A method and device for controlling strip shape

A technology for controlling strips and steel strips, which is applied in the field of metallurgical cold rolling, and can solve problems such as flatness of flatness not meeting the target requirements, strip deviation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

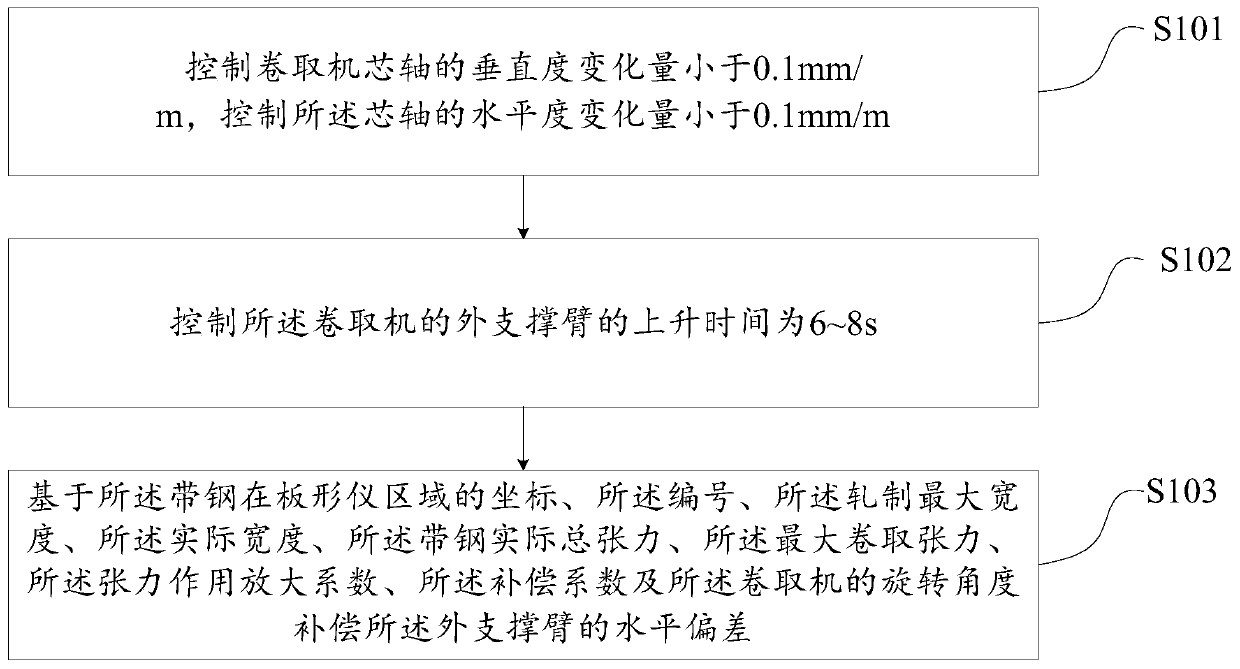

[0041] This embodiment provides a method for controlling the strip shape, such as figure 1 As shown, the method includes:

[0042]S101, controlling the variation of the verticality of the coiler shaft to be less than 0.1mm / m, and controlling the variation of the horizontality of the mandrel to be less than 0.1mm / m;

[0043] In this step, in order to reduce the amount of change in the position of the mandrel before and after the large plate of the coiler rotates, the change in the verticality of the mandrel of the coiler is controlled to be less than 0.1mm / m, and the change in the level of the mandrel is controlled to be less than 0.1mm / m.

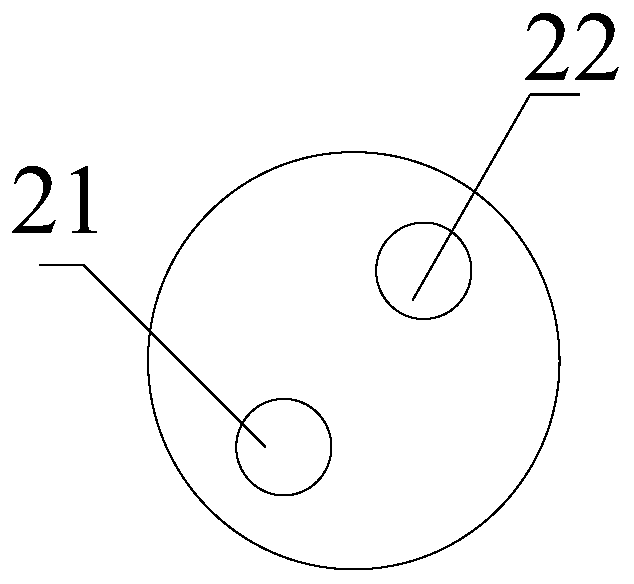

[0044] Specifically, see figure 2 , the mandrel includes a first mandrel 21 and a second mandrel 22, and the operation side entrances of the first mandrel 21 and the second mandrel 22 all have outer support arms. In this embodiment, the operation of each outer support arm A gasket is added at the side entrance to control the variation ...

