Semi-automatic multifunctional fast-screwing spanner

A multi-functional, semi-automatic technology, applied to wrenches, screwdrivers, manufacturing tools, etc., can solve problems such as slow adjustment of adjustable wrench, low screwing efficiency, and stuck worm gear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

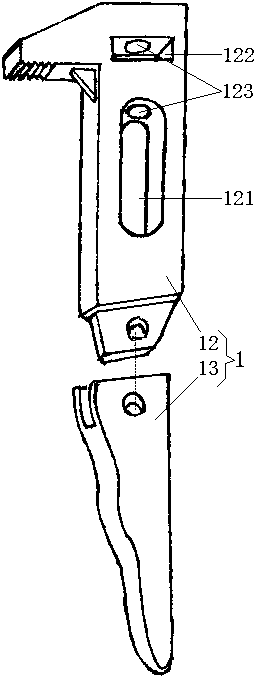

[0025] Such as figure 1 As shown, a semi-automatic multifunctional quick-twist wrench includes an upper lip handle 1 with an upper lip 11 and a lower lip handle 2 with a lower lip 21, and the lower lip handle 2 also has a socket 22 , the lower plate lip handle 2 is socketed and matched with the upper lip handle 1 through the socket part 22. In this embodiment, the socket part 22 adopts a rectangular sleeve, and the upper lip handle 1 is inserted into the socket part 22 , it can form a socket fit that can move up and down. The thickness of the insertion part of the upper pull lip handle 1 should be less than the thickness of the socket 22 opening by about 0.5mm to ensure smooth movement up and down. After the socket fit, the upper pull lip 11 and A wrench opening is formed between the lower lip 21, and there is a gap between the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com