Simple equipment capable of cutting spare ribs into blocks

A simple, spare-rib technology, applied in the direction of deboning shears / bone crushers, etc., can solve the problems of time-consuming and laborious chopping, noise in shopping malls, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

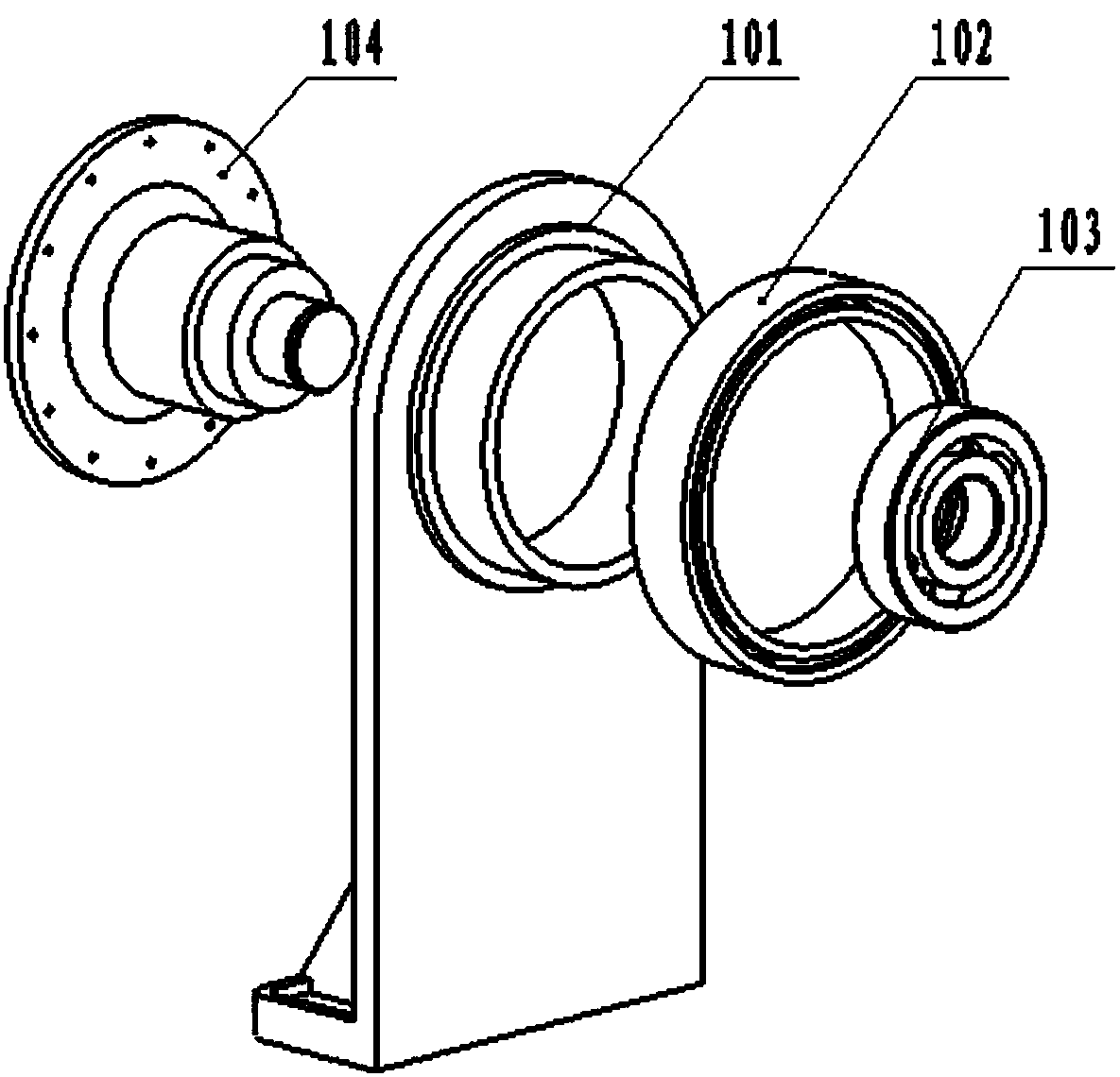

[0030]A simple chopping equipment for pork ribs, which is composed of a front support component 1, an intermediate support component 2, a rear support component 3, a pork rib container 4, a rear interface plate 5, a rear pulley component 6, a cutting belt 7, and a rib block The ejection assembly 8, the cutting hob 9, the synchronous belt 10, the synchronous wheel 11, the reducer 12, the motor 13, the motor bracket 14, the front pulley assembly 15, the cutting plate assembly 16 and the hob ejection assembly 17, The front-end support assembly 1 is made up of a small bracket 101, a large bearing 102, a small bearing 103 and a front-end interface plate 104, and the front-end pulley assembly 15 is composed of a flat key 152 and a front-end pulley 151, through which the front-end pulley on the front-end pulley 151 The keyway 153 and the flat key 152 are connected together with the front interface plate 104, the motor 13 is fixedly connected with the reducer 12, the flange of the redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com