Calibrating device and calibrating method for contact online detection system of lathe

A detection system and calibration device technology, which is applied in general control systems, control/adjustment systems, measurement/indicating equipment, etc., can solve problems such as inability to calculate installation errors, save materials, avoid interference, and reduce occupied space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

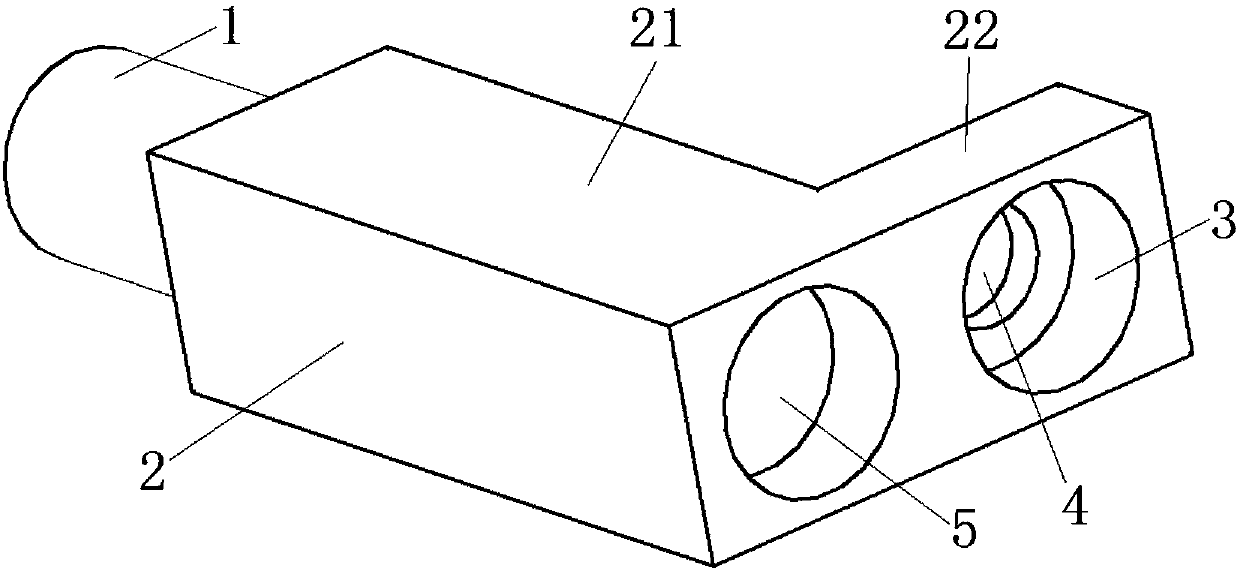

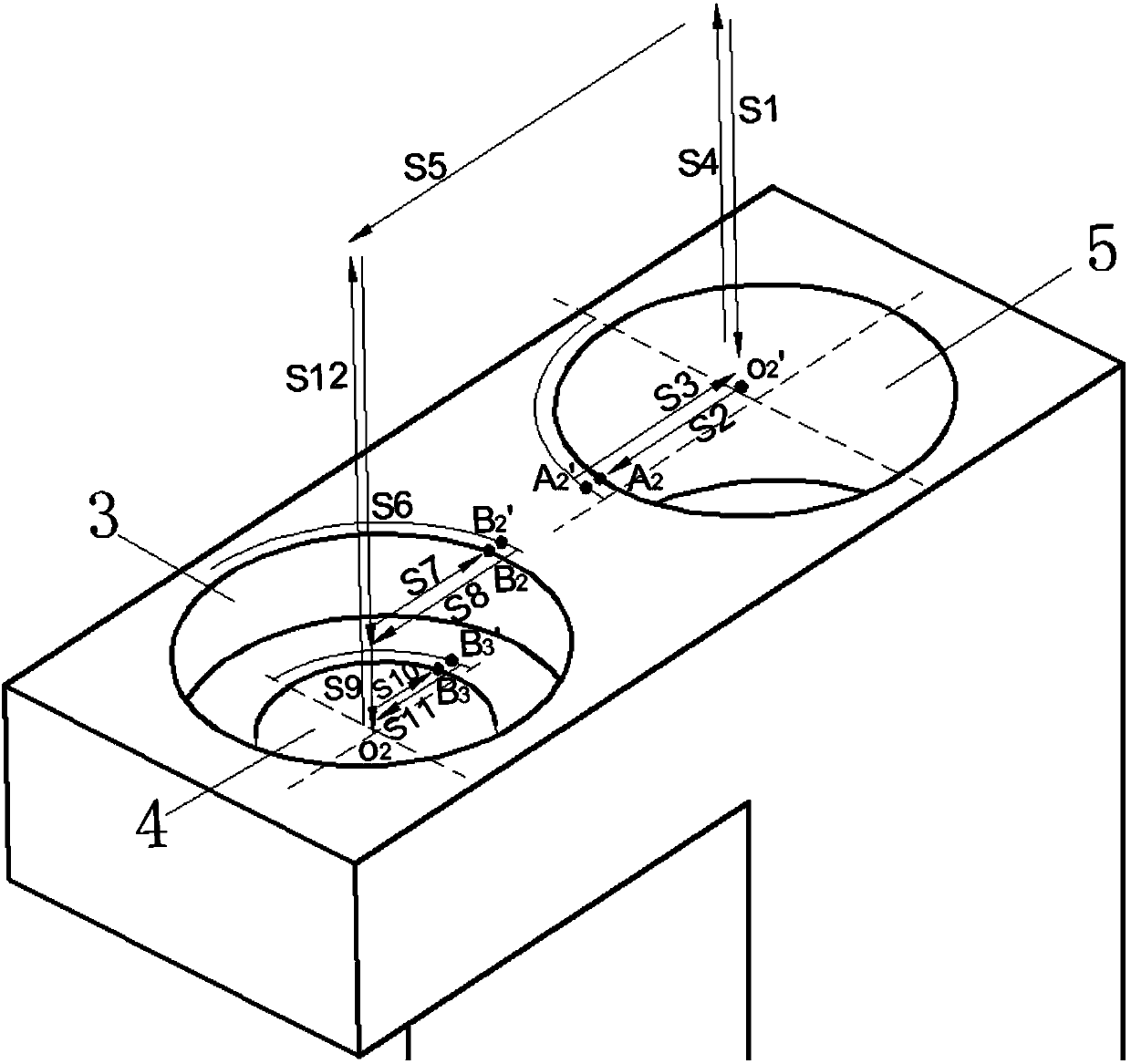

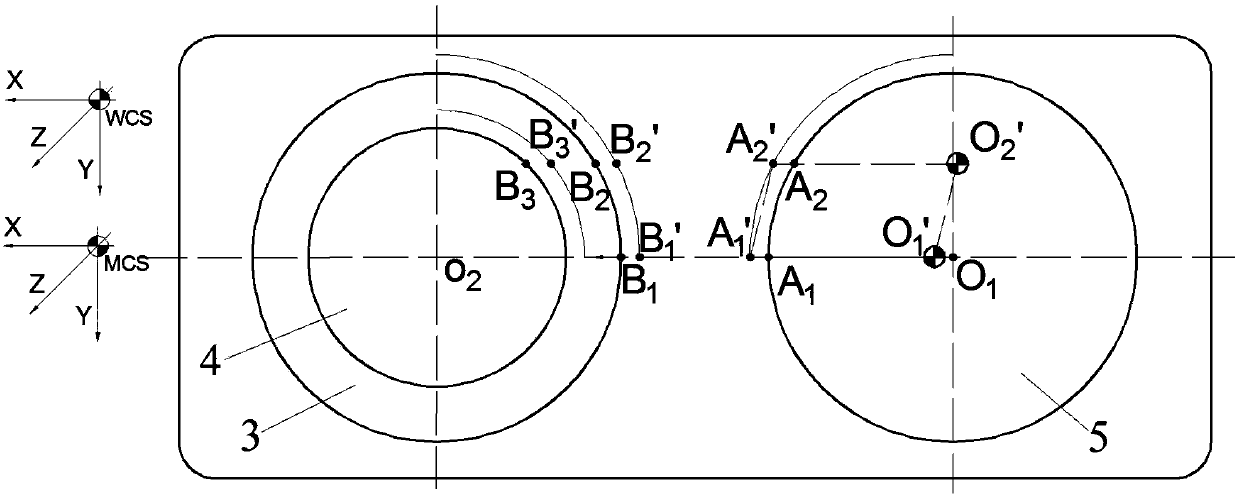

[0032] The present invention provides a calibration device (calibration device for short) used in a contact-type online detection system of a lathe, which is characterized in that the calibration device is integrally processed from one piece of material, including a clamping shaft 1 and an L-shaped device main body 2; The clamping shaft 1 is a cylinder, one end of which is used for lathe chuck clamping, fixed on the three-jaw chuck of the lathe, and the other end is connected with the top end of the long side 21 of the L-shaped device main body, and the center of the clamping shaft 1 The axis is collinear with the center line of the long side 21 of the L-shaped device main body; the bottom end of the L-shaped device main body 2 has a stepped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com