An oilfield water injection simulation experiment platform

A simulation experiment, oilfield water injection technology, applied in wellbore/well components, production fluid, earthwork drilling and other directions, can solve the problems of complex structure, energy consumption, large geographical span, etc., to facilitate regular maintenance and repair, convenient Maintenance and management, easy adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be further described below in conjunction with accompanying drawing:

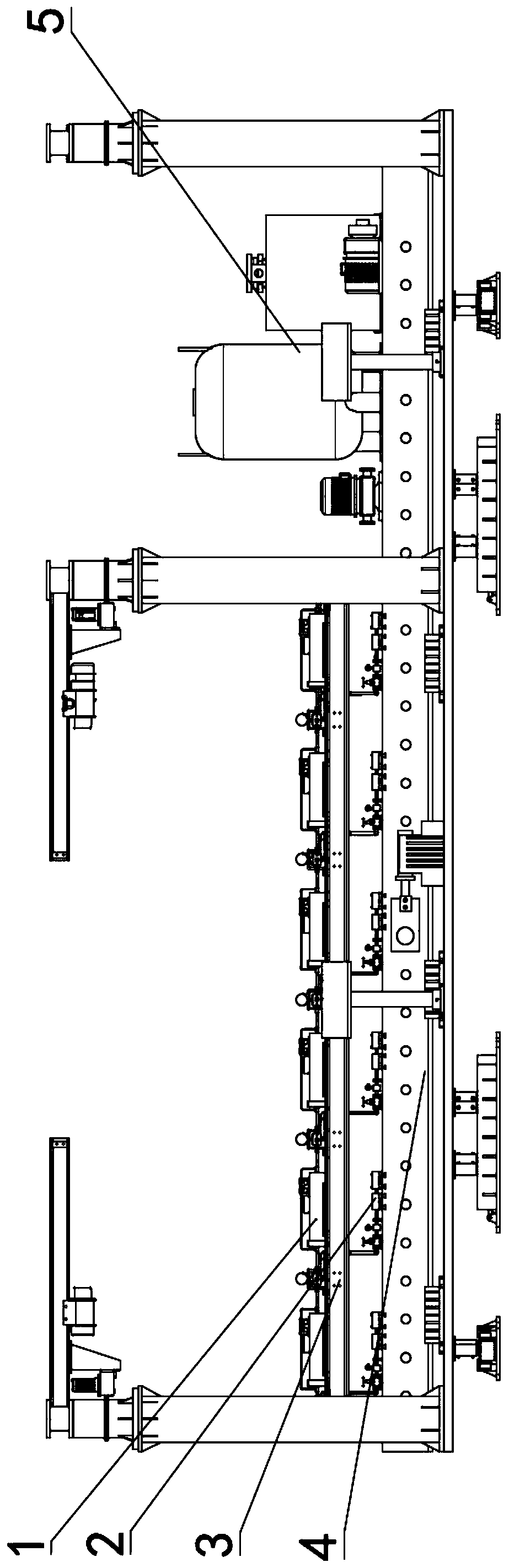

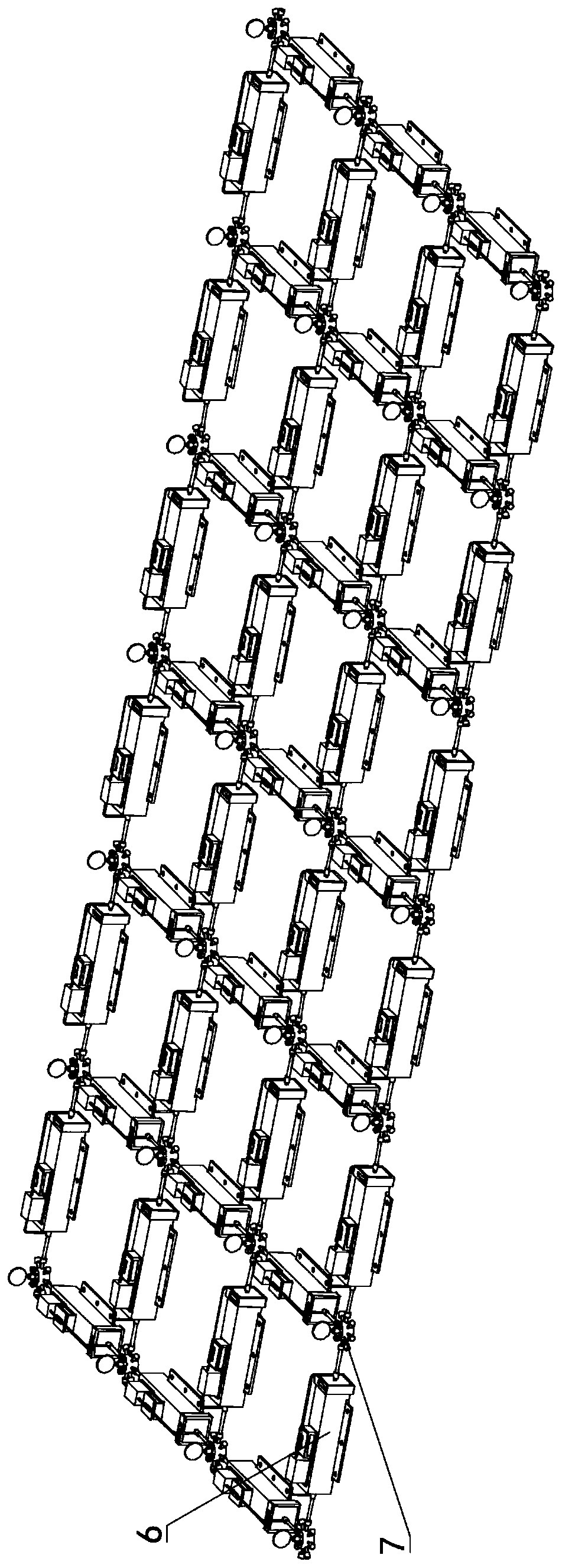

[0072] Depend on Figure 1 to Figure 42 As shown, this oilfield water injection simulation experiment platform includes a pipe network system 1 , a simulated well system 2 , a supporting frame structure 3 , a chassis mechanism 4 and a workstation 5 .

