Stirred fermented milk and preparation method thereof

A fermented milk, stirring technology, applied in dairy products, milk preparations, applications, etc., can solve problems such as poor taste and flavor, poor rice flavor, and inability to achieve process equipment, and achieves fine texture, rich rice flavor, fine-textured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A method for preparing stirred fermented milk. The fermented milk comprises raw materials in the following mass ratios: puffed rice flour 1.0-5.0%, enzymolysis rice flour 0-20.0%, starter 0.001-0.006% and raw milk supplemented to 100.0%, Its preparation method comprises the following steps:

[0027] (1) Mix the raw material milk, puffed rice flour, and enzymatic rice flour evenly to obtain material A;

[0028] (2) Material A is homogenized, sterilized, and cooled to obtain material B;

[0029] (3) Inoculate the starter in material B, and obtain material C after fermentation;

[0030] (4) Fill material C, cool and cook.

[0031] The puffed rice flour and the enzymolysis rice flour in the fermented milk raw material of the present invention form swollen amylose after fermentation, can provide satiety, and contain vegetable protein, add to fermented milk to obtain a kind of double protein fermented milk.

[0032] Wherein, the puffed rice flour is preferably puffed brown...

Embodiment 1

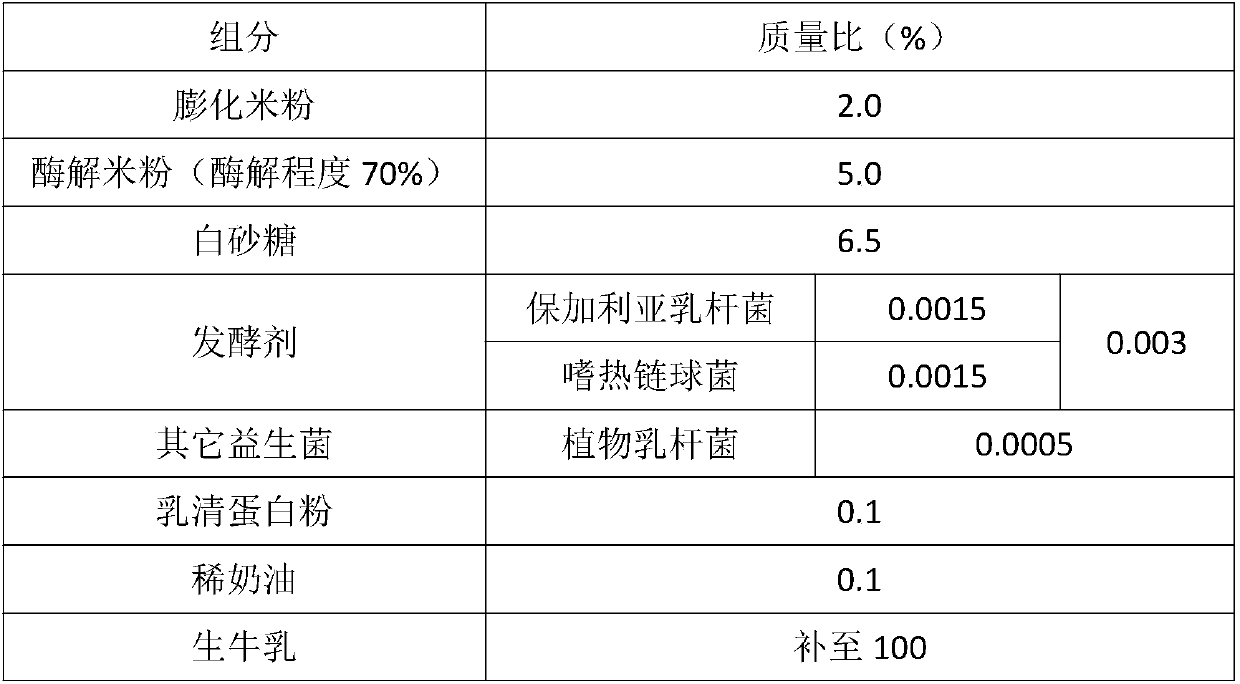

[0053] A kind of stirring type fermented milk, it comprises raw material component and mass ratio as shown in table 1:

[0054] Table 1

[0055]

[0056] The preparation method of this stirring type fermented milk comprises the steps:

[0057] (1) Dissolve puffed rice flour, enzymolyzed rice flour, white sugar, whey protein powder and cream in raw milk at 50°C according to the above ratio, and stir for 15 minutes to obtain material A;

[0058] (2) Homogenize the material A, wherein the first-stage homogenization pressure is 17MPa, the second-stage homogenization pressure is 3MPa, and the homogenization temperature is 68°C. After homogenization, it is sterilized at 95°C for 5 minutes, and then cooled to 37°C to obtain the material B;

[0059] (3) Inoculate starter and other probiotics in material B at an inoculation temperature of 37°C, ferment at 37°C until the final acidity is 70°T, and ferment for 7 hours to obtain material C;

[0060] (4) Fill the material C, the fill...

Embodiment 2

[0063] A kind of stirring type fermented milk, it comprises raw material component and mass ratio as shown in table 2:

[0064] Table 2

[0065]

[0066] The preparation method of this stirring type fermented milk comprises the steps:

[0067] (1) Dissolve puffed rice flour and enzymolyzed rice flour in raw milk at 40°C according to the above ratio, and stir for 30 minutes to obtain material A;

[0068] (2) Homogenize the material A, wherein the first-stage homogenization pressure is 16MPa, the second-stage homogenization pressure is 3MPa, and the homogenization temperature is 65°C. After homogenization, sterilize at 85°C for 10 minutes, and then cool to 45°C to obtain the material B;

[0069] (3) inoculate the starter in the material B, the inoculation temperature is 45°C, ferment at 45°C until the terminal acidity is 65°T, the fermentation time is 4h, and the material C is obtained;

[0070] (4) Fill the material C at a filling temperature of 16°C, cool the fermented m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com