An Integrated Mining Technology with No Drilling and No Coal Pillar

A coal-pillar-free, integrated technology, applied in ground mining, earth square drilling, underground mining, etc., can solve the problems of waste of resources, low production efficiency, waste of coal resources, etc., to reduce production costs, improve resource recovery, increase The effect of business economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings, but this does not mean to limit the protection scope of the present invention.

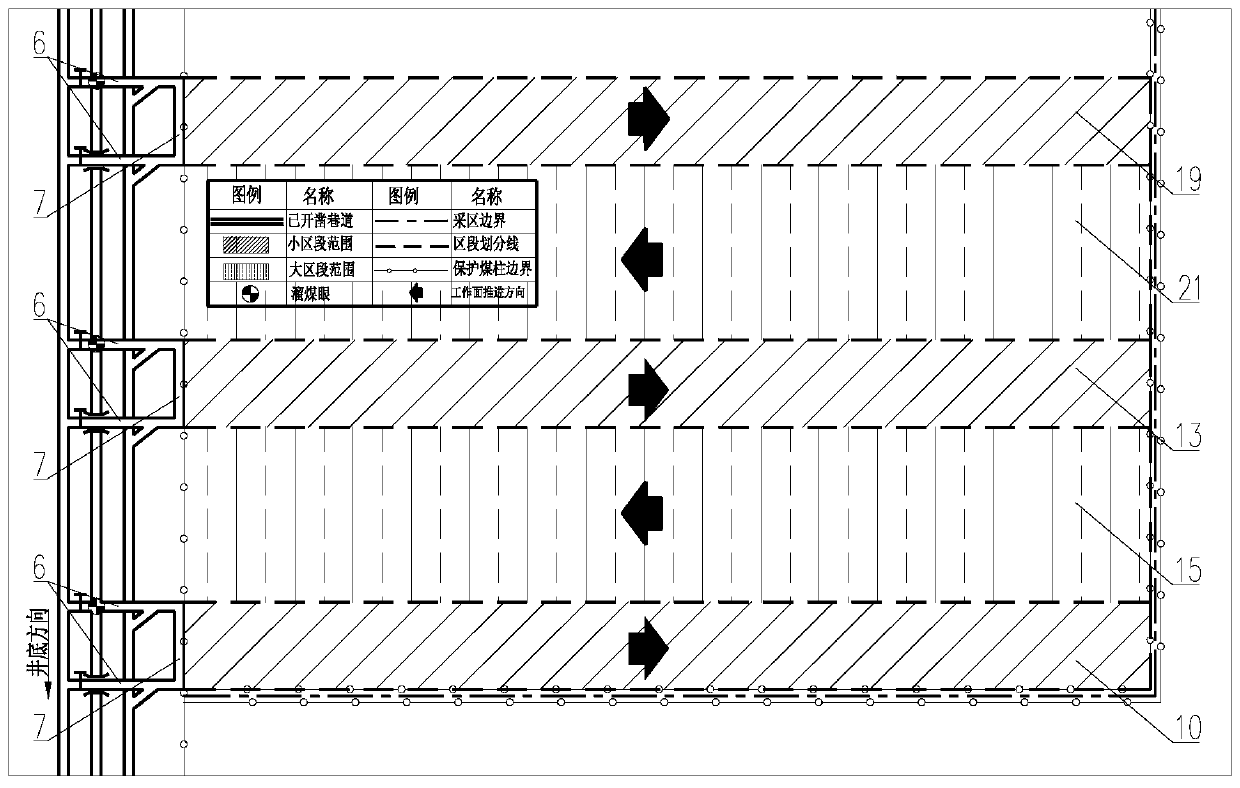

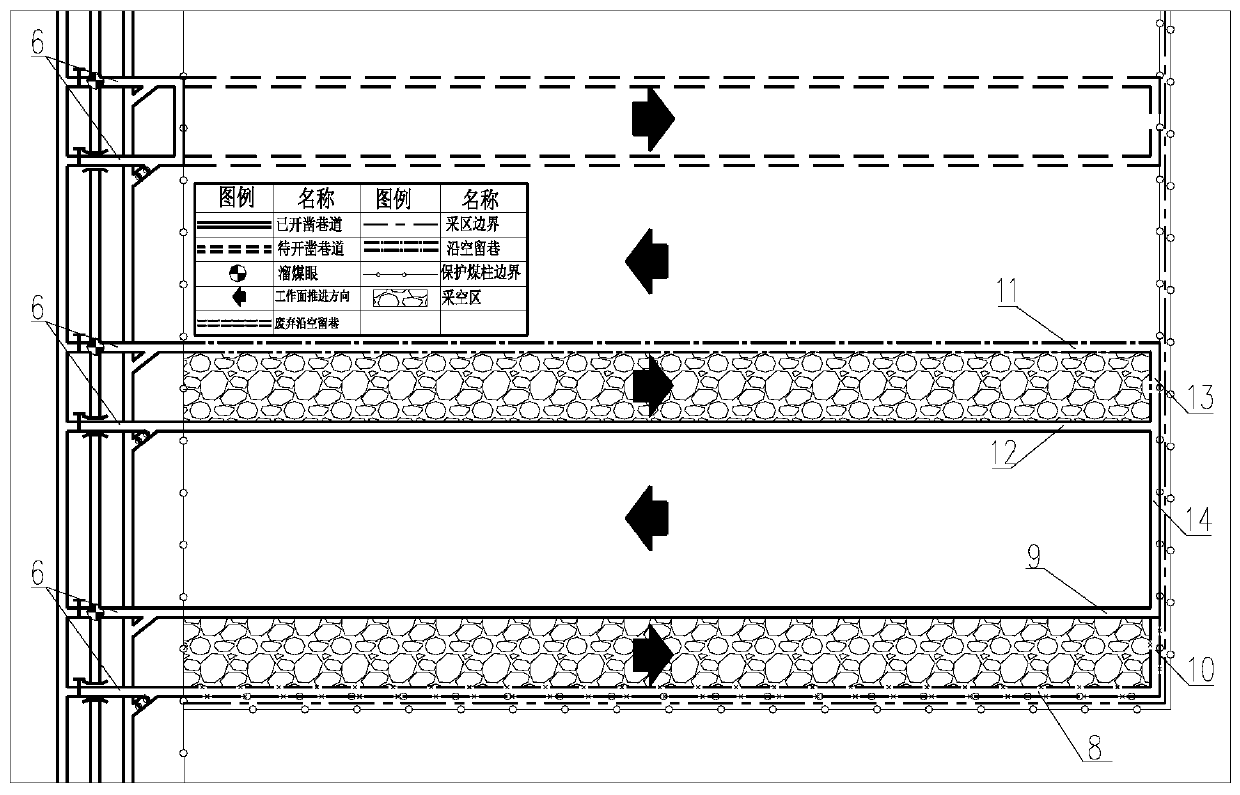

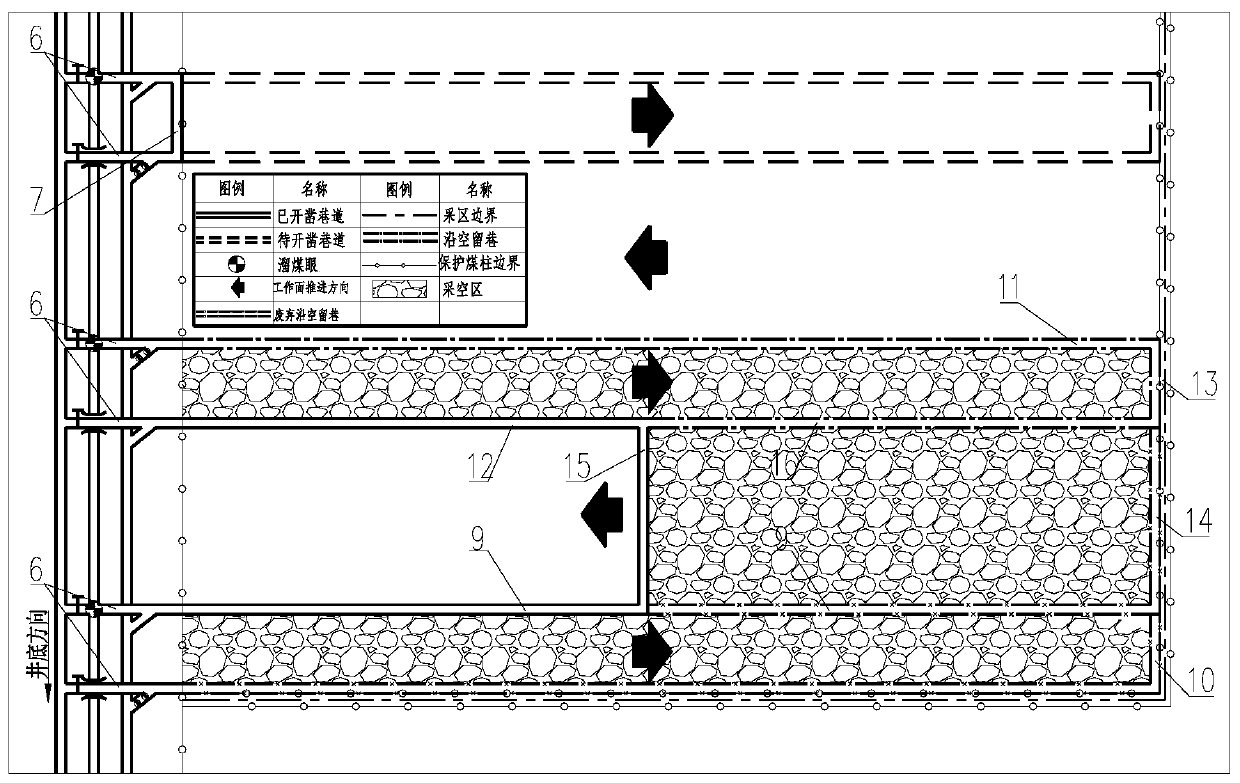

[0034] Such as figure 1 As shown, the present invention provides an integrated mining process without tunneling and coal pillar mining and retention. The selected coal seam is selected for the first mining with stable occurrence, small coal seam dip angle, proven geological structure, uncomplicated mining area, and good hydrogeological conditions. Divide the mining area into several large section working faces and several small section working faces, and arrange them alternately according to the small section working faces, large section working faces and small section working faces. According to the actual situation of each mine, the small section The width of the working face is half of the width of the working face in the large section, and the inclin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com