Prefabricated box girder square steel pipe core die

A square steel pipe and mandrel technology, which is applied in the direction of manufacturing tools, ceramic molding cores, ceramic molding mandrels, etc., can solve the problems of difficult installation of the mandrel, low overall rigidity and strength, and difficult disassembly, so as to achieve convenient support and disassembly. Assembly and disassembly, easy to disassemble effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with accompanying drawing and specific embodiment, and present embodiment is based on the premise of technical scheme of the present invention, has provided detailed implementation and specific operation process, but protection scope of the present invention is not limited to following implementation example.

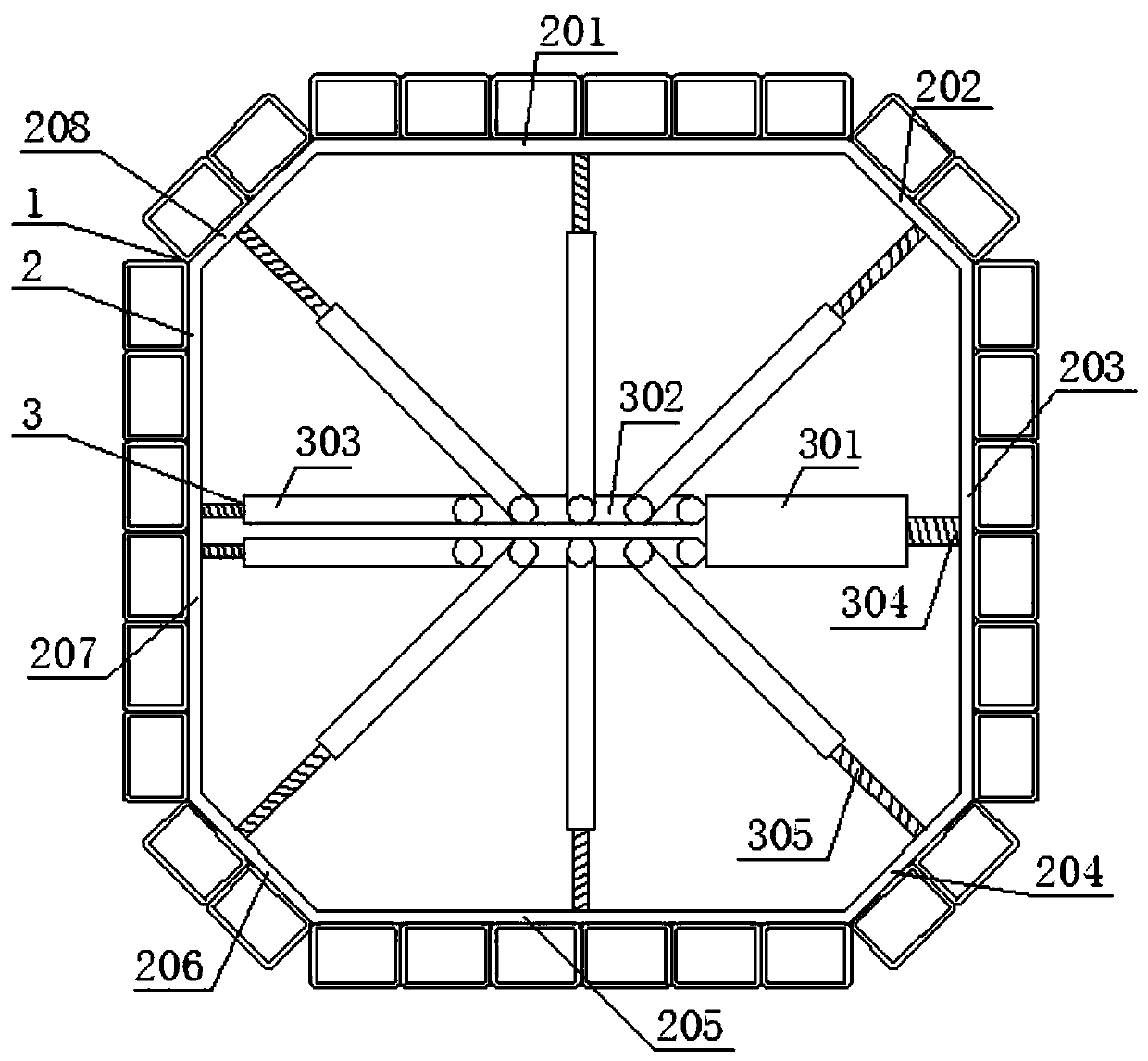

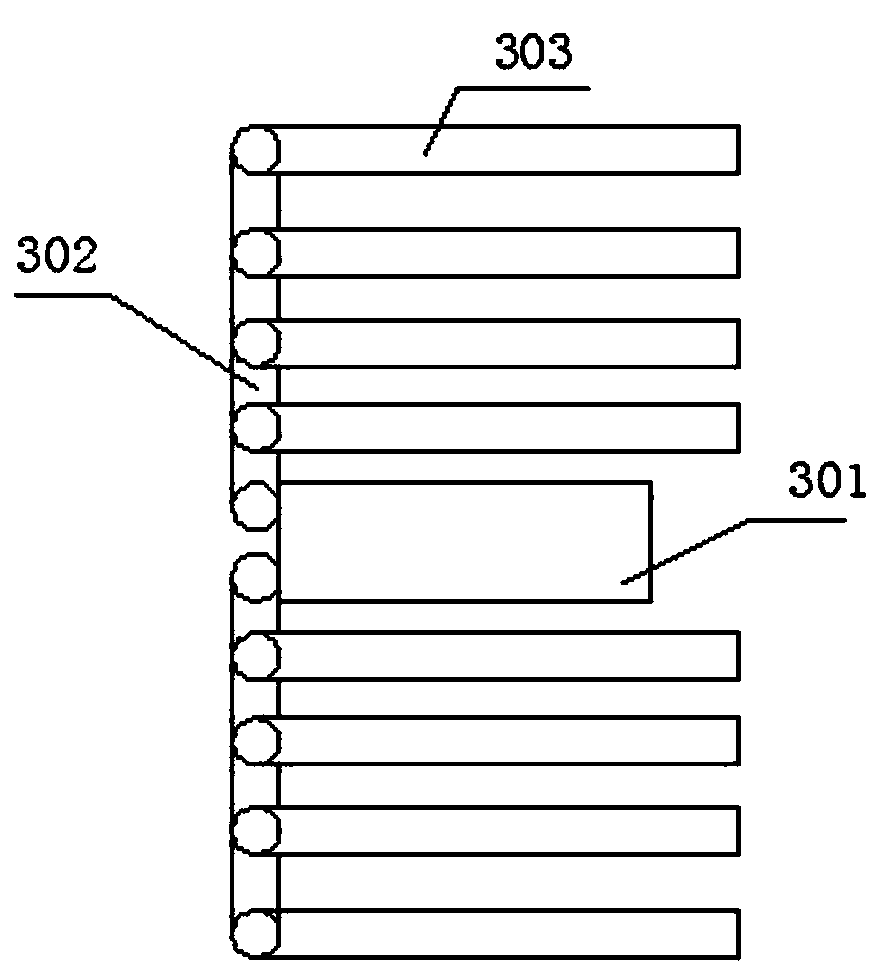

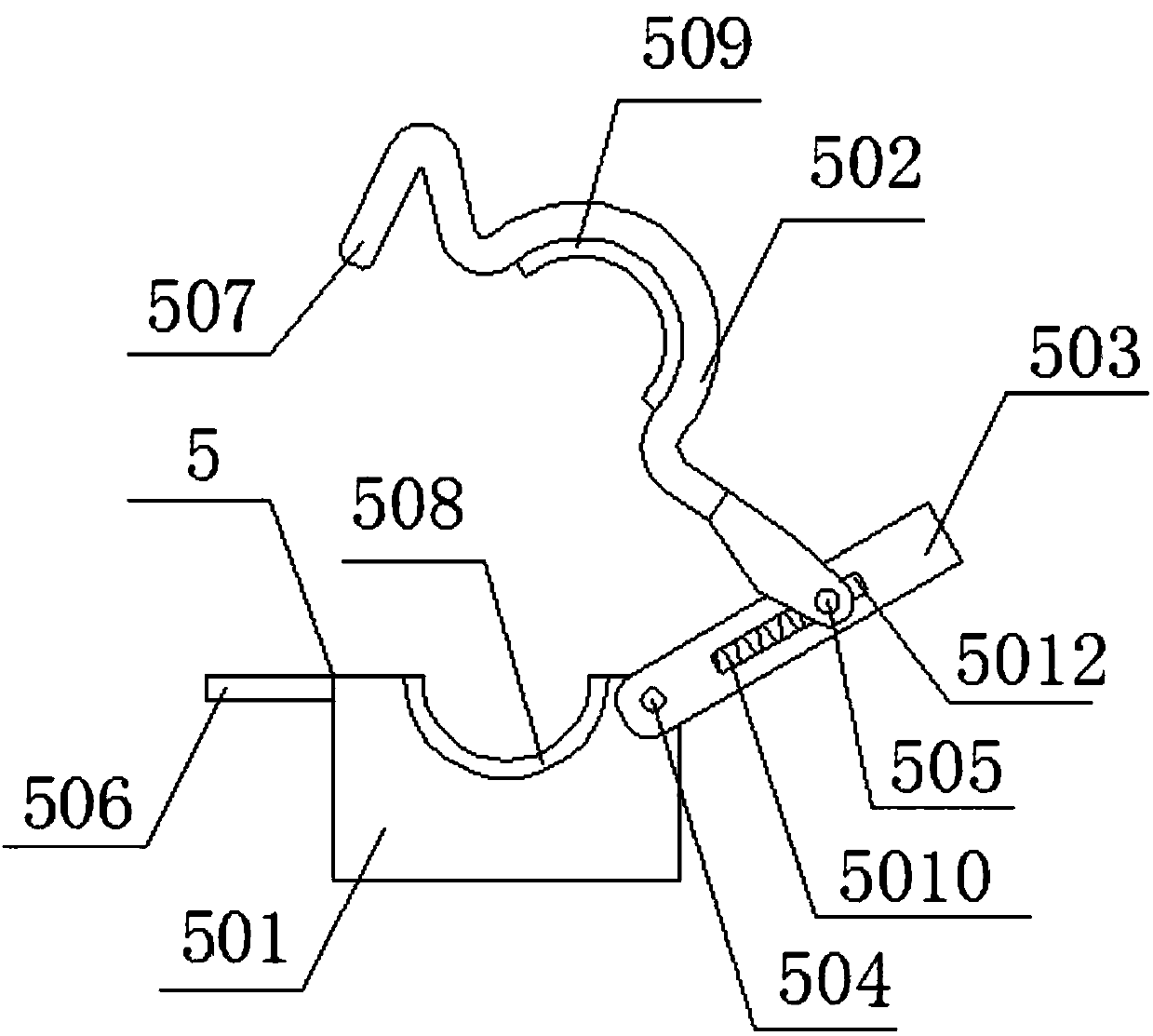

[0028] As shown in the figure, a prefabricated box girder square steel pipe mandrel includes a mandrel main body 1, a plurality of support frames 2 and a plurality of retractable reinforced support skeletons 3, the mandrel main body 1 is made of a plurality of square steel pipes 4 Surrounding the hollow octagonal prism formed, the plurality of support frames 2 and the plurality of retractable reinforced support frames 3 are arranged at intervals along the length direction of the mandrel body 1 in the hollow of the mandrel body 1, and the support frames 2 and the retractable The retractable rei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com