Embodiment 2

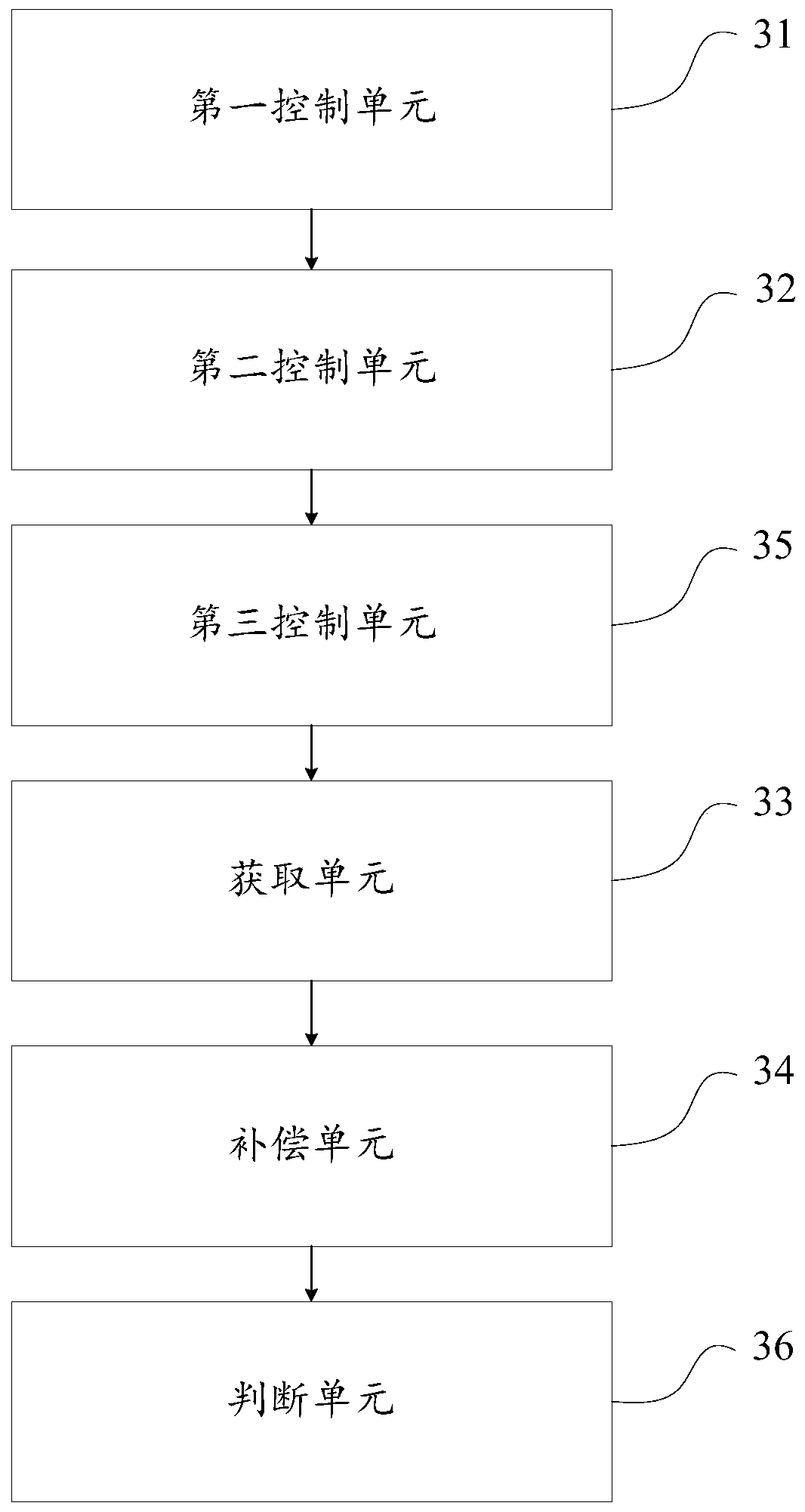

[0058] Corresponding to Embodiment 1, this embodiment provides a device for controlling the strip shape, such as image 3 As shown, the device includes: a first control unit 31, a second control unit 32, an acquisition unit 33, a compensation unit 34, a third control unit 35 and a judgment unit 36; wherein,

[0059] In order to reduce the amount of change in the position of the mandrel before and after the coiler large plate rotates, the first control unit 31 is used to control the change in the verticality of the mandrel of the coiler to be less than 0.1mm / m, and to control the change in the level of the mandrel Less than 0.1mm / m.

[0060] Specifically, see figure 2 , the mandrel includes a first mandrel 21 and a second mandrel 22, and the operation side entrances of the first mandrel 21 and the second mandrel 22 all have outer support arms. In this embodiment, the operation of each outer support arm A shim is added at the side entrance, and the first control unit 31 contr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com