A device capable of automatically detecting the airtightness of an exhaust manifold and its application method

An exhaust manifold, automatic detection technology, applied in the field of auto parts, can solve the problems of high professional quality requirements of operators, inability to accurately determine the leakage point, affecting the use effect, etc., to achieve strong operability and leak detection. The effect is obvious and the operation is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

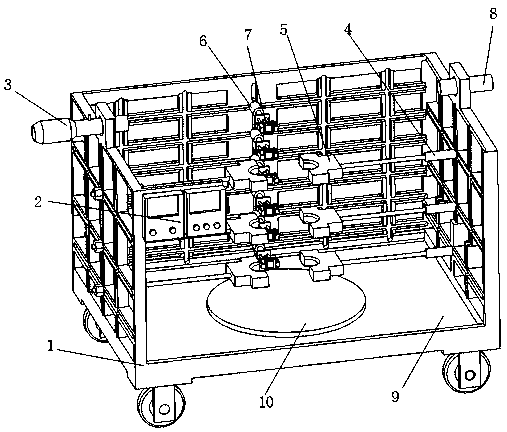

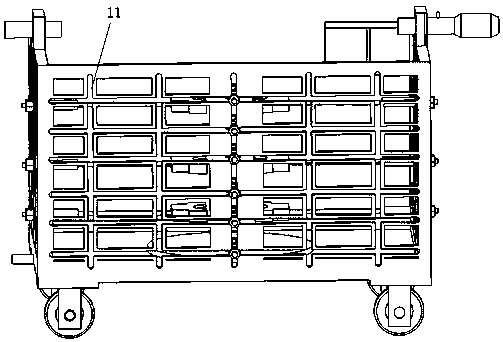

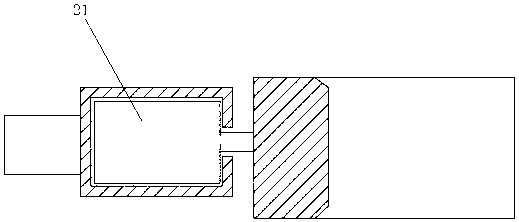

[0032] A device that can automatically detect the airtightness of an exhaust manifold, including a detection car 1, a starter and an alarm 2; the three sides of the detection car 1 are provided with a plurality of vertical and horizontal slides 11, and the vertical and horizontal slides 11 are inward Stretch out a plurality of clamping devices 5, and sealing device 7 with hook claw 16; Described clamping device 5 and sealing device 7 are connected with power unit respectively, and the tail of described power unit runs through vertical and horizontal slideway 11, and in described vertical and horizontal Move on the slideway 11; the detection car 1 is provided with an automatic water injection pipe 8 and an automatic gas delivery pipe 3; the starter and the alarm 2 are arranged on the outside of the detection car, and are connected to the control system through sensors. The power unit includes a hydraulic cylinder one 4 and a hydraulic cylinder two 6; the hydraulic cylinder one 4...

Embodiment 2

[0036] The second embodiment is basically the same in structure and principle as the first embodiment, except that the clamping device 5 and the support base 10 are provided with electromagnetic coils inside. After placing the branch port of the exhaust manifold to be tested upright on the support base 10, the clamping device 5 and the electromagnetic coil inside the support base 10 are energized to form an electromagnet, which attracts the exhaust manifold to initially fix the exhaust manifold to be tested. exhaust manifold.

Embodiment 3

[0038] The third embodiment is basically the same in structure and principle as the first embodiment, except that the automatic gas delivery pipe 3 is provided with a high-power heating wire 19 and a pressure relief valve 20 inside. After completing the leak detection, open the pressure relief valve to release the pressure 20, discharge the water in the exhaust manifold, start the high-power heating wire 19, blow hot air into the exhaust manifold, and dry the residual moisture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com