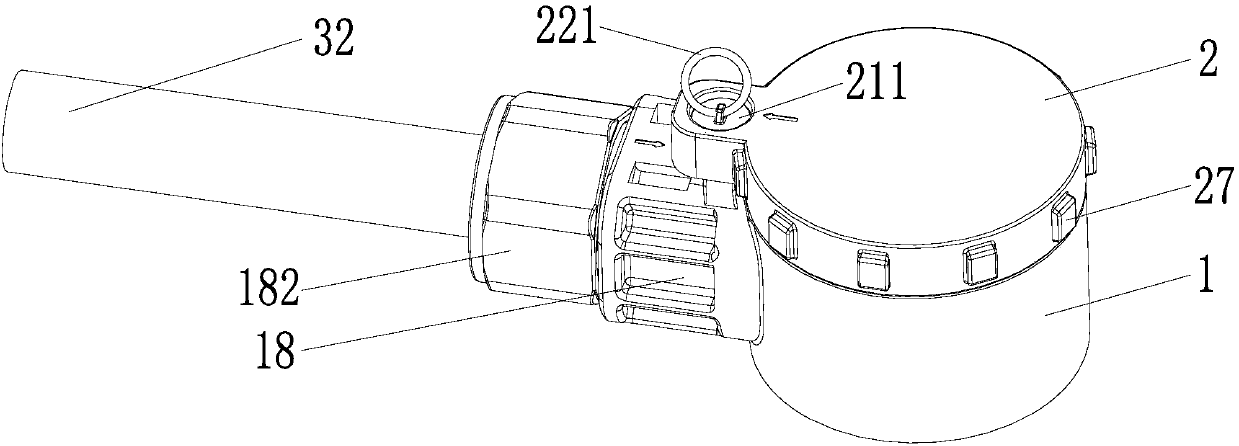

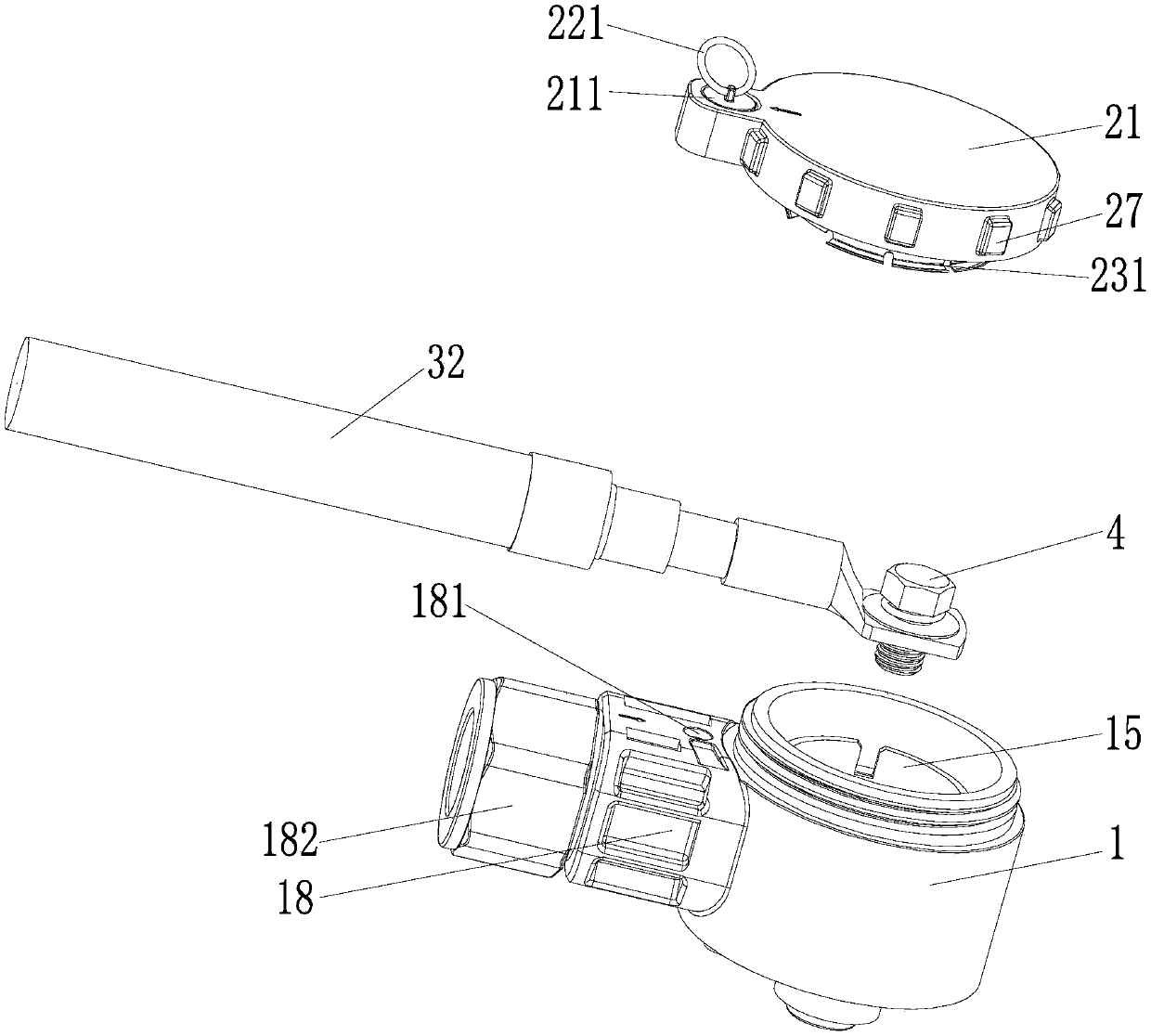

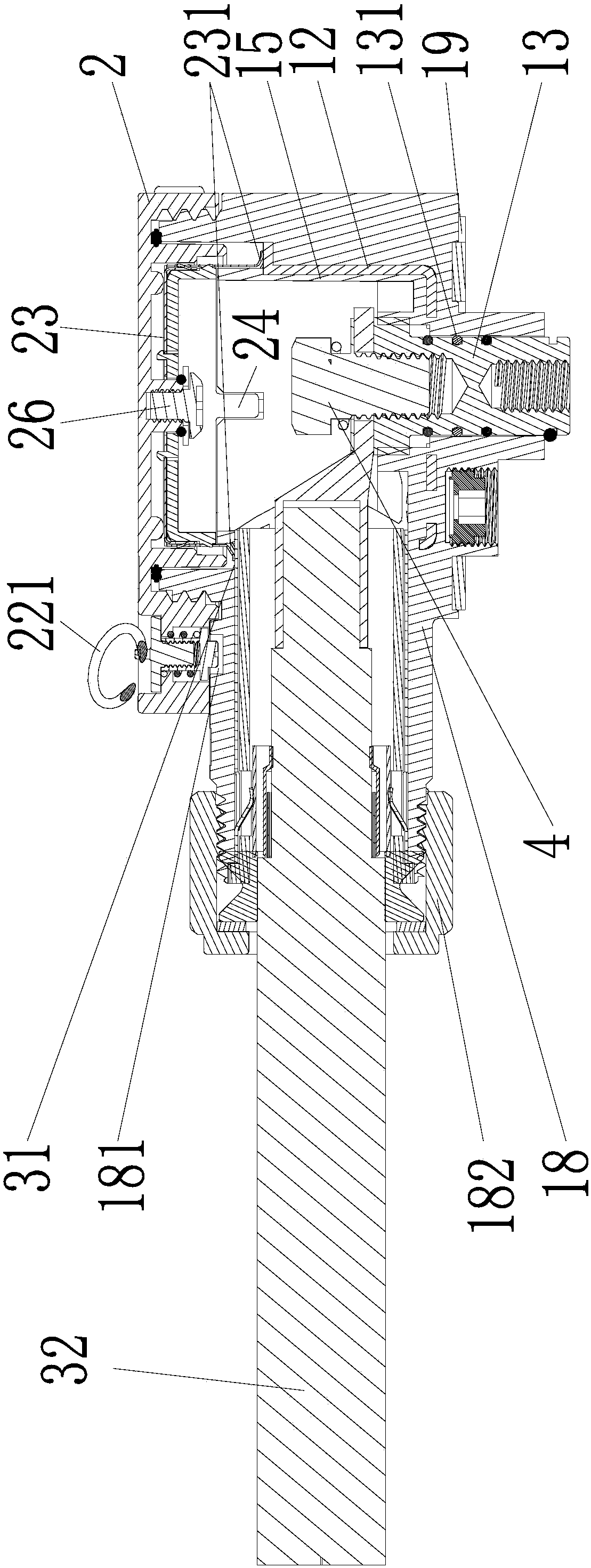

[0028] see Figure 1 to Figure 3 As shown, the high-voltage junction box that is convenient to install and disassemble includes a base 1, an upper cover 2 connected to the base 1, the base 1 is installed on the panel of the equipment, and the wire harness 32 enters the inner cavity of the base 1 after passing through the gland 18 , and connected to the terminal post 13 located in the inner cavity of the base 1 through the connecting screw 4, the upper cover 2 is detachably connected to the base 1, the radial protrusion of the upper cover 2 is provided with a stop lock 22, and the base 1 The corresponding recess is provided with a stop groove 181. When the upper cover 2 is screwed to the set position, the stop lock 22 of the upper cover 2 slides into the stop groove 181 of the base to lock, and the upper cover 2 cannot be twisted any more. When it needs to be disa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com