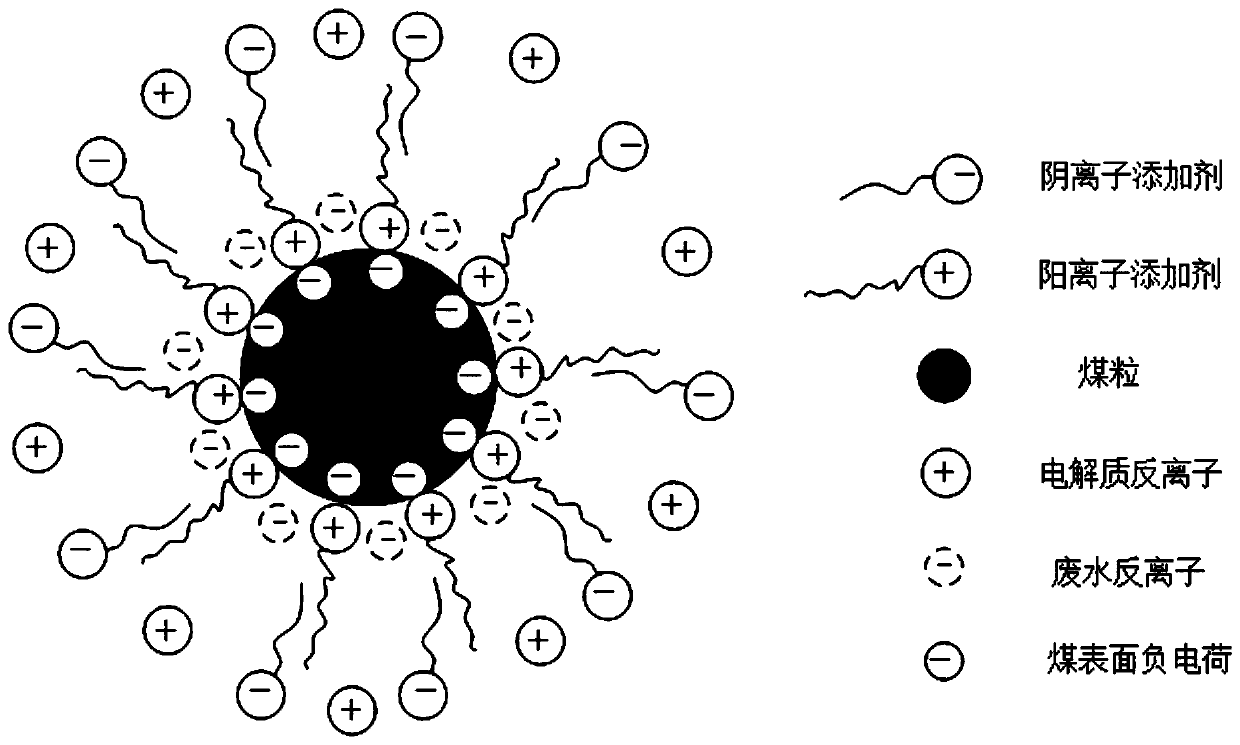

A method for preparing coal-water slurry by using coal chemical wastewater and coal-water slurry additives

A technology for preparing coal chemical wastewater and additives, applied in fuel additives, petroleum industry, liquid carbon-containing fuels, etc., to achieve the effects of turning waste into wealth, zero emissions, and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