[0073]Among them, the chassis mechanism 4 provides an installation location for the entire experimental platform, and can drive the entire experimental platform to move; the supporting frame structure 3 is installed on the chassis mechanism 4 through its hydraulic column unit 17, and provides a fixed installation location for the pipe network system 1; The pipe network system 1 is installed on the supporting frame structure 3 through bolts, and the simulated well system 2 is installed on the upper chassis 48 of the chassis mechanism 4 .

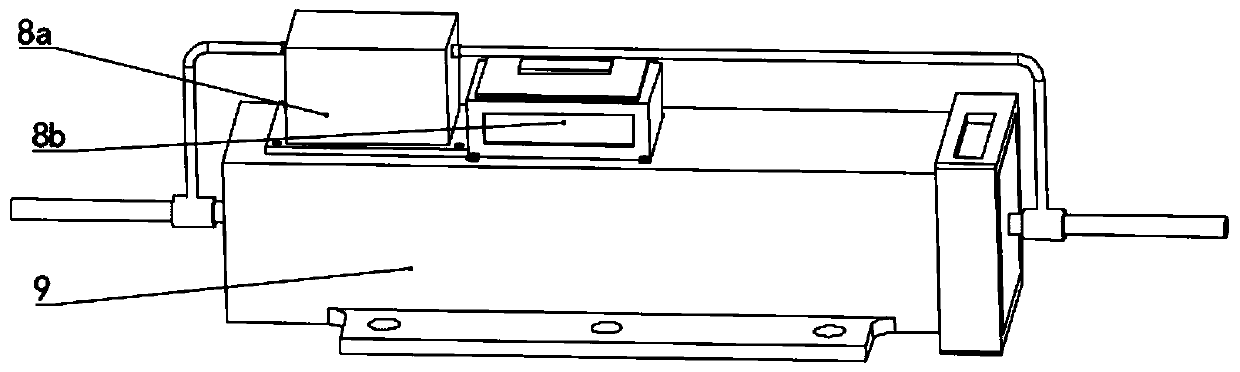

[0074] The pipe network system includes several spiral pipe units 6 and a multi-way val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com