Light emitting diode epitaxial wafer preparation method and light emitting diode epitaxial wafer

A technology for light-emitting diodes and epitaxial wafers, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of poor consistency of light-emitting diode epitaxial wafers, and achieve the effects of avoiding different photoelectric properties, improving consistency, and reducing time consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The embodiment of the present invention provides a method for preparing a light-emitting diode epitaxial wafer, see figure 1 , the preparation method comprises:

[0041] Step 101: growing a buffer layer on a substrate.

[0042] Specifically, the substrate can be sapphire with [0001] crystal orientation.

[0043] Optionally, before step 101, the preparation method may also include:

[0044] The temperature is controlled at 1000° C. to 1200° C., the substrate is annealed in a hydrogen atmosphere for 8 minutes, and nitriding treatment is performed to clean the substrate.

[0045] Specifically, this step 101 may include:

[0046] The temperature is controlled at 400° C. to 600° C., the pressure is 400 Torr to 600 Torr, and a gallium nitride layer with a thickness of 15 nm to 35 nm is grown on the substrate to form a buffer layer.

[0047] Optionally, after step 101, the preparation method may further include:

[0048] The temperature is controlled to be 1000° C. to 120...

Embodiment 2

[0097] The embodiment of the present invention provides a method for preparing a light-emitting diode epitaxial wafer, see image 3 , the preparation method comprises:

[0098] Step 201: providing a substrate laminated with a buffer layer.

[0099] Specifically, in step 201, the substrate obtained in step 108 and step 109 in the first embodiment with a buffer layer laminated thereon can be used.

[0100] Step 202: growing a first undoped GaN layer on the buffer layer.

[0101] Specifically, if there is no first undoped gallium nitride layer on the buffer layer stacked on the substrate in step 201, then this step 202 can be the same as step 102 in Embodiment 1, and will not be described in detail here. If the first undoped gallium nitride layer is also laminated on the buffer layer stacked on the substrate in step 201, the thickness of the grown first undoped gallium nitride layer can be correspondingly reduced, so that the grown in step 202 The sum of the thickness of the f...

Embodiment 3

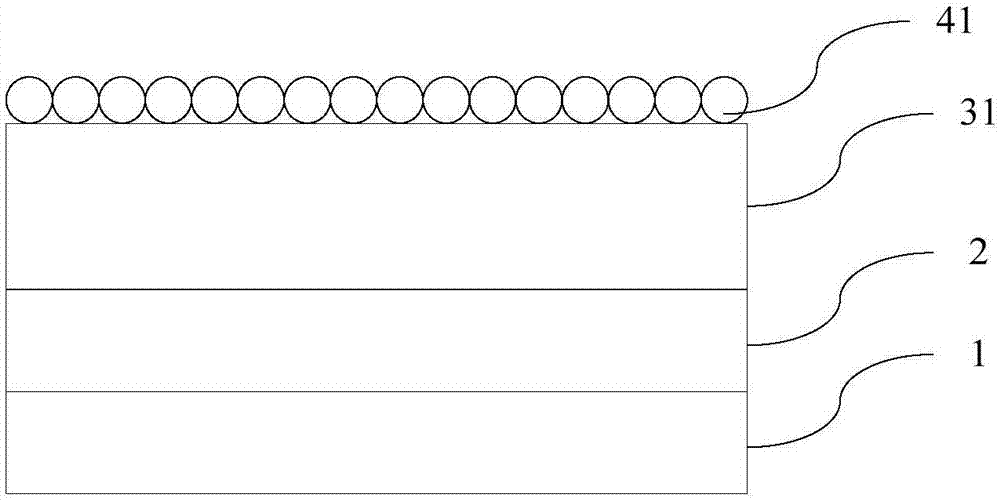

[0119] The embodiment of the present invention provides a light-emitting diode epitaxial wafer, which can be prepared by the preparation method provided in the above-mentioned embodiment 1 or embodiment 2. Specifically, see Figure 4 , the light-emitting diode epitaxial wafer includes a buffer layer, a first undoped gallium nitride layer, a colloidal crystal film, an oxide film, a second undoped gallium nitride layer, an N-type nitride layer, and a buffer layer sequentially stacked on the substrate. Gallium nitride layer, multi-quantum well layer, electron blocking layer and P-type gallium nitride layer.

[0120] In this embodiment, the colloidal crystal thin film includes a plurality of organic particles arrayed on the first undoped gallium nitride layer, and the oxide thin film is disposed on and between the plurality of organic particles.

[0121] Optionally, the diameter of the organic particles may be 0.5 μm˜1.8 μm. If the diameter of the organic particles is less than ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com