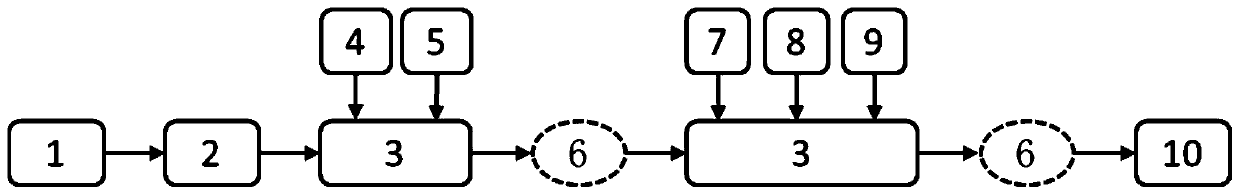

Method used

Image

Examples

Embodiment 1

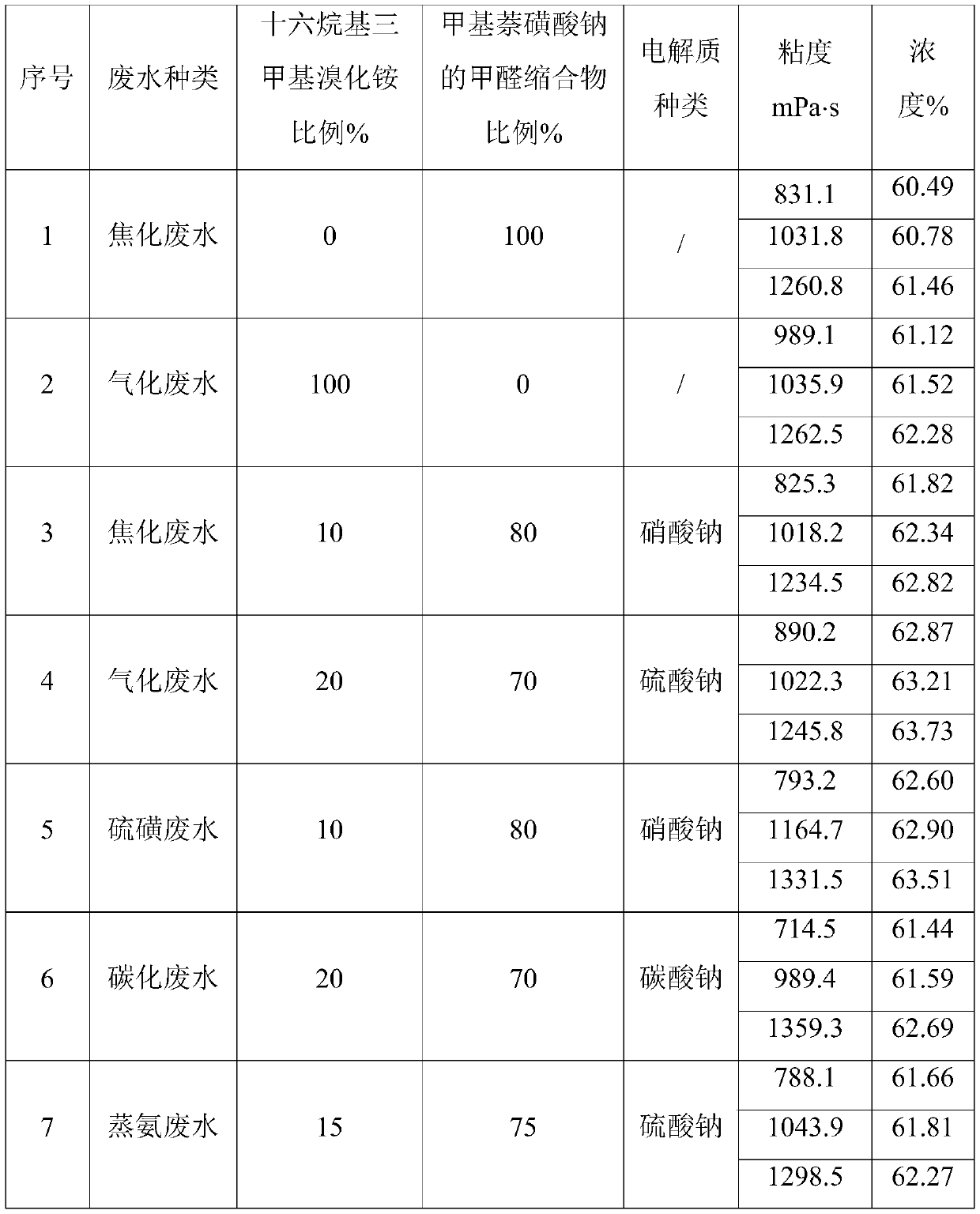

[0034] The additive here only adopts the formaldehyde condensate of sodium methyl naphthalene sulfonate. It is preset that the proportion of pulverized coal is 60%, the weight of wastewater is 39.65%, and the weight of additives is 0.35%. Coal coking wastewater is used to prepare 50g of coal-water slurry. The results are shown in group No. 1 in Table 1. Example 2:

Embodiment 2

[0035] The additive here only adopts cetyltrimethylammonium bromide. Preset coal powder weight ratio is 60%, wastewater weight ratio is 39.65%, additive weight ratio is 0.35%, coal gasification wastewater is used to prepare 50g coal water slurry. The results are shown in group No. 2 in Table 1.

Embodiment 3

[0037] Additive adopts the weight ratio composition of 10% hexadecyltrimethylammonium bromide, the formaldehyde condensate of 80% sodium methylnaphthalene sulfonate and 10% sodium nitrate here, adding method is as previously mentioned, wherein first added Part of the waste water accounts for 85%, and the remaining waste water accounts for 15%. It is preset that the proportion of pulverized coal is 61%, the weight of wastewater is 38.6%, and the weight of additives is 0.40%. Coal coking wastewater is used to prepare 50g of coal-water slurry. Add hexadecyltrimethylammonium bromide, coal powder, and some waste water, mix them, stir for 30 minutes, and let stand for 60 minutes. The results are shown in group 3 in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com