Tea leaf stir-frying and drying device

A drying device and tea technology, which is applied in tea treatment before extraction, etc., can solve the problem of low drying efficiency of tea, and achieve the effect of simple structure, increased contact area and stable device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

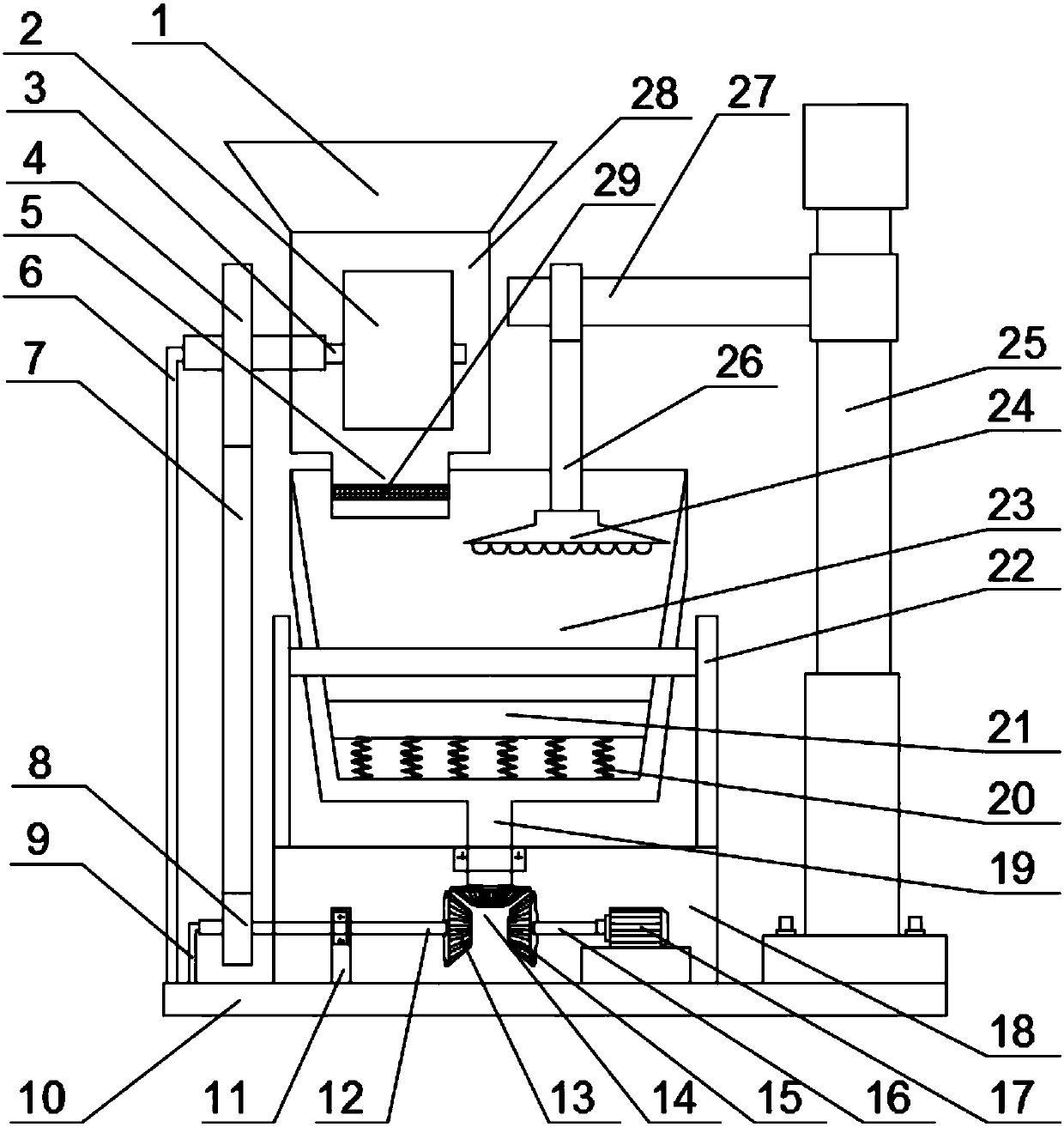

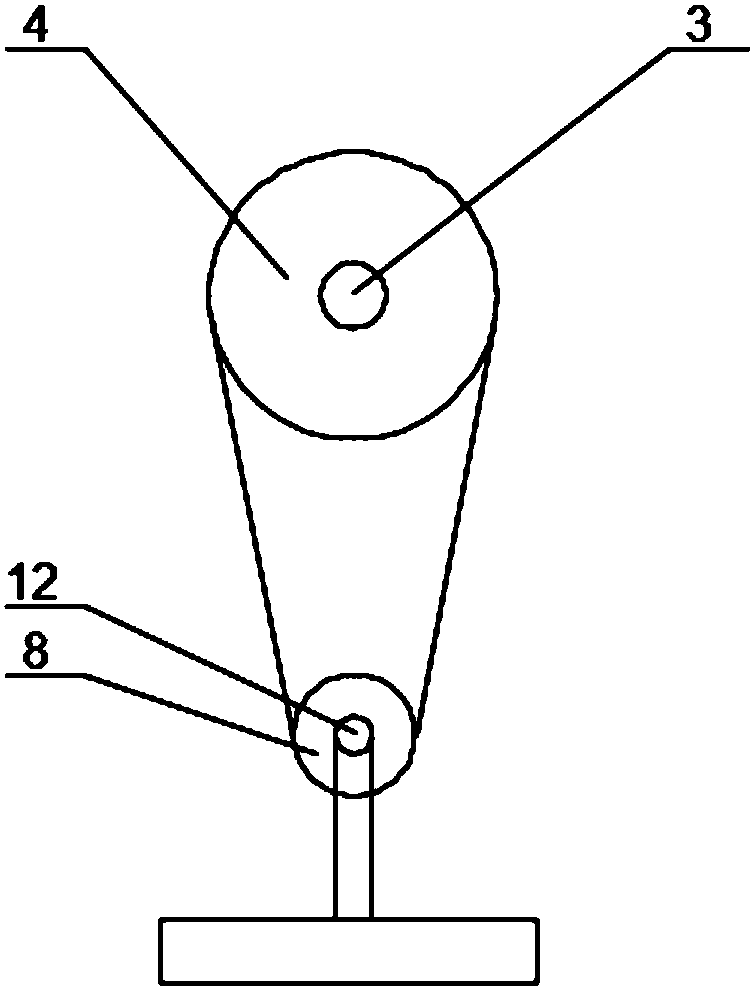

[0023] Such as Figure 1-2 As shown, the present embodiment provides a tea stir frying and drying device, including a base 10, a column 25, a drying box 23, and a motor box 18. The base 10 is provided with a motor box 18, and the inside of the motor box 18 is A motor 17 is provided, and the output shaft of the motor 17 is connected with a rotating shaft 16, and the end of the rotating shaft 16 is provided with a bevel gear 15, and the upper end of the bevel gear 15 is provided with a gear that meshes with the bevel gear 15. Bevel gear two 14, the upper end of the bevel gear two 14 is provided with a rotating shaft two 19, the end of the rotating shaft two 19 is connected with a drying box 23, the base 10 is provided with a column 25, and the column 25 is provided with a There is a cross bar 27, the cross bar 27 is covered with a connecting rod 26, the end of the connecting rod 26 is provided with a drying cover 24, the top of the drying box 23 is provided with a fried tea box ...

Embodiment 2

[0026] Such as Figure 1-2 As shown, the present embodiment is further optimized on the basis of embodiment 1, and the specific implementation scheme is as follows:

[0027] A rebound plate 21 is arranged inside the drying box 23 , and a spring assembly 20 is arranged between the bottom of the rebound plate 21 and the bottom of the drying box 23 .

[0028]In this embodiment, while the drying box is continuously rotating, a spring set is arranged between the bottom of the drying box and the rebound plate in the drying box. Due to its own gravity, the tea leaves on the rebound board vibrate up and down under the action of the elastic potential energy of the spring under the rebound board, and at the same time continuously rotate, so that the tea leaves are turned inside the rebound board, increasing the contact area between the tea and the hot air. Improve the drying efficiency of tea.

Embodiment 3

[0030] Such as Figure 1-2 As shown, the present embodiment is further optimized on the basis of embodiment 2, and the specific implementation scheme is as follows:

[0031] A layer of screen 29 is arranged inside the discharge port 5 .

[0032] In this embodiment, the tea leaves added from the feed hopper are uneven, and the tea leaves with smaller leaves first fall from the screen and fall into the drying box for preliminary drying. At this time, the stir-frying plate is still The remaining tea leaves are stir-fried. When the fine tea leaves reach a certain degree of drying requirements, these fine tea leaves can be taken out from the drying box for post-processing, which further achieves the purpose of separating tea leaves and finely crushed tea leaves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com